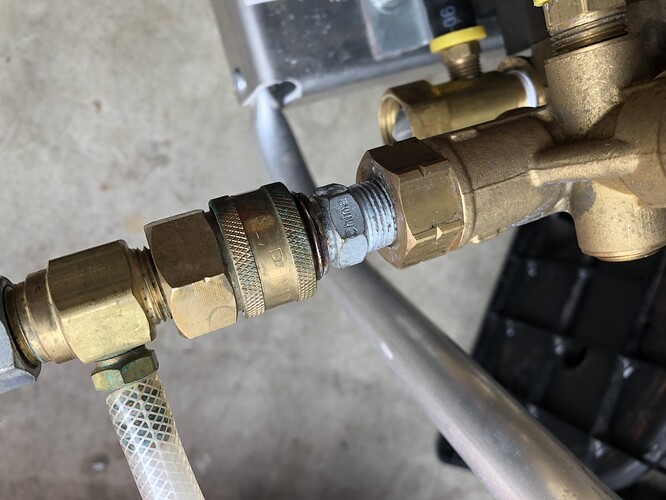

Have a job this morning and just tried to connect my downstream QC and it’s not going on. Appears to be some editing so maybe that’s why? Pics attached. I have another DS so I can use that if needed but curious if I’m doing something stupid that causes this, like maybe I’m not supposed to unhook the DS injector? I’ve only used it like 10 times. Do I maybe need to brush some rust off the inside? Newbie Grasping for straws here so I’ll probably just use the other new DS injector but curious what I did or am doing wrong

Maybe I just need to stop being a wuss and force it on there? but I’m scared to break something by forcing it

UPDATE: I got it on but now it won’t lock into place. Is this usable for one quick job or will it leak/not stay on enough?

It’ll blow right off as soon as you turn on your machine. Just put a new qc on. If you don’t have one and have to get it on you can force it with a tool and it will be fine.

If it won’t lock on, it won’t stay on and you’ll be shooting water all over your rig an possibly shoot pieces of equipment off as projectiles. Replace the QCs and diagnose the problem later - you have spares right?

Take a pair of channel locks and give it a twist it will lock down. When you finish washing today. Take all those brass quick connects off and put stainless steel ones on.

Grease it

As mentioned above qc fail on a regular basis and ds injectors even more so. This is a wake up call for you. Listen to it. Also putting a failing qc on can lock in place. Dispose of it before that happens.

Agree, ditch the soft brass hardware and get stainless. Shooting the fittings with silicone spray every so often will also help.

This buildup is one reason why. I would recommend either cleaning it with a wire brush or replacing it.

I’ve had this problem before and in my case it was always the o-rings inside the female QC. I switched over to SS QC from the advice of many above and it makes life so much easier! Go to the nearest Harbor Freight and buy a few packs of the Viton o-rings to keep on hand. And always always rinse and clean your connections after you get done for the day.

Ask the QC nicely

Yes, viton for sure. Those black rubber o-rings degrade quickly.

It did just that, haha. Blew right off. I forced it on with a tool and it “closed” like it should, but water sprayed out of it, so I believe that QC was just shot. Had a backup QC which I added to it and was good to go.

I did have a spare and it saved me. I knew having spares was important before, but this was the first time I actually needed one, so Ill be even more careful to have backups for everything.

She’s in the trash now

If it’s leaking replace the o-ring. Although, you need to switch to stainless as suggested above.

I need to order me some more QC too but grab you atleast 5 of each types of 3/8 and 1/4 inch stainless steal QC and put them in your tool box. Dont forget to order spare viton orings for each size QC. It will save you alot of headache down the road.

I also use hanson QC on the ones im constantly useing like on the end of my ball valve and tio of my gun.

Do you think this is about the best price I can find? If you know of cheaper and/or better quality, please share a link to where you get yours: https://www.powerwash.com/pressure-washer-quick-coupler-stainless-steel-female-socket-1-4.html

I got a bunch from envirospec when the had a sell on them. Most people are all about the same price range.

Check these sites and see

Pressurewashingproducts.com

Im trying to find the best prices too. Im at work right now and dont have time. Let me know what you find

You find some cheap ones?