You’re right it does help. The difference is you’re setting your thermostat to 85 and he’s setting his to 125 or so. I’m guessing at the number based of his comment about barely above 100 when it hits the siding.

A ball valve is one of about 6 pieces of an injector bypass. I’m now thinking you are thinking an injector bypass is something else. Either way, I only try to comment on your post to keep others from getting bad info. It would definitely be better for all of you quit posting and just read some more, but it’s a free, open forum, so carry on.

Xjet is a high pressure nozzle

And a ball valve is IBS’s paper weight on his desk. I also get why. It can be dangerous if the wrong ppl use it, Like employees for instance.

You use a ball valve on both the end of your line and on the bypass. The bypass works by turning a ball valve on or off to bypass the water from going thru the incredibly small hole that it must pass thru in the injector. If your running an 8gpm machine and forcing a 3/8” line of water thru a 1/16” hole the entire time you are sacrificing flow. Here is a pic of my bypass, which is basically a ball valve with a 3/8” hose and fittings. Are we talking about different things here?

Do you see all them 90 degree turns man ?

The 90’s reduce flow more than a 1/16” hole?

Edit: if you tried to breathe thru those 90’s with a 3/8” line you could. Try and breath thru a 1/16” hole and which do you think would be easier?

Yes. Simple friction loss.

Can’t you put the DS in the loop if your hell bent on keeping the bypass. then you got less 90’s

Thinking ain’t cha @Seandz ?

Stupid analogy. It doesn’t bother me that you use a bypass. That’s only hurting you. Like I said, I only care when you give bad advice that could hurt others. And a ball valve is not a bypass lol. Supper is almost here. At mellow mushroom but they sell burgers so life is ok.

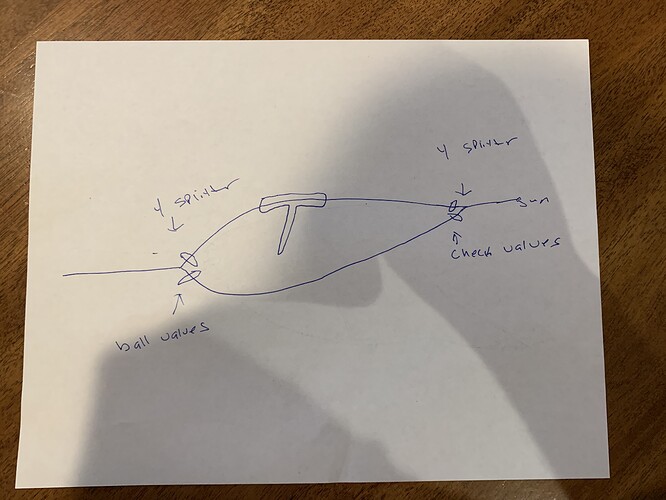

That’s a good way to help. I don’t see much difference with or without a bypass on. I do save time not constantly taking the injector on and off all day. What about making a Y splitter on each side? Might be expensive and have 2 ball valves one on each inlet side and 2 check valves on exit side that goes to the hose. That way you only have two 45’s.

Why wouldn’t you just put a shut off on your soap line. If you are not seeing a difference with or without the bypass then you dont need to take the injector on and off @Seandz

I mean bypass installed or not . The argument is that a bypass hurts flow period.

Why would you take the injector on and off

I know this . My burners consists of 200’ of sch 80 pipe. its built in circles not squares . Just saying.

On a lil derailment, where is the closest MVP shop to Jacksonville NC @Innocentbystander ?

MVP shop??

Ibs is saying he doesn’t use a bypass because he loses flow with it. If he is washing a house he needs his injector. I’m assuming that he removes it when he wants to rinse or use a surface cleaner, how else would he improve flow aside from taking it off, which requires turning the machine off and restarting, or a ball valve before the injector to temporarily turn off the water to remove it. @Innocentbystander can you post a pic of your setup to enlighten me?

I don’t use bypasses but if I did, this is the way to go. It’s too easy for me to disconnect the injector for flatwork.