You’d be about right, except that benchmark was about 30 years back lol.

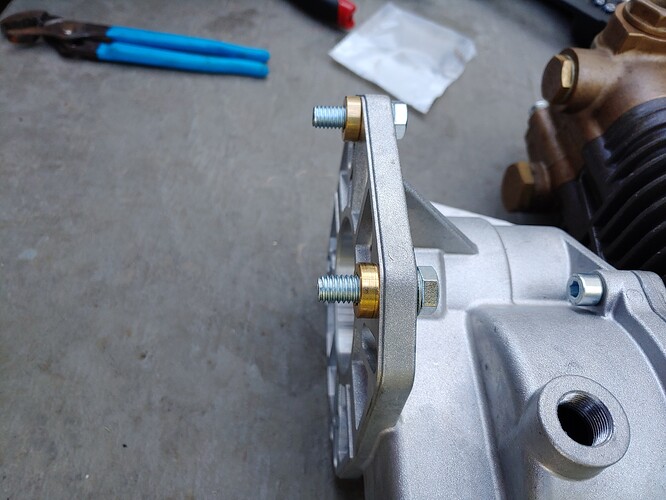

The reason why my gearbox was leaking is because I didn’t put the spacers on the bolts in between the gearbox and machine.

The shaft from the engine punched a hole through into the gears causing the oil to run down the shaft towards the motor. Here is the part it broke.

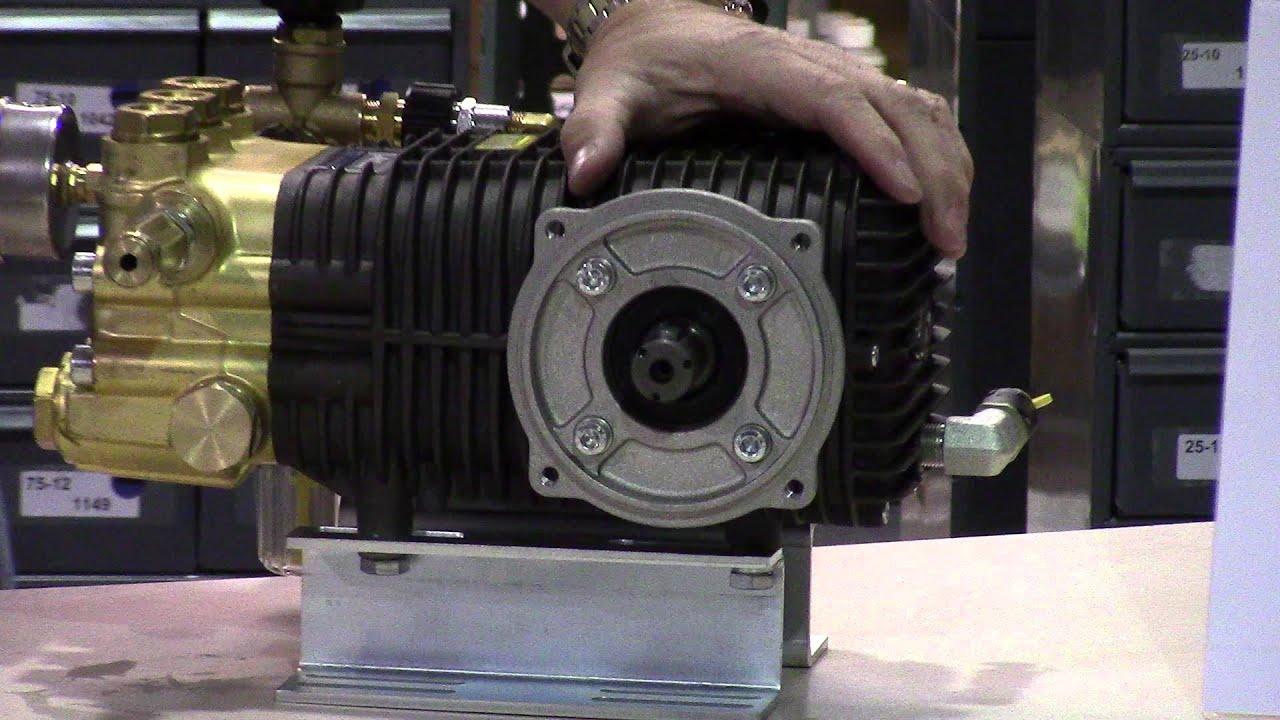

Envirpspec was extremely helpful. The over night me the gearbox and gave me a $70 discount. They also sent me a Youtube video on how to install the gearbox to the pump.

Were the spacers not included in the original gear box kit from them, or did you just forget to put them in?

Either way, glad to hear that you got a fix.

They included 2 sizes and no direction on what to do. It was my first build so I was clueless. I asked around and was told that I didn’t need them. I should have called Envirospec first.

Amen to that brother! All this gear drive, poly chain drive, yada yada yada isn’t worth the time it took to write this post. Buy belt drive. Go make money. Spend $40 on new belts once a year. Hell, be overly cautious and do them twice a year if you want. Out of the few dozen belt drive machines I’ve ran I have probably only had two or three belts break. They usually just wear out and slip. If you know your machine well enough you’ll be able to tell exactly when that happens. Easy squeeze.

And HIS recommendation on 100hr OCI’s is a big no thanks. I readjust belts once they stretch after about 30-40 hours and once again when they loosen up. That’s it, then they get replaced when they start to crack between the cogs. If I had to do 100hr oil changes or anything close all along the way it would be disappointing to say the least. I understand most guys that run gear drives don’t keep up on the oil anywhere close to that but still.

I couldn’t take my eyes off those pump rails though. Man they were beefy, I wonder who makes those particular ones???

Who makes them?  It’s 2 aluminium C-Channels with 4 guides. You pre historic belt adjusting acid spraying gel wearing caveman, make em yourself lol.

It’s 2 aluminium C-Channels with 4 guides. You pre historic belt adjusting acid spraying gel wearing caveman, make em yourself lol.

What’s the difference between changing belts and doing an oil change once a year. Most of these geardrive issues on here has to do with how they are put together by the owner. I’ve lost count of how many geardrives ive had, never had any issues if I assemble them myself. I can’t be that lucky ![]()

Number one those are STEEL broski. Two it’s not C channel as one leg is shorter in length. Three I already do have my own made. They are press braked after they have been water jetted. Mine are one piece not two rails. It makes a platform under the pump. They are thick because I kept cracking the GP rails but they are expensive to have a run made up and I need some more. Much better idea to buy some heavy ones that are already done for me.

Next time you’re building one you need to do a full write up with step by step instructions and preferably video the entire process and post it up here so guys like @dcbrock can learn something and maybe prolong their pump life. That still won’t make it nearly as foolproof as a belt drive system is. Belts and pulleys = way easier to grasp than gears, splines and shafts for the layman.

I only went with a gear drive because I couldn’t get that flippin’ pulley off. It still sits in my garage, belt shield and all.

Oh and as for assembly, I made sure to blue loctite every single bolt and set screw. So far it’s working as it should, just really sparkly.

I could write a whole damn book and video an 8 part series on them, what’s the point no one reads on here lol 20 damn “witch 2.5gpm pressure washer is right for me” threads a day. If you can read instructions and assemble a pepperoni pizza and put it in the oven you can assemble a damn geardrive.

If I remember correctly @Innocentbystander had a slick setup witch I liked with a threaded rod for adjustment, super nice, super simple

Mine is similar. I run the tension rod in the center of the pump and weld angle iron on the sides of the pump rails so it slides forward evenly.

Yes sir, I have to somewhat tighten the opposite corner and “drag” that end so the pump draws straight.

So you gave yourself a self inflicted wound, Destroyed a perfectly good gear drive that did nothing but try to please you, lost quarts of oil and some time and learned a ton of intel and they still gave you a $70 discount . Thats pretty darn good in my book man. Glad it worked out for you Bill. ![]()

Im still marking it as gearbox failure on the calendar though fellas.

It was my fault not the gearbox. I didn’t put it together correctly and it was a relatively easy fix after it was diagnosed correctly. I was my first build and I wanted to learn more about how to build a machine that was why I used cheaper motor and pump figuring I didn’t want to make a huge investment if I screwed it all up. I would definitely go gear drive again over belt.

Theres a few output shaft variences, some are 4in some shorter. Im guessing.yours was the 4in variety,.therefore.needing the spacers.

Predators must have longer crankshafts. I’ve slapped a gear drive on both a Honda and Vanguard without spacers and have never had any issues. I ordered my gear drive from Envirospec and they never included any spacers.