Really need help with this if anyone can diagnose this problem I would appreciate it. I just switched to a 5GPM pump here and corresponding unloader was switched out. (I put a 65 gallon buffer tank as well. Now I’m getting this hop out of the system. I adjust the unloader to take that hop out of the system but when I do that I’m losing water flow at the outlet. When I adjust again to get the proper flow the vibration is there again when the valve is shut off. I can shut off the valve and adjust it to where the system isn’t vibrating but then back to square one when I’m losing water flow or pressure. The first video demonstrates the original problem and the second I am trying to adjust the unloader and getting this circular problem.

For that unloader:

- Put in the tip that corresponds to your machine’s highest pressure rating (or slightly below it)

- Put a quality pressure gauge behind the gun.

- Undo locknut on unloader

- Start with top bolt on unloader all the way out (not out of the top, but like all the way “high”

- Start machine with trigger pulled

- Tighten top bolt until the pressure stops rising in the guage

- Make sure you still have a tiny trickle going into bypass when you’re on the trigger.

There are other weird things to look at if the condition still happens with the unloader properly set.

Wrong orifice size, bypass hose ID too big, etc

I think I got it. The tank was on an angle upward and I think even though I have suction hose going to the pump it was cavitating the pump starving for water.

IDK man, it sure did seem to calm down the second you played with the unloader. Hope it was that easy for ya though!

Didn’t see this response while I was typing Will definitely do this procedure and need to get a pressure gauge. I don’t want to be too confident that the problem is solved so any responses are appreciated.

If you don’t get a pressure gauge it isn’t the end of the world. As long as you adjust until there is only a trickle of water you’re fine, pressure is irrelevant.

The flow-actuated unloaders like he has definitely seem a little more finicky than pressure-trap ones.

There was a thread on FB last summer about someone’s machine fluctuating back and forth into bypass whenever they tried to use their SC, and it turned out they had it set their K7 with a tip that put out just a little lower psi than their SC

I’m agreeing with you, I’m just a bad communicator sometimes. I was trying to say that pressure is definitely irrelevant as long as he uses the correct tip to set it with (a tip close to the machine’s max psi).

When on the gun engine runs normal and psi at 1800 (red tip)-when I go off the gun psi gauge

at 3000 but engine slows way down, unsure if this is how it suppose to run.Any help is appreciated.Have video but can’t upload.

Thanks

That’s about normal

Upload your video to youtube then copy and paste the link here.

Sounds like your unloader is sticking to me but could be a number of things. Does the machine die?

Will try right away.Machine does not die (GX390 with GP TS2011 pump) depending on tip (1200-22000 psi) then always goes back to 3000 when off the gun.

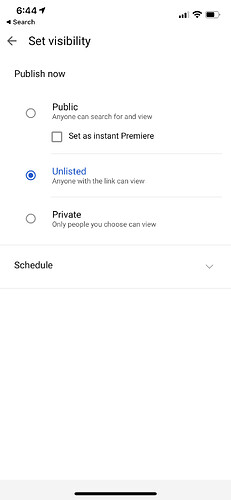

You need to change the video setting to “public” or “unlisted” otherwise we can’t view it.

Do I do that in the youtube channel I just created? First time trying to upload video.

Do you by chance have a clutch setup on that machine?

Do not know.Purchased this at an auction this winter and had to put a new muffler on

and wait for warmer weather (mid Canada) before starting up.Purchased because of belt drive and option for buffer tank as taking this of wheels and putting in back of truck.

Turn it off. Take the belt guard off and take a video of the pulley system. Almost seems like you have a clutch on there that idles it down when off the trigger.