Hold up, are we talking about the same application here? I thought we were talking about mounting to the engine shaft. As in, using anti-sieze on the key and shaft so the whole thing can be pulled off easier. Did I read that wrong?

Also are they talking about a silicone that stays liquid/greasy? I think I misunderstood, and thought you were saying like an RTV high-temp silicone. There’s no way they’re having you caulk that thing in place lol

Jake, they are highly recommending Hi-Temp silicone instead of anti-seize on the shaft & key before mounting the gear box & pump. They mentioned that the anti-seize breaks down and the Hi-Temp silicone does not while keeping water out and they have used it for years. I had to call them again today to confirm.

I hear that and I totally believe you. But I’m worried there might have been a communication breakdown. As in, they might be recommending a high temp silicone grease but not a high temp silicone sealant. See what I mean? One will stay slippery and the other will harden like a gasket

I know it sounds crazy. When I called him back today, I told him I got the hi-temp (rtv) silicone 7 he confirmed. I even mentioned that I planned to use a marine grease or anti-seize. He reiterated to use the hi-temp silicone. The link below is what I will be using per Udor.

Wow! I’m sure they know more than I do about that. My mind is officially blown. At least it’ll be easier to keep the key in the slot when you put it together!

Maybe it’s not as strong of a hold as I’m thinking, I just can’t imagine trying to pull that back off once the RTV has set

I am with you! I am still trying to wrap my head around it. I was actually working on it tonight and decided to stop and rethink adding the hi-temp silicone. The key is very snug in the keyway, but he said to silicone that too. Thinking about it, he mentioned to use rubbing alcohol on the shaft before applying the hi-temp silicone so it will stick. I was able to find one video on YouTube and they used silicone as well.

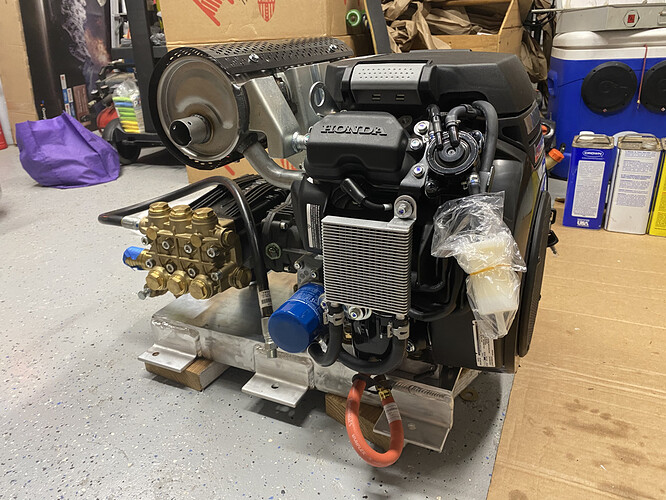

Well, I finally got around to finishing the build. Now, I need to get time to make the stand on the trailer and plumb it up. I hope to get around to building the stand this weekend or next.

Very nice looking machine.

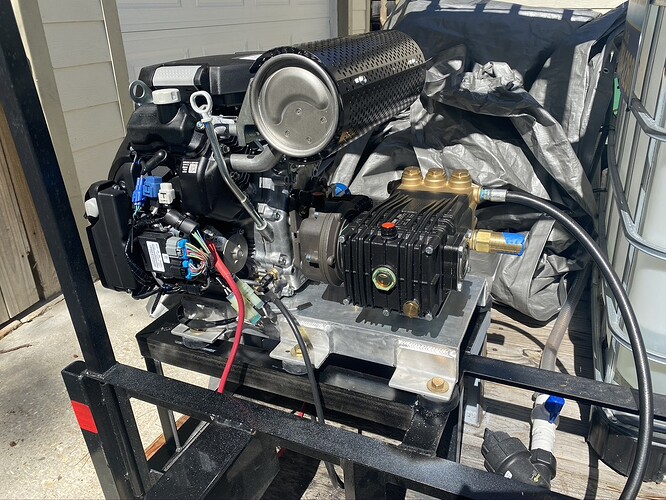

Well, I was finally able to get it mounted this weekend. Now to the plumbing so I can put it to work.

Honda can’t get 690’s into the country. They are sitting in cargo containers in Taiwan. They do have a ton of 800’s here so they are pushing them hard. Way to many issues with them. If you own a 690 you know what a pain it is to charge out the one fuse. Multiply that problem by 7 electrical connections, finding a vendor that has the training and has invested in the software to diagnose them. You can’t bypass the smog sniffer on them. I bought 4 690’s last week to sit in the shop till I need them after my vendor told me about the issues.

Personally, I haven’t heard of many issues from the people I know who run them. But with it being so new, I can understand the growing pains. And it looks like the fuses are a lot easier to get to than the 690, especially a belt drive.

It’s not the fuses, it’s the electrical connections. Fuses don’t blow so much as they corrode. That’s the future of an the connections on the 800. But, I wish you well with it.

I double checked and the fuses are the top two connections to the right & very easy to access. Thanks for the tip on the corrosion. I may apply some grease to help prevent the corroding.

I also just purchased an 8GPM HW machine and anxiously awaiting for it to arrive to plumb.

Easy enough to get to it sitting on a stand. Jam that sucker on a skid with fuel tans and heater on it and you can’t even get your hand in there to touch them. There’s a reason Hydromax goes ahead and drops the fuse wire down for you on their skids, It’d be a royal PITA to get to a bunch of electrical connections on one of theirs.

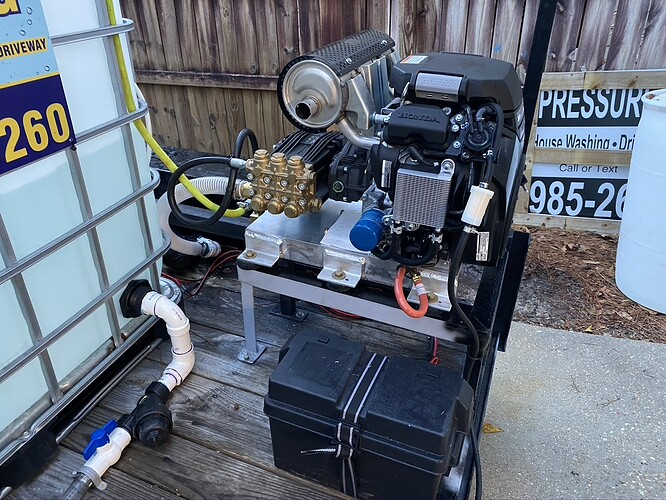

Well, I was able to finally get some time today to get the beast shooting water. All I can say is “WOW”. What a difference from a 4 GPM. Very excited for the next job to put it in use.

Racer, check out my spun fuel tank I had made. It holds 12 gallon and I had them put 2 pick up tubes & in case I add another unit later.

What did that fuel tank run you? I like it

I paid $300 including shipping. I had them install a gauge, 2- 3/8" pick up tubes & vented fuel cap. I got it from BAM Manufacturing out of Kansas. Great people to deal with and it fits perfect on my trailer.

I think that’s pretty fair. Is it fully custom, like did you choose the dimensions etc?