That would be your first troubleshoot.

@Harold Have u run it out of fuel recently. Sounds like u need to bleed the fuel line. Air in the line not priming. Did u bleed the line after changing the fuel filter?

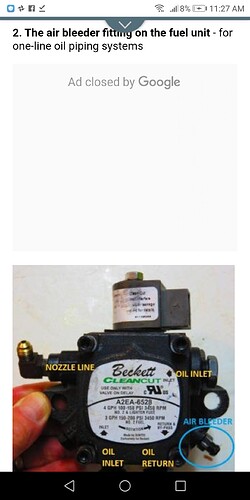

Stick a hose on the Barb and stick it in a clear jug. Back off the Barb and get all the air out till u get good fuel. Like bleeding brakes.

First thing is to get a hot battery. 11 volts might turn the blower fan but not ignite burner. battery may not be the problem but start with the easiest first

If no air in the line and u are getting good fuel pressure. Flip it down and make sure your nozzle isn’t clogged. Don’t take munch to clogged it.

If the pump has a return line which it does it will never need to be bled. It will self prime in seconds.

That is incorrect.

Ok bud  so according to the picture you posted I should also run two fuel supply lines to it huh? Lol

so according to the picture you posted I should also run two fuel supply lines to it huh? Lol

Recently had problems with mine. Called pressure pro and talked to the service guys. They were excellent and talked me through what to check. They were very specific on battery voltage. Needs over 12 volts to fire and run properly. (think it was 12.4 volts) Pressure Pro guys went above and beyond to help. That would be my first check. They said lots of people have problems due to voltage. Mine ended up being a bad pump from water in the fuel. Caused the inside of the pump to corrode and block the bypass. Continued to dump fuel into the burner with no ignition. Started smoking then caught fire (minor). Ended up replacing the fuel pump and all the insulation around the coils. Everything works great now.

Lol that is also incorrect  I never said to install two supply lines.

I never said to install two supply lines.

Do you just love saying You are incorrect or something? I was making a point that not every port is used for a given application. Same goes for the bleed nipple, it’s put there for single piped systems with ummmm hummmm no return line being used

Interesting that on the same web page you pulled that pic from, right above it, it clearly states the bleed nipple is used for one line piped systems with NO RETURN lol

Have to agree there. Bleeding brakes was used as an example above. The reason you have to bleed brakes is because it’s a closed system. There’s no where for the air to go, hence the bleeder screw. In an open system the return line is in effect the “bleeder”. It’s an open system so the air gets pushed right back to the fuel tank.

Wow guys thanks for all of the replies. The power of PWRA. I received a phone call yesterday not long after I made this post from a daily member here that does more reading then posting (Thanks Joe). We stayed on the phone for over about an hour trouble shooting and although it’s still not fixed I’m getting a better idea of a. How all this works and b. How to trouble shoot it. I just checked back on this thread and it’s a lot more good info on what to check.

@Kps0410 @Jordie @DisplacedTexan @dperez @Maelstrom @wildmtn @Firefighter4hire @Hotshot @Coolunderpressure

I thought I had it fixed momentarily when I disconnected the positive battery cable. Engine continued to run and put out 14v. Started the burner and it fired up. I installed a new battery and then the burner stopped working again.

Yesterday I replaced the battery.

Determined that I’m getting 14v from the rectifier.

Attempted to visually test the pressure switch but I couldn’t see it engage or disengage. I plan to bypass it today to test it. Here is a picture of the pressure switch. Any idea which leads to jump? Can I damage it by guessing?

I plan to test the fuel pump by dissconnecting the return line.

Check the solenoid inside the junction box entering the burner. Any idea what wires to check? I’m assuming I should have 14v somewhere in there. Is there a way to check the part itself? Here is a picture.

I forget the name of this green capped part but I tested the female plug yesterday and I’m not getting any power to it. I’m going to try to figure that out as well. Here is a picture

So at this point I’m thinking it’s a problem in that junction box since I’m not getting any power to the female plug that connects to the green cap. Next I’m going to try to jump the pressure switch.

PS: forgive my lack of proper terminology. This is not my forte. I prefer to drop it off at the repair shop but more and more lately I’m having to learn this as I go since they have a 2-3week lead time to even look at it. I’m considering purchasing another 8gpm cold water skid for times like these. I could get away without the hot water for a few weeks but I can’t make it work with only one machine on the trailer.

That “green cap” looks like the fuel solenoid. It was mentioned that it seemed to be a fuel issue so that would explain it. Since you’re not getting power to the solenoid you’re likely correct about it being a problem in the junction box. You might’ve already done so but trace the wires to the junction box. By trace I mean making sure you have voltage up to the junction box.

Harold in the pressure switch there is a tiny pin that sticks out of the bottom of the switch take a eye glass screwdriver and move it up and down make sure it not sticking

I just checked the ignighter and no juice. It’s looking more and more like a power issue in the junction box.

Do you have a wiring diagram? Each safety component basically prevents power from getting to the next component. If the pressure switch is bad power won’t make it past it. That could be preventing it from making it to the junction box. I stick to your next step of bypassing the pressure switch so you can rule it out.