Alright, it’s coming to the end of my third year of doing this house washing thing as a side gig. I have the day off today spending it at home with a kiddo with cough and slight fever. While he’s napping, I thought I’d put “pen to paper” and scribble off some things about how I have done it over the past three years and if you care to waste your time reading something…well…here it is.

Preface:

This is not an instructional guide on how to get rich quick. This is not intended to tell you how you should do your build. The “techniques”, processes, materials, equipment, etc that I have used are not items you should run out and implement/purchase to make your business better without careful consideration and due diligence on your part when it comes to research. Most on this site/forum are light-years ahead of me in experience, knowledge, volume of washes, years in the business, equipment, technique, etc. If you’re a new guy/gal wanting to start up a small business I’m here to state that this has been my experience and that it has worked for me.

Okay, washer porn time:

I started this side gig as a part time job to make some extra money to help pay the bills that the full time job wasn’t able to cover. There’s a lovely long backstory to all of this, but you don’t care and I don’t want to type it all out. Here’s the cliff notes edition: I needed to find a way to make extra money since as a family we were living well past our means. No money upfront meant no money to spend on equipment / supplies that were actually intended for this line of work. As business grew, I was able to make modifications / upgrades here and there with a little bit of the cash as most of the proceeds from the business went to paying the family’s bills. Thanks to a supportive wife, understanding children, knowledge gained from this forum, a decent work ethic, a few bonuses at the full-time job, tax returns and a few stimulus checks I can say that we have dug ourselves out of the financial disaster we had created.

Like a lot of folks, I started with a pressure washer from a box store. I went to Home Depot, used the last of my credit line with them, and bought a DeWalt branded washer and a few jugs of Clorox Outdoor Bleach. The washer was a 4,000 psi, 3.5 gpm AAA triplex direct shaft pump bolted onto the Honda GX270 engine. All of that came on a typical pressure washer cart with a 40-ft hose and a wand with the usual red, white, green, yellow and black tips. I’d lift that unit in to the bed of my truck along with a ladder, garden hose, and an empty five gallon bucket. Once I was at the customer’s house I would unload it all, mix the bleach into some water in the five gallon bucket and then drop the siphon tube into the mix. From there, I’m sure I looked like every other homeowner with a pressure washer trying to clean the side of their home. You know, using a ladder to reach anything over 8-ft tall and keeping the wand only about a foot away from the house siding being cleaned. It was all I had ever known to do, it was working by mine and the customer’s standards and I got paid. It went just like that for the first year of me doing this.

By the end of the first year I had stumbled across this forum and decided to try this “soft washing” thing that would supposedly allow me to work faster, use the ladder less, fatigue my body way less, and I’d get to stay dry (mostly). An order of a j-rod, downstream injector kit, and gallon of surfactant was ordered and I picked up some 10% chlorinating liquid jugs before I went out to do my first ever three houses in a day. And I did it. Instantly I knew that this was going to be a game changer.

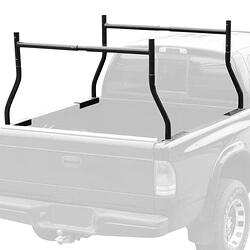

I eventually built a ladder rack for the bed of my truck out of 2"x4"‘s to hold the ladder and to hang my hoses on. I picked up another 50’ section of pressure hose and then another before ultimately leaving the pressure washer (on it’s cart still) in the bed of the truck. About halfway through my second year I took the washer cart out from under the pump and engine and mounted the setup to a wooden platform in the bed of my truck near the tailgate for ease of accessibility. I quickly realized though that with the configuration of the direct drive pump and the hoses coming straight out of it that it left me little room to squeeze in the newly discovered 15 gallon drums of pool shock I was toting around. The beginning of my third year saw me moving the washer up near the cab of the truck allowing more room near the tailgate of the truck - afterall, this is still my daily driver and I like to use my truck for truck-like things such as picking up a few bags of mulch or fertilizer, or hauling the kids’ bikes to the local playground, etc.

I realized that I had the engine too high for my liking and lowered it quite a bit. Having it so high up made it harder to fill up whether it was with a five-gallon fuel can or directly from the gas pump, but lowering it made a world of difference. And with me running the same mid-grade fuel in the truck as I do the washer, it makes it a lot easier with the gas tank of the truck and the gas tank of the washer being so close to one another.

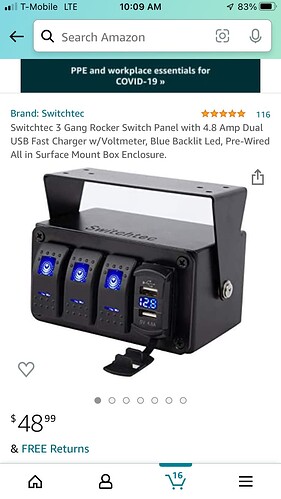

Also, at the beginning of my third year I started with hose reels and a 12v pump. The hose reels are like the rest of my build - budget minded. But they do the job. The 12v pump allowed me to transfer fluids exponentially faster for my batch mixes as well as allowing me to tackle a few roofs, although it usually only comes out on the jobsite when doing a severely neglected driveway.

The rubbermaid storage box shown in the photos stores items such as a spare o-ring kit, tape, bags, spare fittings, spare downstream injector, a sample kit of chems from PressureTek, etc.

As for what I intend to do for the upcoming off season: I’m likely going to build a new ladder rack system (and, yes, it’ll be made of wood again). I like the general layout of what I have going on currently, but I want to free up a little more floor space and maybe lower the batch mix tank to sit down on the bed of the truck. I’ll also be working on building a 12v storage box, perhaps a water filter system to catch debris coming from the supply line and before it enters the pump, and maybe, just maybe, look into using a remote fuel tank to extend run time on the engine of the washer. Right now, I get about 3.5-3.75 hours of run time per a tank and I usually just refill with the red gas can before I leave the finished job so that I’m not having to do it as soon as I arrive at the next one.

For now, I’m sticking with the same washer as it’s done everything I’ve asked it to do and everything that I can foresee that I want to do. Single and double story vinyl sided homes are a plenty in my area and that’s exactly what I target. This past year was my busiest yet, and the most profitable for sure, but that doesn’t guarantee that next year will be the same or better. I just got in a new gun and j-rod even though the old ones were still working (the old gun dribbled a little) and I’ll keep them on the truck. What wasn’t seen in the photos was a spare 50-ft of pressure hose that’s still coiled up under the back seat of the truck as well as the hand-held blower I use from time to time.

This isn’t a record-breaking set up I have, nor was it intended to be, but it has helped to produce what my family feels is a substantial chunk of money. So if you are just starting out and are looking for some inspiration hopefully this helps. But, as I suggested at the top of the post, do your own research to see what is going to best do what you need it to do. I never wanted to clean homes with 4 levels, parking garages, commercial buildings, apartment complexes, fast food drive-thrus, or dumpster pads. Give me a 1,200-2,800 sq ft single or double story home and I’ll wash it gladly with what you see, a less than pretty, economy style, basic truck bed build.