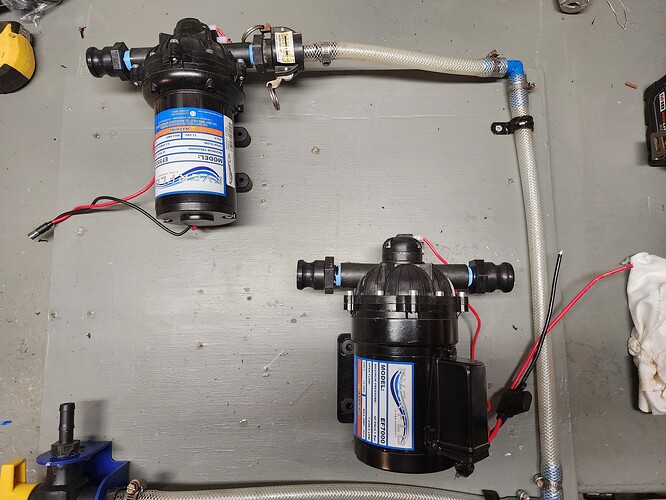

Can I wire these to pumps to the same wire coming from the battery? Add a tail or something from the wires coming from the battery?

Yes, I have mine wired off one from battery, but the wire goes to separate on/off switches.

That’s what i was hoping to do. Did you just wire nut a couple of tails from the main wire or did you put a bus bar in and run from there?

I’ve done 3-4 different ways over the years. Wire nuts will work fine. I use pretty heavy duty wire, think around 12g for my main wire.

Here’s a video I saved because I’m going to rewire some things on my truck build and was looking for ideas on new trailer wiring. This guy is pretty good and may be more than you want to do, but worth watching. Also, if nothing else, get one of the little V gauges to mount somewhere or you can get one built in with switch also.

https://www.amazon.com/gp/product/B07J5Q4912/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

First off, you should run them off a relay, not directly off a switch. Second, no wire nuts ever, those are for solid wire in a house that doesn’t move. Solder and heat shrink is the only way to do it, no butt connectors either. Third, if you plan on running them together in parallel, I’d fuse them individually so if one locks up it won’t kill both of them on a job for you. You should have a fuse right off the battery, within a couple inches, then I’d do individual ones after your relay to them.

Are you going battery-fuse-switch-relay-pump? Or battery-fuse-relay-switch-pump? Are you placing switches before the relay to cut out it’s consumption? Or is it that your battery has so much AH you don’t care about some parasitic drain? I’ve been using very small 12v batteries, so maybe it is an issue for me. Really thinking about using a lifepo and adding a small panel and controller so I can end my battery maintenance cycle (that I often forget to do).

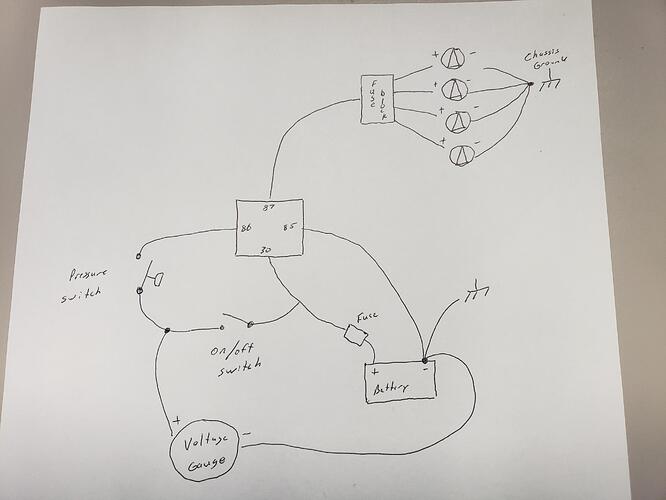

Battery - fuse - relay - on/off switch - pressure switch - back to relay - fused distribution block - pumps

So basically my on/off gives power to the pressure switch, then it back to turn on/off the relay. This is how I’m running all the pumps off one pressure switch and using each pump built-in pressure switch. This way all run perfectly in parallel.

Ooh fancy. That’s really nice.

Way better looking than my wiring lol but mine is full blown KISS so even my jello brain can figure out what’s wrong when it’s 100° outside and I’ve got soap sitting on a wall.

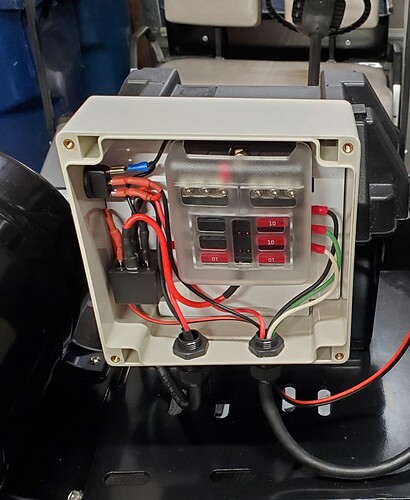

This is all going to get removed and put in a smaller box and I’ll probably add one of those panels that @Racer linked above. I, too, have been watching some boat wiring videos and I’m going to implement quite a few of the things I’ve seen.

My bulletproof setup:

I like having the small lighted switch on the outside so I know when it’s powered on, but those switches can’t take the current, that’s why I run a relay. I also have a digital voltage gauge on the outside of my electrical box as well, but since I switched to lithium that’s useless. Lithium’s output is either full 13.5v or dead.

Ohh that is pretty. I couldn’t get my fingers to do that. I have to have space. I like the setup a lot.

Thanks for posting that, but I can’t figure out what both sets of wires go to outside the box. Is that a remote or a switch or dual feed for your other rig ignition?

I will say one thing, I like the simplicity a lot, it works better for my addled brain and my non dexterous fingers. Plus it is a nozzle holder.

I have a small footprint tote that I keep my rags/bags and backup boots in (and a large pipe wrench that I never want to use), but I am thinking about using one of the aluminum diamond plate boxes. That tote hasn’t leaked in 4 years and sits outside year round, so maybe I should just repurpose it.

The far left is the pump wires going to the solenoid. The near left is running to a LED voltage gauge to keep an eye on the batteries at a glance.

I’m a huge fan of having everything in a plastic box for a couple of reasons:

A) It doesn’t rust. I spray the hinge pins and the metal latch mechanism with a bit of PB Blaster when I do general maintenance on the trailer.

B) God forbid those batteries should ever come loose (I removed the hold down that I use because I snapped that picture as I was hooking up the battery tender and it gets in the way) and start banging around in that box, there’s very little chance the batteries are going to ground the posts out on the plastic box.

C) The plastic doesn’t retain heat like metal boxes do. I run my pumps mounted outside the box for obvious reasons but those batteries and solenoid and electronics in general tend to last longer in a cooler environment.

D) They’re dirt cheap. They’re $99 at Menard’s so I bought a handful of them when I was building the new trailer. Here’s a link for the boxes I use. I carry chemicals in one, 12v setup in another, extra rags, window cleaning equipment, and other general BS in another one. I use one for all of my kayak fishing stuff so I can load up and go in a flash. They’re great little boxes for the money but not exactly much of a theft deterrent as I’ve been able to jimmy the latch open with a screwdriver before when I left my keys at home.

If you have time to educate me, I really couldn’t figure out your setup. Electrical is my weakest knowledge base and 12v is behind that by a way.

So after your inline fuse your hot (+) goes to 30 on the relay, and goes out 87 to your fuse panel? Fuse panel powers pumps and lights? Meanwhile your switch comes off 86 and then directly to your pressure switch? Your ground come out of 85 and is grounded to the battery?

See what I don’t get is if you come off 86 to on/off switch then to pressure switch, how does it regulate the pumps? It would have to control the power to turn them on and off. Unless it backfeeds through the on/off switch and breaks the circuit at the relay to turn power off before the fuse box? I really don’t think I need a pressure switch, I don’t do roofs, and I don’t have 2 12volts, but I do need a 12v education if you are willing to provide it.

Is your fuse panel grounded to your battery or to your frame? If it is grounded to your battery, is your battery grounded to your frame?

12v + from the battery to 30 and also the on/off switch. 87 out to the fuse panel. 85 is ground straight from the battery. 86 is coming from the pressure switch. That on/off switch supplies 12v+ to the pressure switch when turned on.

The pressure switch is a simple normally closed switch. So, when I turn the on/off switch on, that simply puts 12v+ to the pressure switch which is set at 90 psi. So, turn the on/off switch on, 12v+ goes into the pressure switch and out to the relay turning it on and supplying power to the fuse panel. Once it reaches 90 psi, the pressure switch opens and no longer supplies power to the relay, thus turning off the pumps. My voltage gauge gets power off the switch, so it’s on all the time the switch is turned on, not with the relay.

Once I turn the power on, all 4 pumps come on at the same time and build pressure, then they shut off at 90 psi. As soon as I start spraying, the pressure drops below 90 and they kick on again basically instantly. The pumps I use have a built-in pressure switch that is adjustable. I crank them down to the max to render them useless since the pumps can be set to max out at 130 psi.

I have a ground wire from the battery straight into by electrical box that then splits and grounds the fuse panel, relay and switch. I also have the cart grounded as well and my pumps are grounded to the cart. I don’t have a picture at the moment, but I run a ground wire to a bolt going through the cart, then use that bolt as a terminal to run all 4 pump grounds to. So, a wire is direct from the battery to the pumps, but also grounding the whole cart.

Hopefully, that makes sense. Let me know if you have any more questions

Thank you, I think I understand now. Once again, if you are willing to take the time and educate me I would appreciate it. Let me be super clear for anyone else who might be reading this, I am no 12v expert or relay wizard, I’m not trying to “burn” his setup, I’m just some dumb schmuck trying to learn a thing or two from someone who uses 12v pumps.

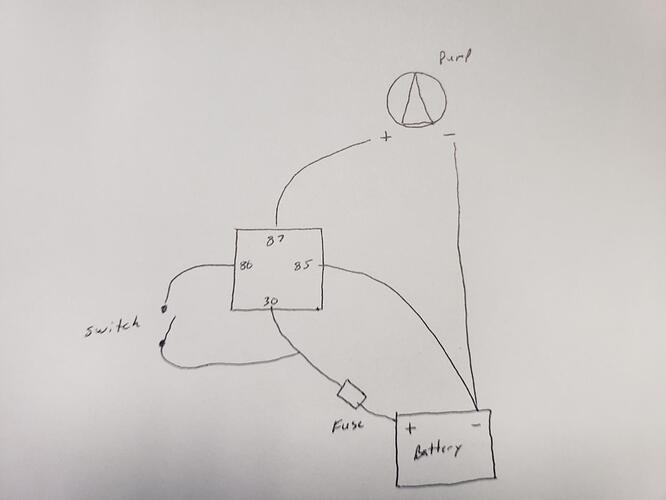

I was told, and saw a video or two, that said battery + - inline fuse - on/off switch - 30 is incorrect, that the switch shouldn’t carry the load - that the relay should carry the load. Look, I want it to be as simple as possible because it is easier for me to understand and hence harder to screw up. But I was told that there is a risk having the straight battery - on off switch -pump and I should add a relay. Your not putting the on off after the relay?

I see your pressure switch coming off relay 86 is the same as these guys are saying, but your on/off is still in line. Does the fuse panel somehow negate the need for the relay to handle the load vs. the switch?

Not going to lie, after watching videos about relays I think if I met the person who numbered relays I would punch them in the face at this point. Makes no sense their numbering scheme. How about in out ground etc. I get that the magnet in the relay opens and closes the circuit (I call it a gate because that is what it reminds me of).

My on/off switch is inline with the battery, but carries no load. It’s just a switch to feed another switch (the pressure switch). You are correct that a switch should never carry a load, so do not do battery - on/off switch - relay 30. Relay 30 is straight from the battery, but after the appropriate size fuse.

Your relay is your pumps on/off switch that is able to carry a heavy load. 86 is just the means to turn the relay on and off, doesn’t matter how it gets its 12v+.

My fuse panel with 4 individual fuses isn’t necessary since I have a main fuse right off the battery. I do this so if one pump locks up, it only blows its own fuse and the other pumps keep running.

For one pump with its own built in pressure switch, this is all you need. Pretty simple. How and where you make the connections is up to you, but basically like this picture shows.

Thank you for both diagrams, it makes more sense now. I might add some purty lights or something later, but I am actually looking at using this more for decks and maybe log homes. Depends. Not planning on adding any roofs, unless they are 1 story. I have to do my own this year, that is the only time I’m using a ladder and doing a roof this year.

Once again thanks. If our paths meet I owe you a beer or coffee or whatever.

I replaced my relays with house light switches and 20 amp push button circuit breakers, no issues last season. I also replaced the solenoids on my old Hanney reels with new momentary switches from amazon and 20 amp breakers. Less wiring and no issues. I also like to use old 10-12 gauge outdoor extension cords and cut them to fit 3 wires and a nice jacket on it. Thicker the better.

Sure, there are plenty of switches than can handle the current of 12v pumps. Personal preference, but I like nice, small, automotive style, lighted switches as opposed to large, heavy feeling breaker types. Plus, a cheap switch and relay is less expensive compared to heavier switches that handle the same current.