I know brinelling is a thing but my QDs get wrecked in a couple jobs. Is it something with my pressure washer? Its running 7.5GPM at 4000psi. Set from the supplier. Haven’t messed with the unloader. Could the pump be pulsating and damaging the QDs?

mostly, you only have to worry about is the very tip. if those get chewed up by letting your ends drop to the ground or dragging them, will eat away at your orings fast. leaks leaks leaks you could put a new oring, but theyll fail quickly too. is that something your experiencing?

No, it’s not the tips. I never drag them. Its where the female QD ball bearings grip onto the male QD base. It just chews it up and makes removing wands and surface cleaners a PITA

A) those GP SS fittings are not the greatest of quality. They’re not terrible but they aren’t Foster either.

B) what type of unloader do you have? Pressure trapped can and will speed up how quickly QC’s get trashed. No experience will flow actuated unloaders but I assume they probably help alleviate this due to the gradual ramp in pressure vs the immediate spike. Could be wrong though.

C) you need to verify that your unloader is adjusted properly. If it’s spiking any more than 2-300psi over operating pressure when you let off the trigger then you need to dial it down to that range. Ideally, have the gauge that you use to check this installed on the pump manifold. Not down by the gun or after 10ft of whip line. Right on the pump for best accuracy.

If the o-rings in my female fittings have been in a long time it seems to speed up this type of wear. I bought a big bag and change them out periodically now. It’s almost as tho with a worn o-ring the fitting gets a running start to bottom out, so if your qc’s go together really easy might want to look into replacing o-rings in the female side

You can probably dial that unloader back just a smidge. I like to see about 300psi spike above operating. @CHogue brings up a good point as well. O-rings degrade (like everything else in this racket) and allow for more wiggle room. I recommend using premium O-rings on everything. The standard black ones are terrible.

Question for you. With that spike pressure, I am wondering how much your unloader is bypassing while you’re on the trigger. Do you have a small trickle bypassing or none at all?

I’ll check the unloaded and bypass later. I get black viton o-rings from the pressure washer equipment store at $1 a pop. I bought this viton oring set from Harbor Freight but haven’t used them yet because I assume they’re not good, I just have them in case I forget to buy more from the store.

I carry one of those kits on the trailer, too. Handy to have but you can usually find bulk viton O-rings online in the common sizes we use.

Thanks. Where do you order yours from?

Also unrelated but what happened here? Was greasing the SC but it kept going. Never reached the nipple. Look under and find this

I’ve never greased my surface cleaner. Some guys say you’ll start having issues after greasing them. I’ve never had issues with mine but I do carry a spare swivel for it. I get my O-rings from pressuretek

No water is coming through bypass when trigger pulled, not a drop. Measured only 7.5gpm on a 8gpm pump. Psi is 4100 operating.

Turned the unloader counterclockwise a smidge from 1 to 2 as marked. No change

Do you have the 0° tip that came with the machine? If so, click it onto the gun. Start the machine and squeeze the trigger while watching the bypass hose outlet into the tank. Adjust the unloader until there is a small trickle coming out of the bypass. That’s the correct process for adjusting virtually any pressure trapped unloaders. Once it’s set, you don’t adjust it again. When it fails, replace it and follow the same process.

It will typically take considerably more adjustment than you moved it to see any change in bypass flow.

No. Would a turbo tip work? Or 15 degree tip? I moved it more. Basically one 360 degree full turn to the left and zero change.

I’d probably use the 15°. Yep, sounds like you can keep backing it off. What is your gauge saying now?

Went to gas up the rig for a breezeway job tomorrow. On startup to test again I got very low pressure for about a minute or two. Eventually it came up to normal pressure again. Maybe the hose drained out a bit for the 30 minutes between tests. Prior to this I set the unloader back to where it was initially. Gave me a heart attack that my unloader went out. It’s fine right? I’m just gonna leave it where it is for now.

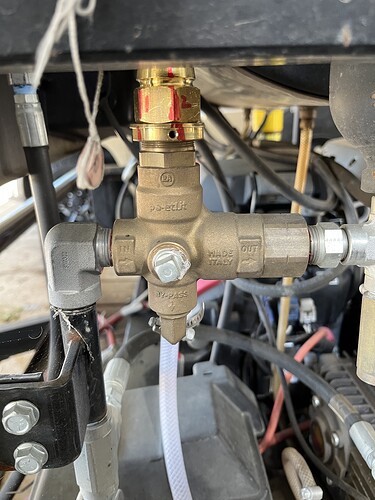

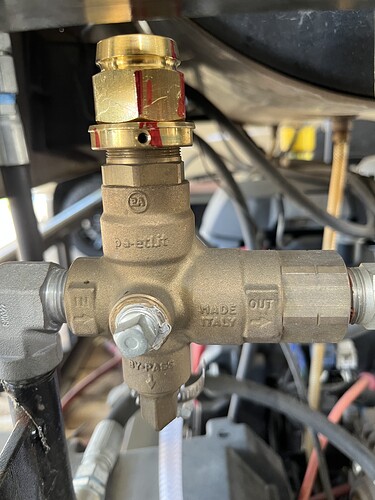

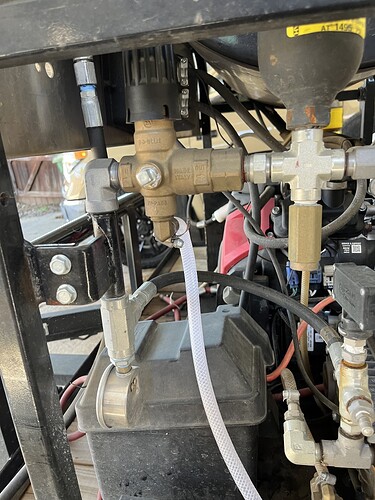

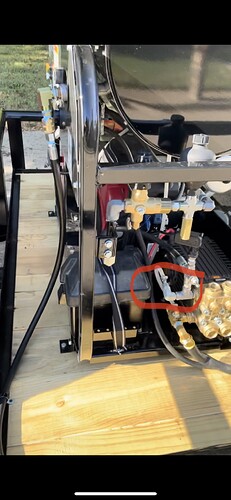

I’ve been looking into getting a K7.3 unloader. My current unloader setup is a bit complicated though with some nitrogen tank the seller put on it. Is it basically plug and play with unloaders? Haven’t had to mess with it yet.

It’s probably fine. If it works for you, just leave it. If you’ve been running that machine with zero water bypassing I’m honestly surprised you haven’t had issues with it this far.

As far as flow actuated unloaders go, I am not the guy to ask. Never had one and don’t really have any plans to switch.

What kind of issues would you expect? I figure if I’m losing .5GPM that it would be bypassing to make up for the greater PSI. Was hoping to get it to 3500 and 8gpm again.

If you want 8/3500 you can adjust the unloader as described above until you achieve a small trickle coming from the bypass hose and the pressure is roughly 3500psi when on the trigger.

I would have expected to wear out a couple unloaders in a short amount of time. If the unloader is set too high pressure may not bypass when you let off the trigger. Usually the pressure will build quickly and the unloader will eventually be overcome and click into bypass mode before anything catastrophic happens. If it never bypasses, the pump goes boom.