Definitely could be some bad luck getting 2 in a row being faulty. But I will go ahead and check for any holes in the lines. Thanks

Be sure the check that the nipple is a snug fit to the tube.

@Sasquatch mentioned to check for the little arrow on the injector, it is hard to tell from your close up of the injector which way your water flows but the arrow on your injector should be pointing away from the pump.

Yep. That arrow is facing towards the black hose reel in the original pic up top which is the direction of the water flow away from the pump

Buy a couple of Bobs Hi Draw injectors and call it a day…

I’ve got a 5.5 and I had the same issue. I ended up throwing 1.8mm I had when I was using a 2.8 gpm machine and it works.

Just received 2 lol starts pulling soap than shuts off right away. Only pulls soap as soon as I start the machine.

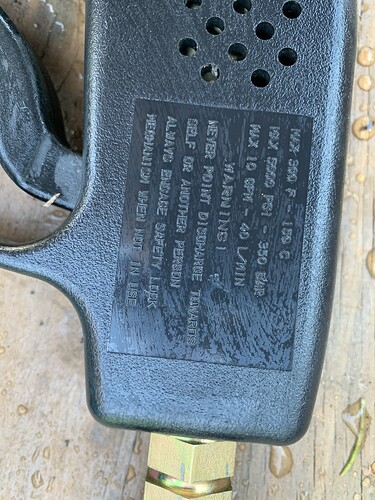

What are you using for a gun? If there’s restriction there, it might let it pull until the line pressurizes fully, and then causes too much back pressure once everything is full.

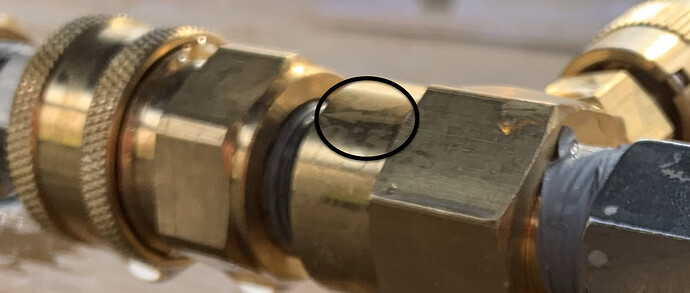

Could be an air leak in the soap path too.

Just the gun that came with the machine and you might be right because my pump is pulsing when I’m not on the trigger.

Will do lmao. Thanks

BINGO!! No more calls please, we have a winner.

Unless you have a clamp on the hose at the intake you will always risk the PRESSURE WASHER taking the path of least resistance and sucking air instead of liquid.

Hey I know I’m low on read time but I really have done a lot of research before signing up. I Literally remember a redditor suggesting to make an account first thing and I ignored it. I also have 2.5 years experience hood cleaning but I have never done soft washing. Happy to report I bought my first personal machine and quit my very cushy management roll yesterday and am going solo! Anyway, I did my first test job on a friends house and I was only able to pull chemical while on low pressure. I’m embarrassed to say it took me over an hour to realize I was only pulling on low. My question is, is this because I was using a white tip and not a jrod? I’m trying to start as lean as possible so I was waiting until I had a two story home to clean before getting one. I was also thinking that it could be because I was using my variable or lance instead of just the pistol?

Sorry this was so long.

Injectors only pull on low pressure, what you have works how it should. Pull injector line out of your soap source and rinse with whatever tip you see fit. There’s too much to explain to you in one post. Ring ex employer and ask for some part time hours until you have a grasp on the basics. Your going into this business backwards.

Now hold on MMH @MuscleMyHustle , he has 2.5 years of hood cleaning, and thats a niche market for sure. It’s not easy learning everything without experience, and the only way I know how is to work, report here, and ask questions.

My favorite way to apply SH to a 2 story house is with the X-Jet for Downstreaming. It’s a low pressure variable nozzle so you can fan lower and stream up high where you need to shoot without skipping a beat. Now some of the wisdom around here doesn’t approve of my method of stopping the Chems, but I just add pressure by switching out to a high pressure tip, spray the next 10-12 seconds of scheme remaining in the hose on the next eave, and then rinse. The pressure stops the DSI from pulling, and to start pulling again I just switch nozzles again.

BTW, my advice is slightly different than my brother’s: develop more flow hood business and the pick up jobs along the way that’ll give you the experience.

I know it’s an extra trip to the truck, but I like using a poly ball valve in the injector tube to stop the injector from pulling. That way I can use any tip I want.

I’m a huge believer in soaking up theory based knowledge before physically giving it a go, that way it’s not an experiment on someone else’s property. They say you have to start somewhere and I agree, start with learning fundamental knowledge of industry basics, the rest is labour.

Honestly I am going into the business backwards, but it’s by design. I have a vision to have my trucks earning 24 hours a day. I know kec as well as anybody but I need to learn soft washing. I already know roof clean ups and pressure washing. I’m spending my first two months selling accounts and learning soft washing.

You’ll be happy to know I was very professional when exiting my previous company and gave them nearly two months notice. I was offered partnership or a decent raise to stay. They even promised me a job if I need to come back. I even managed to lock in some sub work for them in the area I’m going.

I can’t promise I won’t ask some dumb questions moving forward but I can promise to put the answers into action. I appreciate everything you guys have answered already in the past. I have already learned so much from this site.

Can you tell us more about that? You thinking about doing residential during the day and hoods at night? Cross-trained crews?