I also hear a lot of people using cam locks in some locations for some connections. Do you like them as well? I know racer likes using them.

Good to know.

Speaking of leak everywhere, how about fuel hose randomly coming loose on spare pressure washer in customer’s driveway after you washed said driveway?

Don’t forget to carry cat litter…

Tough luck! Tidy cats is the best

Leaking fuel lines are the worst!

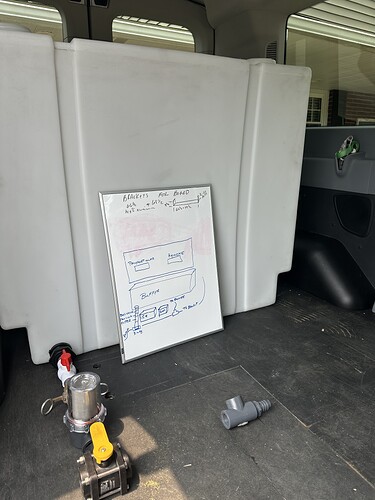

Ok so next question of interest…. I was about to plumb this beast when I was told that I should run the softwash inlet separate from the pressure wash inlet. I was almost all set to run both off the same line. Any thoughts?

It’s so easy to run a separate bulkhead, I suggest just doing that. The more fittings coming off your bulkhead, the greater chance for a vacuum leak, which could cause your pressure pump to cavitate. (It’ll also drive you nuts trying to maintain prime with your soft wash pump)

Next dilemma. Been told by many that I should feed the remote proportioner from the top of the tank? And in doing so I see many using either uniseal( is that right?) or bulk head with pvc tube down to bottom with filter. Any preference in your opinion?

Uniseals are great I think, when the application calls for it.

Whaaa? How have I not heard of these before? They look like a perfect solution for this sort of application.

Ya I really like the concept. I think. Lol. I see a lot of people using these on the builds, to me I like that there are no air leak possibilities through the tank and apparently on these ar-45 systems that is important.

Well the rig is completed as of last week but already wanting and noticing I need some custom modifications. Lol. Has anyone ever taken the electric hose reels activation buttons off and located them in a remote location? I was thinking of relocating just that buttons to just inside the sliding door, it is actually a bit of a pain in the a%% to wind the hoses up from way inside the van.

Relocating the controls for your reels should be no issue (just remember to disconnect power before fiddling with wiring, lol). I’d be interested to see how you manage guiding the hose back onto the reels while winding them up, though.

Build looks good ![]()

Edit: are those self-tapping screws holding the hoses onto the plastic panels though? I’m curious to see how long they hold before wallowing out the plastic.

And I assume you’ve found some way to secure those smaller chem tanks, right?

It looks like you did a very nice job. Are you using a 3/8" ID high pressure hose on the AR 45 to the hose reel? I would recommend using t-bolt style hose clamps on the pressure side and anything with chem being in a van. Either way watch any style hose clamps until they settle in our your in for a big mess.

Getting the hoses back wound up has become a little challenge. I need to come up with something to help guide them because it’s so hard to keep them from snagging on stuff especially on the door opening and I feel if I can locate them just in side the door we can guide from there. Lol we are gonna experiment with one pushing the button inside as they are while one guides from the edge of the door opening. Lol. Ya the softwash hose I had found out really moves a lot especially between bypass. And as far as the sh and soap tanks I haven’t made a decision to go bigger on sh tank the 22 gallon goes very fast.

Yes I made up a whip line to the hose reel. Yes I would like to use to my clamps , I heard they are great but have big hard time finding them

I bought my hose clamps at Tipco I believe. Not cheap in the hose clamp world but they seem to hold good.

I have no idea how much impact forcing the discharge from the AR45 into a 3/8 whip line will make but I know it isn’t helping your performance. I would recommend a 3/4 or at least 5/8 line from the unit to the hose reel.