That is correct.

ok, so are $715 & $915 accurate for the systems you have put together?

Read this. And shipping is about $15 also. The system fits perfectly into a flatrate box.

@getherdone was supposed to get his yesterday, maybe he can give some feedback.

So I learned something new today. In talking to Chemline, I picked up on the rep’s accidental wording and learned that Chemline doesn’t manufacture the valves, they are a distributor of sorts for another company that actually makes the valves, and Chemline rebrands them.

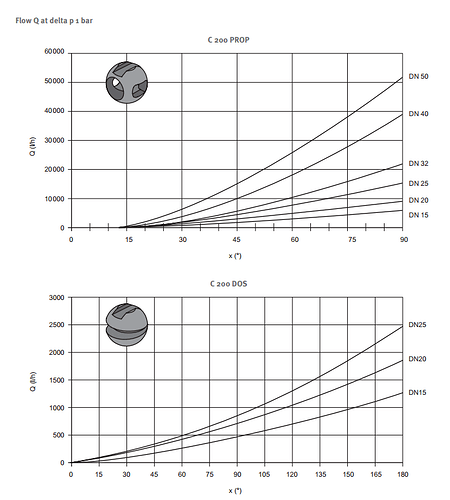

I looked into the manufacture and found more detailed info on the metering valves, but also learned some more potentially helpful info. They also have a linear proportional ball valve. It has 90 degree of adjustment, scaled, but has MUCH higher flow rates. I don’t know the actual conversions for these factors, but I’ve uploaded a screenshot. DN20 = 3/4" and DN25 = 1", so take a look. with a DN20 v-groove ball (metering ball) you get a flow rate of ~2000 units. With a DN20 proportional ball (opens 90 degrees, has linear curve), you get ~10,000 units of flow rate. It’s basically 5x the flow, and that’s in a 3/4" valve. It looks like a 1/2" proportional ball is going to have around 7,000 units of flow, and the 1" is going to have around 15,000 units of flow. So this could allow valves to go down to 3/4" in size and drastically increase potential flow volume and eliminate restrictions and wear on diaphragm pumps.

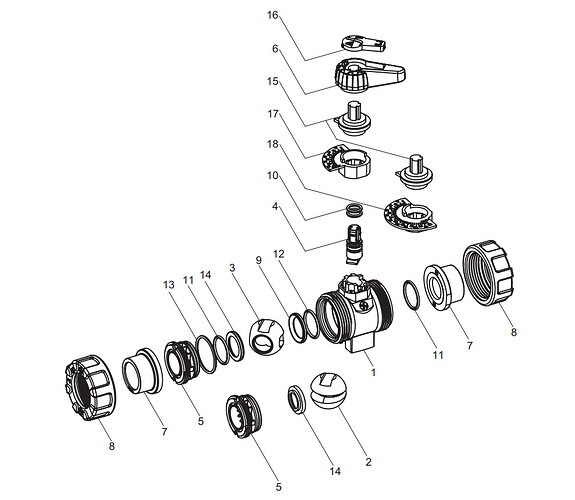

It’s possible that this could be sold with the scale and ball alone as a retrofit, as the valves are able to be disassembled and put back together. I’m going to be inquiring about pricing options. Plastomatic has a similar product but it is astronomically priced and eliminates itself from being a realistic option.

Also, if I can go directly through the manufacturer, I might be able to get pricing down further, but I’m not certain about any of these things. It was a surprise to me to come across this and I am very excited about the possibilities here. This would take nearly all the strain off the pumps.

*Edit: After looking more closely, I think “flow units” are actually LITERS PER HOUR.

So if things work out price wise. we can strictly stay with 3/4" 90 degree of adjustment linear proportional ball valves with 10,000units of flow potentially?

is this them or something similar?http://www.chemline.com/pdf/datapagepdf/SPSeries.MeteringBallValve.pdf

I think if it works out, then yes, it could be reduced to 3/4" and 90 degrees of adjustment. That link is to their old design. That design has been phased out. No longer an option. The new valve body is much nicer, but more expensive as well.

what is the price for those type 3/4" valves

You missed it. ![]()

I got excited lol

It does look like things could be ordered individually maybe as spare parts. I’ll update when I find out if retrofit is an option, or only new valves as a whole, and if it’s even reasonably enough priced to consider as an option.

In this screenshot, you can see the two different scales and also the two different ball designs available.

C’mon! It’s centered between the other two! (If it was on the outside and the other two were next to each other I’d be having seizures, LOL)

Here’s some photos because I like photos more than words. I opened up a spare valve I had at my desk today to see if it comes apart. It does. Here’s what it looks like.

Holidays and some bad weather have given me some delay. Getting a little break in the weather, so able to start working with it a little.

Got the flowmeter hooked up now, pretty much ready to start testing and get some data.

All you OCD types might want to look away… haha.

I hope this doesn’t irritate you too much, but the flow meter is directional, bottom to top. The flow of water pushes the weight UP and it’s calibrated for vertical flow.

Ah, ok… yeah i’ve never used one like this before. The drawing makes sense.

Easy fix, no biggie.

This would be a lot more interesting if the was some burnt metal involved. Y’all come to Fuquay Varina and let’s doing some welding and tinkering on it

What size is that white pvc output side? looks a lot smaller than the intakes.

It’s 3/4", same as the poly hose… just looks smaller in the pic. The valves are 1". My entire system was plumbed with 3/4", so i’m going to use all 3/4" to test first, and then may swap in some 1" intake lines to see if it makes a meaningful difference later.

Since the metering valves are apparently restricted, even wide open, then you cant get a full 3/4" flow unless you step up to the 1" valves. Same with 1/2"… cant get a full 1/2" flow unless you use 3/4". At least that’s how it appears on paper… hoping to be able to see just how much restrictions there are with these valves with some testing.

Also, to make sense of that setup, for anyone that is wondering… the white pvc on the left is the incoming water supply from the house… it goes straight up and into a hudson float valve. The branch to the right with the ball valve is to direct the house flow to the booster, in case i need it to get an initial prime. Once primed that valve will be closed, and then the mix from the metering system will flow to the booster.

any update on the set ups ?