Pressure washer all day using RO water at 38 ppm out of. There was nothing else available. This is probably the cleanest water I’ve ever worked with. However, I noticed that the gun had some vibration and then while using the turbo nozzle, it kept cutting out and then starting again, as if it was starving for water. Did some basic troubleshooting, buffer tank was over half full, cleaned out the filter it had some Pineneedles in it. Checked the oil in the pump and the oil in the pressure washer and the fluid in the radiator on the Kabota motor. All was good. Changed the gun as I noticed the gun started feeling a little weird like the trigger was stopping short a little bit but that did not make a difference. Tried just using the gun with no tip at all to make sure it wasn’t a clogged filter in the turbo nozzle. Any idea what could be causing the vibration in it and cutting out when on the trigger to randomly cut out?

Orings in the quick disconnects on the hoses?

Interesting I’ll Look at those !

Sounds like your unloader is acting up but my knowledge is next to nothing on that aspect of these machines. Its a thing to look into though

Sticky unloader can give you some of those symptoms but I’d probably be leaning towards a stuck check valve in the pump.

In my very limited experience, if your engine doesn’t have enough umph to handle your unloader settings at higher gpm, the engine will stall when using high pressure nozzles.

The oil in the pump is milky and way higher so it’s definitely water in the pump. Can I keep running it until it completely dies or should I shut it down and try and save whatever might be left until I can rebuild it? Big jobs all this week they can’t really be rescheduled…

I am no hardcore veteran but just dealt with this myself. I emptied out the pump oil and got as much of the thick gross stuff I could out. I refilled and ran two jobs on it like that. I had to out of necessity. Idk if you can buy a pump quickly or not but I couldn’t.

Is this something that could be done on a backup 4gpm unit until you get it fixed? It’s that or swap fluids between jobs and hope it lasts.

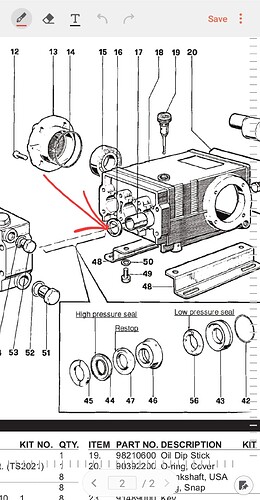

Or…you could hopefully get a pump repair kit locally, take pump off and replace seals and then put the pump oil in. Shouldn’t take you long at all even if you arent mechanically inclined and there’s YouTube videos. I feel like what you have available locally might dictate your options but those are the three that I see as a newbie to the game.

Your best bet would be to take this unit out of service and use another until you can fix this one properly. You can take a risk, flush the oil, and monitor it closely, but the cost could be complete pump failure.

Update (delayed) I ended up having the pump serviced and replaced O-rings. Due to the placement of the pump being close to the AR 45 and having SH leaking all over it here in there throughout the last year or so, it took them forever to get one of the bolts out 4 hours for the bolt plus 2 for the rest of the work to be exact. They had to weld a bolt extractor to the bolt that got stripped trying to remove it with the allen key, and then weld an impact socket to that and then use a high torque impact gun to break it free! It was ridiculous. My bill for a pump rebuild was almost $900. Not to the fault of the good folks at Northbay Equipment. They actually really helped me out in a pinch. But what a nightmare!

They should of just used the wire pulling lube

With that being said, I’m still having issues where the gun is cutting out now every 5-10 mins or so and then works fine again. The pressure is down to only 2500 psi before the hose reel, but it keeps cutting off like there’s too much pressure. I’m wondering if the ZK1 unloader just needs to be replaced? I checked the pump, the oil is very clean, at the correct level and not milky like it was after the O-rings had failed. The water filter is clean and has plenty of water in the buffer tank. The oil in the motor is full and seems to be running just fine. I’ve been using the turbo nozzle for a few days in a row now but even with switching to the regular size 9.0 orifice tip it’s doing it and also with the surface cleaner using a different gun. I did clean the filter out in the turbo nozzle because I know that sometimes if that gets clogged it will cut out like that. Heading back this morning for another long day of turbo nozzling. I’m wondering if turning down the pressure even further will help me get by until I can get a new unloader in, or if the problem could be something else unrelated to the unloader?

Without dissecting all of this, you need a better vendor. And pumps don’t have orings, except around some check valves, so not sure what that is about. You really need a vendor who can work on pumps.

Get a new ZK1, not having extra unloaders sitting on the shelf is like uhhhhh what are you thinking. The unloader is taking a dump into the bypass “circuit” due to wear. You can run a nozzle that’s a bit worn or increase the pressure a smidge on the unloader to get you by.

Great points! I recall @florida_condo_cleaning mentioning going through these with regularity.

@Seandz How old is yours?

Be careful. You might summon the wrong guy. lol

Good point! I thought my screen had the letters cut off. @florida_condo_cleani

One time a guy summoned @thefakeQons. He hasn’t been seen since.