I have the patriot proportioner I put together myself. It doesn’t pull more than a weak stream of water now. I did nothing but clean out the truck and move the pump and proportioner a little lower in the truck bed. The only thing that works now is if I put a short piece of hose (no proportioner) on the intake and pull from a bucket. I found a cracked check valve and took it out of the equation. I took everything apart and checked for leaks using a bucket of water. Blowing bubbles all day. Filling up buckets of water to test again & again. I’m ready to shoot myself. It 's been 2 days str8 working to find out the problem.

You know the answer. Got an air leak somewhere, just have to keep eliminating the good ones

We should just make it so threads close once Racer answers…but yep, something is cracked somewhere. Spare parts on hand for all those pieces.

I have it set up w/banjos. I got rid of the cracked chck valve but still same story. Here I’m bypassing the hose reel.

if you’re getting bubbles, 99% chance it’s on the intake side. Shut off your valves and check suction on each one with the other 2 closed. total time to determine should be about 15-30min. Same as when you prime it for the first time. It’s literally a 1-2 min deal. I re-prime mine anytime I haven’t used for awhile.

I think I came up with 14 leak points that you could get on that design! Ever thought of running a manifold block so you could eliminate plenty of the possible leak points?

I’d ditch the pentair valves…they’re notorious for hairline cracks. So definitely check them, I used them once and they didn’t last long…threw them out and went with a beefier metering valve, have had no problems in years. A solid manifold block would help too.

I fixed mine (Pentair) with marine epoxy last year after building it and sealed it up good. I think I had 5 leaks. I have seen past threads with people designing solid manifold blocks but have never seen for purchase. Any sources to research it out??

Oh man, what a nightmare those pentair valves are. I chased air leaks forever with those stupid things.

Part of the problem is the Teflon tape, you’ll need plumbers putty to even think about chasing down a leak somewhere. Soon as you can get rid of those and get one of these.

I took the whole thing apart but don’t see any visible cracks

I probably do need to upgrade those valves

I’m tellin’ ya, it’s not a crack issue. That Teflon tape won’t seal air leaks very well. I had to practically weld everything together with putty before it would draw decently.

How do you have it mounted?

I have the cross on the bottom

Ok I had to go look at my proportioner.

Mine is janky, but I do have the check valves ABOVE the metering valve. Not sure if that makes a difference.

Those check valves can break a spring really easily, causing all kind of havoc. I did notice the one on the left doesn’t have a check valve.

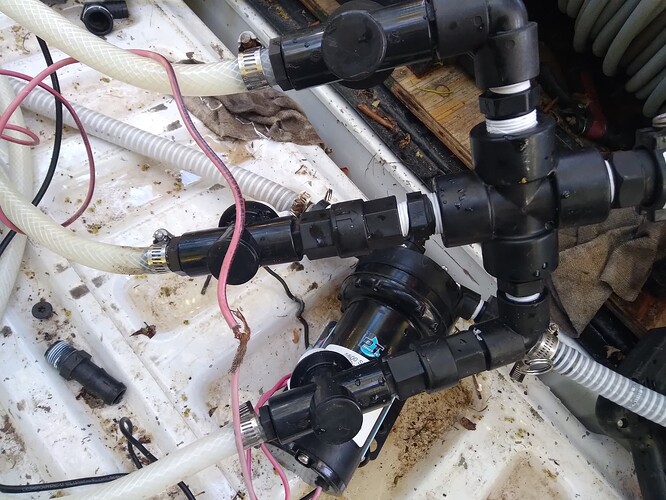

I meant more like in terms of stability and protected, not orientation. ![]()

It’s wired to a piece of metal which kind of just floats in between the battery & buffer tank.

I should mention that it was the same as before except I oriented it lower than it was before. Same w/the pump.

I ended up taking mine apart and using both tape (which is a lubricant not a sealer) and thread sealant. I have a Midwest Proportioner - I believe they sell the manifold blocks separately if I’m not mistaken.

I went ahead and put everything back together like I know nothing about it; then I opened up all the valves and ran the system; closing them one at a time etc. It looks like I got it & the system was just airlocked. When I was running all of the tests before, I only used the water intake, leaving the other two closed because I didn’t want to spray any chemical or soap in the yard. From now on I bleed the entire system after not using for awhile.

Téflon tape not a sealer??

Interesting.

Teflon tape is a friction reducer. It helps mating surfaces together easier