Doing my research with what all fittings im going to need to be ordering/wrapping my head around making everything working. Does this look right?

275 gallon tote

bulkhead fitting from reel to fill tank (what size? 5/8 or half inch?)

Ive seen people put a 90 on it so it shoots the opposite side of where its filling to help with eddys? does that make sense? Connect to hudson float valve.

hose that connects to 275 from to reel (again what size? does it matter?)

reel to garden hose

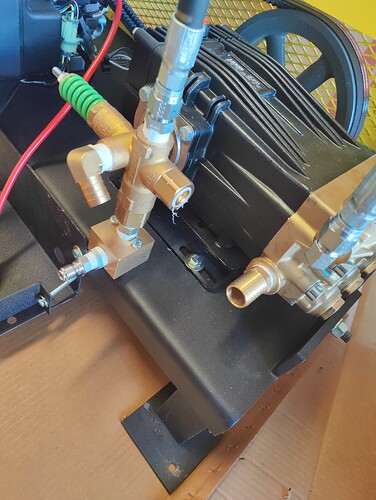

1/2 inch bulkhead fitting and 1/2inch to go from tank to proportioner

Do i need a simple vent for the tote itself? If so, another bulkhead fitting and like 1/4 inch tubing id assume?

On bottom they start as 2 inch so i need to have it reduced to one inch. then have it T’d off with a ball valve. one side going to pressure washer with 1 inch crush proof hose. The other end to a longer hose that can reach out the back of the truck to be able to drain if needed. I am unsure if a 90 degree is the way to go right from here with a 1 inch. would that reduce flow too much?

55 SH tank

Going to need two bulkhead fittings, one for DSing, and the other for Proportioner/soft wash.

DS is 1/2inch bulkhead fitting and then a 1/4 inch barb for DS hose.

soft wash bulkhead is 1/2 inch to 1/2inch barb to proportioner.

Another 1/2 inch bulkhead to 1/4 inch barb for venting that loops down through floor.

7 Gallon Surfactant Tank

1/2 inch bulkhead fitting to 1/4 inch barb to proportioner.

For proportioner i was thinking…

with a 3 way flush addon to be able to clean out everything.

That way i could run 1/2 inch water into proportioner and use half inch hose for softwash reel and hose.

Does this sound right to you? Have i missed anything? (EVERYTHING  )

)

Ok, don’t feed the tank from the garden hose reel. Way to much restriction. From the top of the tank run a 1 inch line from bulkhead fitting a couple of feet long with a garden hose adapter and a garden hose ball valve(Gilmore large bore) pull off hose from reel and connect to the jump line to tank. Feed machine with 1 inch line. I wouldn’t worry with a Hudson valve. To much restriction. Use the ball valve at the tank to stop or slow water if you need to.

I’ve never seen the need for a proportion system or 12v system, but if you need it, unscrew the top on the bleach tank and drop a pickup tube down in it.

With you not wanting to do roofs I’m not surprised! I think I might be a little gunshy with not wanting to batch mix ever again and hoping to have that proportioner for hands free on the fly adjustments for pre/post treating concrete and roofing sounds awful nice in theory if not practicality.

If you’ve never had to open 30 jugs of Costco bleach to pour into a 55 gallon tank and then dispose of 30 jugs for literally just ONE medium sized roof I would just go ahead and take my word for it that it is not the best way to spend an afternoon

I bought about 150 jugs a night for a week at a job in Alabama that I couldn’t find bleach for. Every night when the guys got back to the room I drive to every dollar store, Walmart, grocery store within 50 miles, bought bleach and poured into everyone’s tanks while they slept

1 Like

For my 12v, this is my ‘proportioning valve’ haha. I dump Elemonator straight into the SH tank & have a drop stick / bulkhead on each tank. I’ve switched to poly elbows & poly ball valves since this picture was taken but with both valves wide open, it pulls 7 gallons of water & 5 gallons of SH / Elemonator. So with 12.5 SH, that’s about a 5% mix. It’s easy to adjust from there without any batch mixing. Biggest issue I’ve had with the Hudson valve, it won’t shut off if the supply pressure is too high. I have a 1/2 inch blow off valve on top of the tank so it doesn’t turn into a blimp & explode.

1 Like

Twas the night before christmas at an alabama motel

Not a creature was stirring cept for one muttering “Hell!”

The guys suttners were hung by the worktruck with pride

In hopes that theyd be done working tomorrow outside

The guys were all sleeping in their warm snugly beds

While William ran around buying SH, and ended up on a watchlist of the feds

When out in the parkinglot i heard such a clatter

Sounds like William banged his dang knee on that low lyin ladder

Away to the window I flew in a flash

To see if it was a bump, a bruise, a cut or a gash

The no vacancy light on the breast of the new fallen snow

Gave the luster of mid-day to objects below

When what, to my wondering eyes should appear

The Tanks were all filled, with a liquid that did not look quite clear

William had done it, so lively and plump

I knew in a moment, why they called him the grump!

More rapid than eagles his nimble fingers worked

as he saw me creeping while pouring he yelled “Come help me ya jerk!”

now, SH, be easy, the bleaches making me queasy,

off, lids, be gentle, the trucks only a rental!

to the top of the truck, to the top of the tanks!

Now dash away, dash away, dash away “Thanks!”

He sprang to the truck, and drove off like a missle

And i thought to myself with a whistle,

“Sheesh he drove out of sight”

“hes only halfway done and its three thirty at night!”

7 Likes

Im gonna be honest, i added more, and i have no regrets that i spent a chunk of my afternoon writing this instead of packing my sea bag for work

1 Like

Jingle bells, jingle bells, William’s on his way.

Fills his cart with Wal-Mart bleach & waits in line to pay.

Edit: you highjacked your own thread haha.

1 Like

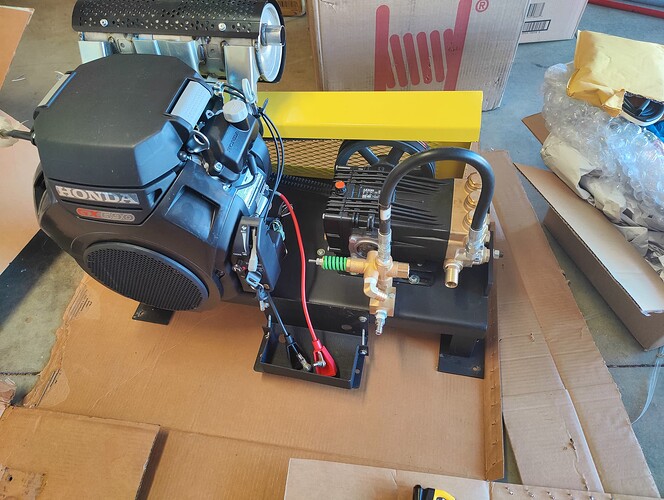

Update:

Bought the box truck. Mechanically seems sound. Still paying to have someone go through it because it will be on penskes dime.

The fuel vent hood or whatever you want to call it was busted up and I’m assuming they will be replacing that so haven’t painted it.

Cleared out and cleaned the truck floor and painted it. I must have brought the cold with me from Alaska. As I was driving from Los Angeles to Arizona it freaking SNOWED. Bought raptor liner and prepped and the temp outside was freezing overnight and maybe 45 during the day. Put a heater in and got to work painting.

Trying to figure out how best to mount pressure washer and on which side. If I’m not running two pressure washer setups do you guys have a reason of one side over the other? Maybe I’m overthinking things. I was going to put it drivers side and have a 24x36 access door cut in.

I need to figure out some sort of way to mount the pressure washer…probably over the wheel well box that maximizes free space. The reason why I chose the drivers side is I was wondering if I was smart enough I could build a frame where I can access the start controls and maybe fit my 12 gallon fuel tank under there so could fuel up the truck as well as that tank on the same side easily.

I’ve seen most builds use metal and welding but idk if I’m able to get that done here without spending a mint. Would I be able to use 2x4 and 3/4 plywood to be able to throughbolt to bottom of floor or would that be too top heavy?

If I can get this up loosely plumbed I can have it welded back while I’m up in Alaska. I’m just wondering if it would work or be dangerous while driving or even using it a summer.

What are your thoughts on drivers side vs passenger side and does it even really matter? Like I said…might be over thinking this one but want to make sure I’m doing it right.

2 Likes

It needs to go on the driver’s side if you want the exhaust to go out the back. A welding shop can handle lengthening the legs on one side in ten minutes. It’s as simple as a cut with the plasma to take the feet off and around 5 inches or so of angle.

Run your finger behind the lip that the battery tray is mounted on. If there are two small holes there my boy made that machine. Template had two holes in the wrong spot

I just took a feel but didn’t feel those holes. That would have been awesome if they did!

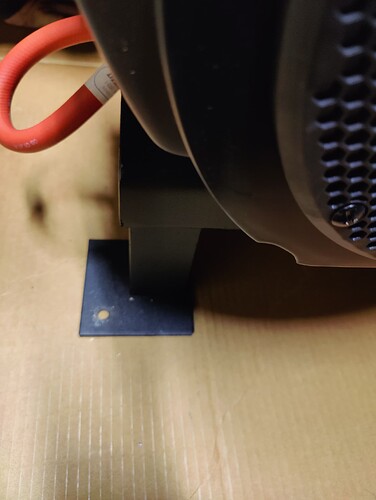

Question about this setup though. Do I need bushings for vibrations? If I through bolted the legs through the floor, would vibration tear it up?

Like here?

Gotta put rubber between those and the floor

1 Like

In no way am I an expert, nor is my setup the correct way to do such things, however some simple angle iron racks have been holding strong and working great. The beauty is unlimited customization is at your finger tips. I was into all the steel for about $300, including expanded metal shelf’s.

knowing how to weld also helps (or a buddy who does) lol

1 Like

What IBS said. Get some vulcanized rubber, it will outlast your equipment, probably the truck, and possibly you. Guy I buy my stuff from sells it all over, it is amazing what it can do.

If you can’t find a hunk, find a used skidsteer/heavy equipment tire and use a sacrificial blade(s) to cut it. Oh yeah, wear a mask.

The problem is the wheel well is wider than that skid so it wouldn’t just be extending it to clear the wheel well in height , it would still be short. Wheel well is 31 inches, skid is about 4 inches shorter. This wheel well is killing me.

I’m not following. Mount one foot or two feet on the wheel well and the remaining feet on the floor of the truck. Ice hey a bunch of those uhual and budget trucks. I think I posted a video here somewhere with a walk thru of the inside.

I can’t see the kitchen sink

Wow you packed a lot in there, what size was that? Looks like a v nose from the pic.

For some reason I thought it was a big no no to put anything on those wheel wells so Ive been avoiding any idea involving putting legs on that. If I was able to do that, that certainly would make my life easier.

![]() )

)