So whats everyones Trailer setups look like. Open or Close, Hot or cold. Post a Pic and talk about your likes and dislikes of your trailer. The reason Im asking this winter Im redoing my trailer. I want to make it the last time I do it. I guess be as detailed as you can be. Size of tank, Brakes or no brakes, What hose reels you have and where. Roof pump and extra chem tanks… I’ll get my up Monday. Heading out of town and wanted some good reading while my wife does the driving… BEACH here I come.

18’ flat deck equipment trailer. Rated at 10k with brakes all around. Set up with reels on curbside. Hannah electrics stacked for pressure hoses plus one for roof hose. Hand crank Hannay with 1" internals with Mean Green feed hose hung on side of tote tank plumbed into tank.

Two Group 31 truck batteries tied together for fatboy and reels. A stack of traffic cones on either rear corner for extra visibility and ease of setting up. Ladder rack and little else on street side.

Everything we would ever need, times two, plus spares and extras. 300 gallon tote tank. One 55 for roof mix plus room to slide a 55 of SH on the street side at the supply house. Full water tank every time we leave the shop. 8 gpm cold and 10 gpm hot.

Too big. Too tight in some neighborhoods. Hope to set up 18’ box truck this fall.

Pictures? Probably not. Although it seems to work really well, somehow it always looks ghetto in photos. Who knows, maybe it is.

That looks cool Tim. Not too Ghetto. I like the barn in the background. Wish I had one.

Hey Tim I like that Powerwasher:cool: how’s she holding up? That burner always seemed to heat up pretty fast.

Just like the news, Fast and Furious. And water, man, that thing moves sone water.

That thing is a beast, Tim. I could never get it through the neighborhoods I work in, much less down the lonnng, narrow driveways.

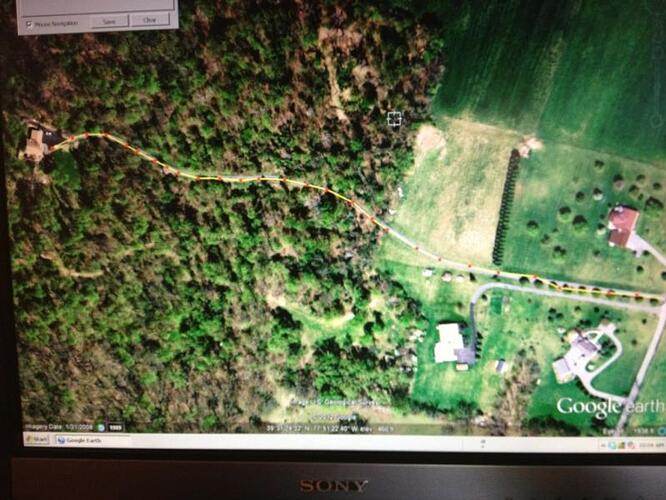

Agreed. I think the record this year was 1,600 feet. Zach was able to turn around in the field out front though so he only had to back it a little over 900 feet. This is the job I had him pack a bicycle on the trailer so when he had to go out front to get the water truck, he didn’t have to walk.

Short route

iPhone - Tapatalk

That was a killer driveway!

I work mostly in golf or lake communities- no fields. They pull their Mercedes or BMW straight into the garage.

Good looking truck you got there.

This is half of our rig below. We have 4 flatbed trucks and 4 trailers. 10 hot water units and 2 cold water units. I need to get a pic with our whole rig at once but 2 to 3 trucks are always out on jobs pressure washing…

Dang. I’m such a small fish in a big pond. I have a used pressure washer and small flat bed trailer. I’ve got some growing to do. Lol

Phil we all start somewhere and grow into what we all like for our companies to be at.

Very true. I’m a window cleaner that uses power washing as an add on. I don’t see us getting that big into power washing. Windows are our priority but that could change if there is better money in power washing.

Power washing certainly can be profitable but I bet that windows need serviced at much closer intervals.

iPhone - Tapatalk

Pressure washing generally commands a much higher gross per man hour but window cleaning is done more frequently and with much lower overhead. A mix of the two can be very profitable.

Thats cool sounds like you have a nice fleet.

I agree and this is where I am right now. I don’t see that changing soon as the calls are 10 to 1, windows over pressure washing. I like the fact that I don’t have thousands of dollars invested in huge pressure washing equip. I like going to work, cashing a check and knowing that most of it is profit. All my equip right now is paid for except my truck and that’s my daily driver too.

http://seatosummit.smugmug.com/Work2012/New-Trailer-2012/23842391_Gqftk9

Alex,

I have been pressure washing for a long time. I started out with an 5x8 open utility trailer that I already just happened to have. Since i did a lot of wood restoration, I carried a lot of deck stripping chemicals and wood working tools that I didn’t want to leave out to the elements so I switched over to an 8 x5 V-nosed trailer.

It wasn’t long before I outgrew that trailer so I bought a 14 x 6 V-nosed enclosed trailer. I put a lot of thought and planning into that trailer and it served me well for six years.

But during those six years, I continued to grow and added more equipment and a couple of years ago I realized I had outgrown even the 14 x 6 trailer. However, even with all the planning and design I had put into the 14 x 6er, I kept seeing, right from the day I put it on the road, ways I could make improvements in my next trailer.

Last year about this time it was clear if I was going to continue to grow, I was going to either need a second trailer, which meant another truck to pull it, or get a bigger trailer.

I went with the bigger trailer. I now have an 18 x 7 V-nosed enclosed trailer with all the design improvements I had come up with during the past six years. I have given you a link you can go to to see the trailer and the building of it, but like I said, it is a V-nosed trailer and that right there will give you an additional 24" inside the trailer essentially making it a 20 footer without making the trailer any longer.

It has tandem axles with brakes on both axles. I have a 225 gallon tank inside that is my buffer tank for two 5.5 Hydrotek skid units.

I built a place to put my two stacked Summit Hose Reels and a cox reel with 200’ of chemical hose for roof cleaning. Underneath the hose reels is storage that will hold six 6 gallon pails so I can easily store 30 gallons of bleach right under the hose reels.

To the left of the hose reels is a water manifold where I can direct water to go to anything I want in the trailer while standing in one place at the rear of the trailer. I can direct water to the buffer tank or I can cut the tank off and send water to either or both machines while bypassing the buffer tank. I can turn water on from there to the DI tank I have on board and I can also turn water on to a water hose for filling buckets etc at my mixing station at the back door.

I have LED lighting inside that is on a 60 minute timer switch so I do not have to worry about forgetting to turn off the lights when I am locking up and the battery that powers them and the 12v Delavan pump is kept charged with a solar panel on top of the trailer.

But with all that, the floor is where I put the most effort. First I drilled holes in the corners and in critical areas where I installed 1 1/4" PV pipes for water drainage. Then the entire floor and 6" up the sides were fiberglassed. Then I coated the floor with epoxy and up the sides for 8". On top of that I coated the epoxy with a clear sealer.

Anyway, check out the link to the pictures to see my rig. When I outgrow this one, I will finally be at the point where I will probably have to go ahead and put on an additional trailer and truck. I am already designing that trailer in my mind right now.