@Steve at least someone is paying attention.

Hahaha

@Washall Zachary, it is believed that you have neglected the first rule of any forum, and shown no intelligence or remorse towards the fundamentals of reading and paying attention. I summons you to 24 days of “read time” in the rubber scrubbers threads.

@Racer Yo Rick, I have the 3rd most popular thread of all time. And I never even made any money pressure washing anything. I feel half famous. ![]()

![]()

![]()

![]()

I’ve read just about the entire post thank you. I asked mr breezy to contact me. Not for your smart comment.

Second note I stoped reading just before the part where it talks about mr breezes life challenges.

Hey Breezy, I hope that you’re still getting notifications… I know that you’re no longer interested in this subject and I’m sorry, too, that it didn’t lead to more; it sure had potential! Anyway, if you don’t mind sharing your calculation sheet(s) it will be very much appreciated.

I hope it isn’t too much to ask…

Calculations for what?

See post 145

Just type a couple words.

https://washingequip.com/shop/ols/products/soft-wash-hydro-mixer-premium/v/SWHM-V4-ST34

Looks like these guys are selling proportioners with the 3/4" metering valves and outlets, and a 1-piece manifold for $700 if anyone is still interested. I think I’m going to order a few and will try to remember to let you know how they work. I’m running 7 GPM 12 volt pumps.

Those are some huge valves ;>)

You can never have too much flow

You can never have too much flow

Somebody please write down the conclusion here! I’m 1/3 deep in this reading and i just hope im not wasting my time.

So I have an idea to help increase flow, which I would hope would make pumps last longer and also increase stream reach; while keeping costs down. So I agree that the standard 1/2 portioners restrict a decent amount of flow to the pump. Others have basically put a non metering valve on the water line which gets the flow and reach, but the water now flows at a different rate vs the sh so you no longer get an accurate mix and you cannot get a hotter mix safely. So my idea is basically adding a T near one of the 90 deg elbows so now you have a metering system with 2 water inlets, 1 sh, and 1 surfactant. So with both water valves fully open and sh open, if using a 12.5%sh, you should have just about a 3% mix at the gun. So now you should have incredible flow, but still are able to meter the water and have an accurate mix. All the while keeping costs relatively low as these are 1/2" portioners not the expensive 3/4". Before I go through building this, has anyone else tried it or are able to point out glaring errors in the idea? Obviously I’d run a few tests measuring each valves output individually and the 2 waters at the same time.

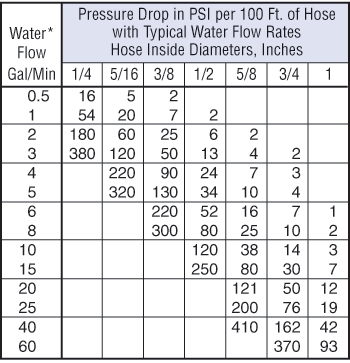

Stick with 3/4” or 1” for all plumbing and metering. Friction loss and fluid dynamics are the driving factors for why. For hose use 5/8” minimum for soft wash hoses. For 12V use 10awg wire.

The chart below shows friction loss for hoses. A 1/2 hose over 100ft loses 60psi for a 7GPM pump if you’re using a 60psi pump you’re maxed out. But a 5/8” hose is 20psi loss. Now most use a 200ft hose which is 120psi lost or 40.

I recommend a 7GPM 100PSI Delavan or Remco pump. Flush excessively when done using SH. For about 5 minutes.

Awesome thank you for all the info Heath!