Is that a bruise the heel comment lol

Just make sure you leave enough of a lip. Take two passes on the lower end.

I’ve never had a dremel that works for longer than 6 months. That’s just what I call them because that’s what most people have.

I have a Black & Decker I picked up at target for $15-20 after Christmas 2 years ago and I used it constantly and a couple of the cheapest harbor freight ones you can buy with cutoff wheels at the ready.

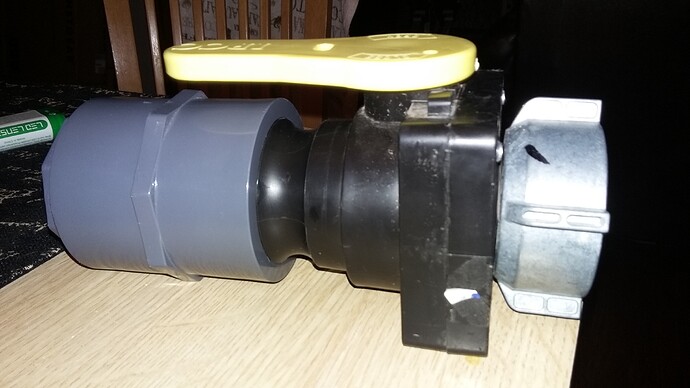

I have two of these on my rig…one takes a 2 inch threaded female adapter and the other that looks like your threads I have to use a cam lock

I’d try what you have. I know guys that just slide them together. Not a lot of pressure, long as you have tightened, it should work.

Those valves are set up to connect to a 2 in banjo coupler https://www.agrimart.net/2-female-quick-coupler-x-2-male-thread-200b?gclid=CjwKCAjwypjVBRANEiwAJAxlIkn_R3Ks6wbUaBls8oNBhwGe5F6Q3UqWlP8Iggx_eCw-PKCwSv3MpxoChrwQAvD_BwE

They work really well and it makes it easy to disconnect if you need to pull the tank. That 2 in valve won’t restrict the flow anywhere near enough for it to matter

I just like doing things the hard way apparently.

If going with couplers on plumbing, how much will they restrict flow vs regular fittings?

It won’t on a 2 in. Should still get close to 20gpm flow out of it. I get 11ish gpm out of each 1in feed line

Thanks for all the quality info gentlemen. Warning: more plumbing questions to come

Ya that’s what I use. $12 at tractor supply

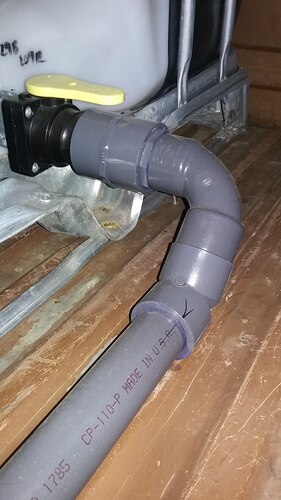

I would suggest not to use "T"s but rather curved pipe.

That’s good info on the poly braid, which is of course what I used when I plumbed my 8 GPM machine. Guess I’m lucky it doesn’t get hot here in Texas…Oh well, I haven’t bought anything new for the business since this morning on the way to a staining job. Good gouge though, EPDM it is.

I have that same 2" camlock nipple/MPT end on my ball valve. The only difference would be that it’s a ball valve and not a butterfly valve like yours but it’s the same every other way. I used teflon tape and a 2" PVC adapter (SxFPT) and then bushed it down to 1-1/2" for the run.

LMAO at it doesn’t get hot here in Texas. Feel free you come wash some tractors with us in a few months. You sir would die!

Any chance of uploading/linking that video you took screenshots of? Looks quite informative.