The plugs you were having issues with were soft steel. Trade them out to 304 SS

I don’t run trapped pressure unloaders but I feel they should last you longer than a flow actuated unloader. I was getting at least 5-6 months out of mine. They cycled 16 hours a day 6 days a week

Can confirm. They’re 2-3x the cost of brass ones, but I have had the same SS set on my hoses and guns for about 2.5 years now. They outlasted atleast one gun and I think 2 hoses. I just transfer them to the next. Lol.

Stainless is the only way to go in my opinion. Ive had some sockets that were duds due to incorrect tolerances creating a drip. But the good ones last a really long time. My favorite part about them is how easy they are to disconect

Have you tried the KZ1 ? they work from 2.5 gpm to 10 gpm up 3650 psi. Which should be more than enough pressure.

The ZK1 is their latest flow actuated unloader and I had high hopes for it. It comes on way faster than the ZK5. I like a slower ramp up so I never ran them to endurance test them. It doesn’t kick by any means but again it comes on QUICK!! The ZK5 holds about 75psi in line pressure and the ZK1 holds much more and I could not whip my hose without the unloader cycling. Doing this put me in the next mode when I wasn’t ready for the change over. My machines were setup to soap then go into rinse by releasing and re-engaging the trigger so they didn’t work for us. Try one out and check it out though

I use one love it.

Mail it to me when it dies will ya ![]()

sure!

How difficult is it to set up a machine to do this? Fleet washing only 1-2 times/week using ds, and would like to eliminate brushing forever if not longer.

Easy enough if I purpose built the machine for you but a pretty tall task to walk someone through it. You’re going to brush fleet at some point or another. We brushed here and there and two steppers need to brush too just not as often so don’t let anyone fool you. Join the FB Group Fleet Wash Done Right for more info

Thanks

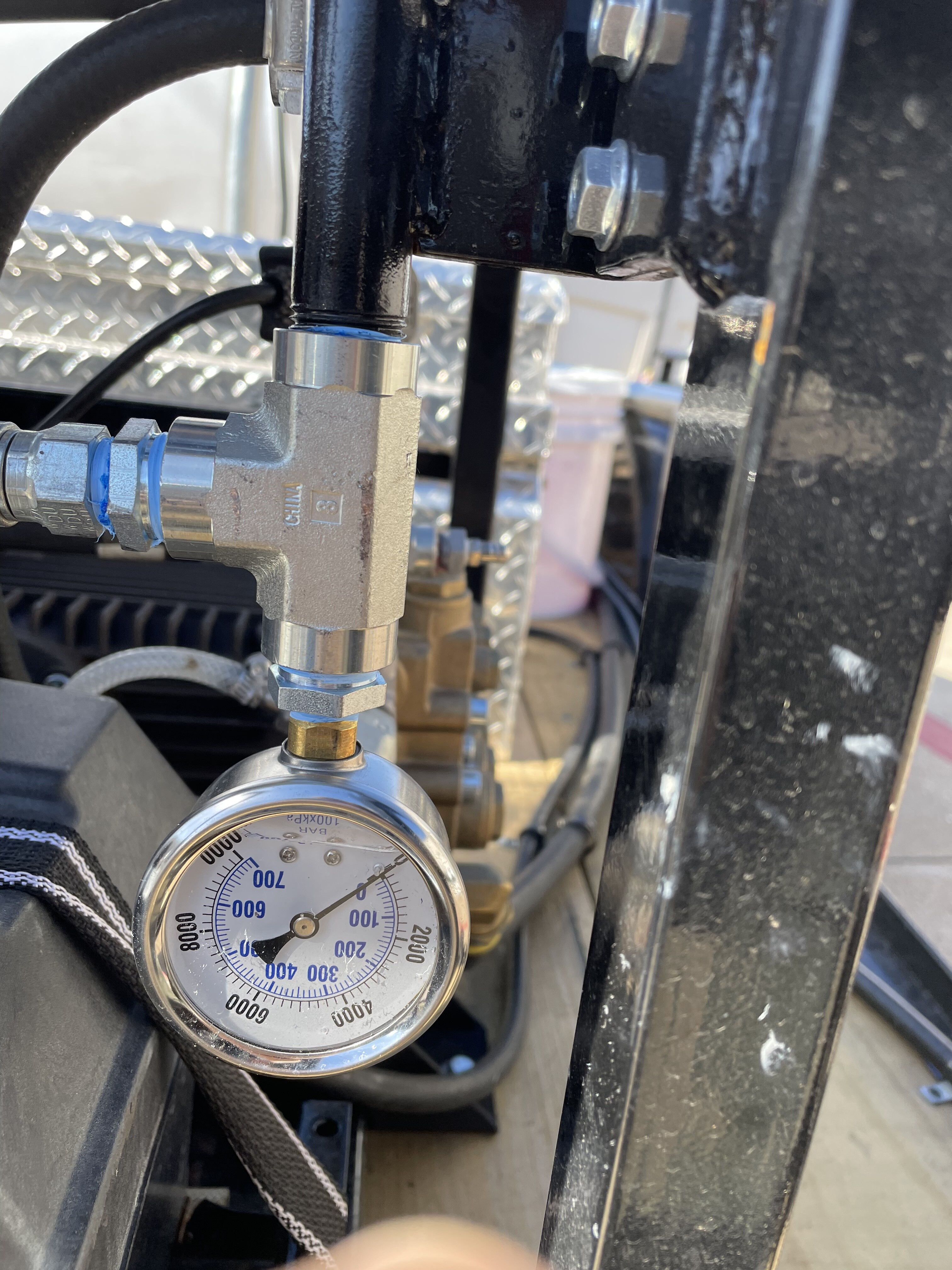

Turned out that downstream injector they installed broke inside and that was reducing the psi. They also said the belt had some slack despite being under 30 hours of use. Some other machines have had that issue. They fixed it and added an 10,000psi pressure gauge for the trouble.

I bought some plugs from them that should be hardened ss but they seem narrow.

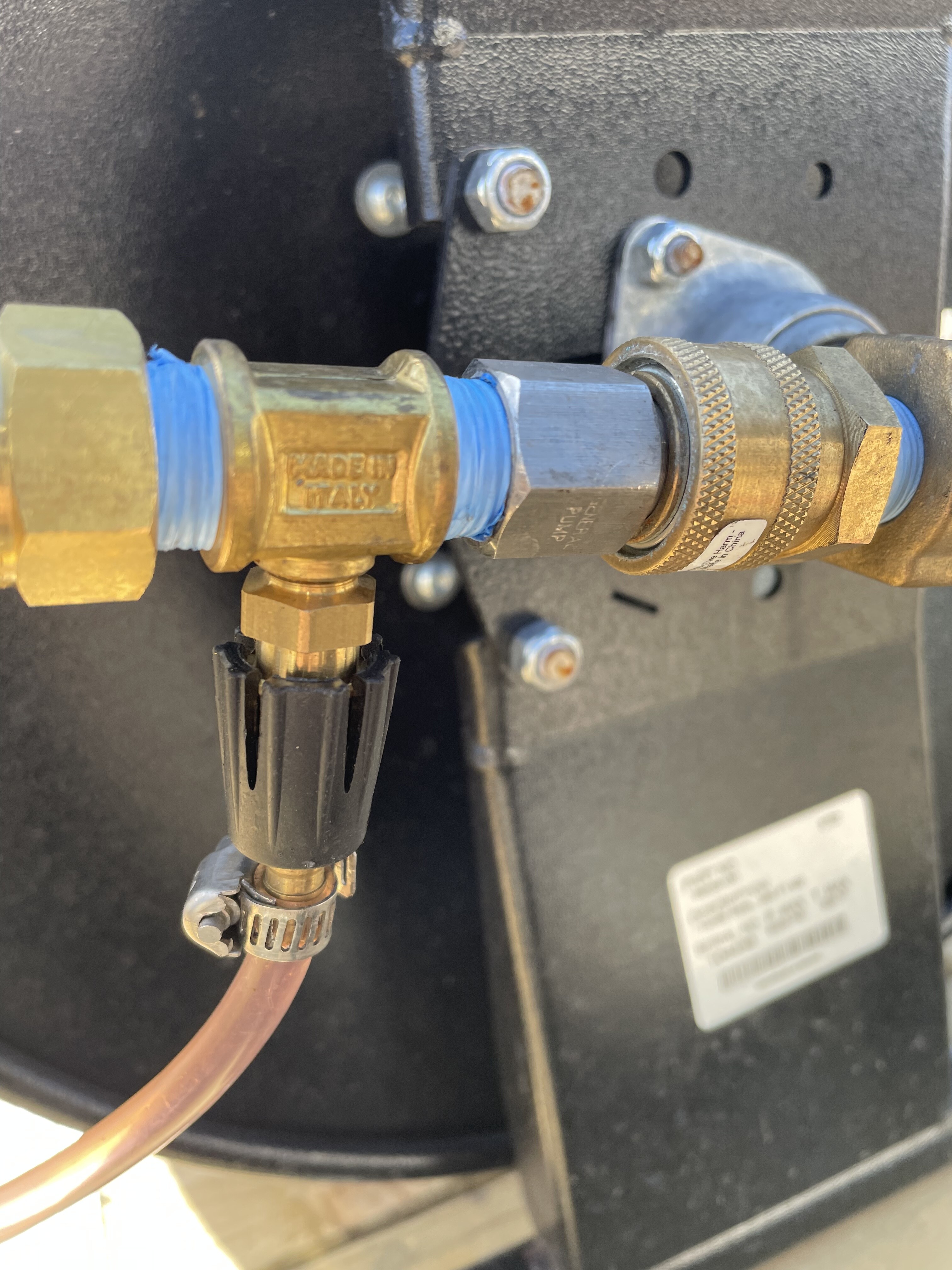

Take the clamp off the D’s hose. And you would be better served to get a good injector.

Any recommendations for the DS injector?

Yeah I know a guy that makes his own! Something about being the World’s first TRUE downstream injector blah blah blah.

I’d love to buy one of these from you! Keep us in the loop. By the way doesn’t he look like @DisplacedTexan 's grand son?

Oh you better believe you’re going to know about it! And in 5 years it’s all everyone is going to use ![]() Yes, I’ve been thinking the same thing ever since he changed it

Yes, I’ve been thinking the same thing ever since he changed it

GP 2.1 injector……