Are you using the same unloader for both setups, and adjusted to each different setup?

Yep…

I’ve had mixed results with my 19” 4 nozzle as well, half the time it stripes so I have to 3% post treat more than I prefer.

You boys don’t know what’s coming, wait till racers done with yoga.

Great. Now all I can think of is Rick in a leotard trying to pronounce different yoga poses with his thick accent.

Im running a big guy with a 4 tip bar but im using a 10.5 gpm. I think im using 25030’s but it works perfect for me. I know our setups are different but on concrete that isnt super dirty and your unloader set properly it should clean like normal

You’ll have a hard time running a 4 nozzle with anything less than 7 gpm. It just doesn’t float as well. Really no need to. That sucker will clean great with 2 nozzles.

I don’t even want to get started with this thread. The only thing I’ve seen so far in it, is it just proves you don’t have to be very smart to be successful in this industry.

Simple solution - put a 2 nozzle bar back on the Big Guy if you were happy with it. 4 nozzle bars are a recent event past 4 years and there was plenty of concrete cleaned before then and since then with 2 nozzle bars. It’s more hype than reality.

What are the stated specs on your machine/pump and how many feet of hose are you running?

What nozzles are you running on your 4 gpm machine and what type surface cleaner are you running on it? WW doesn’t make an 18" so it must be some other brand. Either way it probably has 2502 tips in it, which depending on how much hose you’re running is giving you a lot of psi on the surface, meaning you’ll probably etch a lot of residential drives unless you’ve changed the tips, which I doubt you’ve done, or is that why you’re adjusting your unloader?

How did your new tips get clogged on a brand new bar and why would you run an awl in them. The holes are tiny. They’re probably ruined. Put a pressure gage on right where you connect into the surface cleaner, see what you’re getting and then turn it over and hold the bar while you run it to see what your spray pattern looks like.

Get back to me.

PS: Do like everyone said and set your unloader to the specs of your machine and never touch again.

That’s huge for me. Thank you for that. That’s what I’m noticing for this thing.

That’s what I was thinking, Rick. I loved the two nozzle, but mine is eaten up so I’ll have to get another if I still don’t like this thing.

I’ll have to check the pump. It has two different settings depending on the motor you have. Not a very helpful answer there. Sorry.

My 4gpm is a BE not WW. It’s the two tip and it works great. Usually put 200ft Max on the 4gpm. I was running 300 on the 8gpm for this project. I’m def not eating residential. I’m super careful about that. Usually I have my unloader 7 turns out on the 8gpm and it does a great job with little pressure. The 4gpm I keep turned out too. I read on a post one time where you said you usually don’t clean with more than about 2200lbs and I was finding mine set at 2500lbs was perfect. I have only been messing with this unloader to try to tune in the 4tip for just this job.

THATS EXACTY WHAT I SAID! It really got my goat. It was some kind of grease mixed with something. Idk what. But it clogged three of the four tips. I think it was left over from the factory or something. The machine never gave me issues before.

I’ll check pressures today. Usually to the handle I like to see about 2500-3k. I’ll be higher since I changed the unloader pressure. I was always keep the unloader way under pressured but I only touched it to see if it made a difference for the 4 bar. Which it didn’t do much.

@Racer It came with 2 holes capped so I bought new 2503 nozzles and spares for it and plan on running just the 2 exactly the way Donut had it set, Thank you Rick !

Now when I liquid nail casters on top and flip it over to use as a undercarriage cleaner every so often can I then run four noozles ?

Yucka,yucka…

What brand is your machine and pump. It’s probably an 8.5 at 3600 with the TSF2021GP. If it is, take your green tip and with your whip hose or a short piece and set your unloader. Don’t touch after that. The more variables you can eliminate the better you’ll always be when doing diagnostics.

WW buys the nozzles, they don’t make them and I don’t see how grease would get in on a new arm. but that said just test them to see if they’re ok now.

A lot of reasons the small will clean better. First being with the 2502 tips and 200ft of hose on a 4gpm 4000psi machine you’re shooting probably close to 3600-3700. You need to change your tips in it. Think I ran 2503 or 2502.5s in mine. My little 4 with 19"classic always cleaned great, was just slow.

2500psi is perfect for most. For commercial you can run closer to 3000. With 300ft of hose you’re losing 900psi due to hose before any other restrictions, ie heater or whatever.

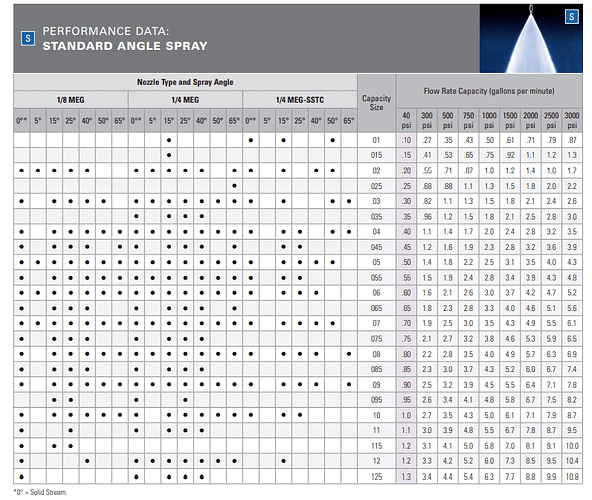

At 2500psi a 2502 nozzle will only flow 1.6gpm - so with those nozzles you’re not getting full flow from your 8gpm. At 3000psi it will flow 1.7 gpm so with 4 nozzles you’re getting close to machine output at high pressure.

The other reason you may be getting a clean differential, is check your height from tips to surface.(usually bottom of skirt on a floater but with wheeled unit be be different) You may need to adjust. Even a 1/4" difference can be pretty big.

Leave the guide veins in. Those are call IMEG nozzles and are designed to minimize turbulence and they also give you a better impact area. I would never run a SC with regular nozzles unless a dire emergency. Best place to buy replacements is KEC, they’re a few $s cheaper than WW. for the nozzle.

Also, don’t rule out that you may be going faster with the Big Guy. You still need to move at usually slower speed with larger SC. The speed improvement comes from the extra width, not how you’re moving. Reason on smaller jobs may be quicker with smaller SC.

Damn @A.M.P.W your getting the royal treatment on this thread !! Tons of good information on here.

And the occasional ribbing to be used as a buffer in between intermission. GOOD stuff…

With the way you’re going to be using your WW you really should upgrade to the aluminum extreme cover. You could mount the casters with small. Pan head screws. And now that I think about it I have an aluminum orange in 19" I’d be willing to sell. I accidentally ordered the orange but wanted the blue. I could see @DisplacedTexan wanting it cause it matches his Longhorns. Here’s what it looks like. Much better than the cheap plastic especially since you’re running hot water.

Dang! I do like that. It’s more Oklahoma State orange than Burnt Orange but still pretty cool. One of these days when I get to be a real professional like @Hotshot I’ll be able to afford a Whisper Wash. Still rocking my 21" stainless steel surface cleaner WITH CASTERS (looking at you @Hotshot). I like @garry.cooper’s blue Whisper Wash units. They’d match my trailer perfectly. I’ll trade ya a brand new one time used M5DS for one, Coop. Whaddya say?

I meant to order the blue the first time so had to reorder to get it. That’s why I’m stuck with an orange too. If I have to pay shipping to send it back I’d rather send it to a fellow washer.

Got dang it that’s sharp! I need one.

Thats purdy @marinegrunt !!! mines yellar.

But im gonna use mine to SC the sidewalks on a couple banks I gotta wash.

You actually have banks? I thought you all buried your money in Mason jars?