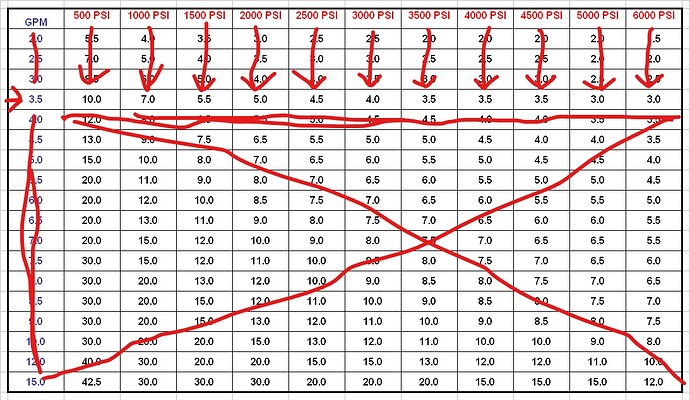

Forget the surface cleaner for now. Let’s just concentrate on one nozzle. When selecting a nozzle the only reason for doing so is to select a different psi. You’re not selecting a nozzle for a change in gpm because that never changes. Your machine puts out whatever gpm it puts out. So, when selecting a nozzle for psi change, it always has to put out the same gpm as your machine. In your case that’s 3.5 gpm.

You don’t have to worry about any other number on this chart. The numbers in the middle of the chart are all nozzle sizes. We’re using 3.5 gpm because that’s what your machine puts out. If you want 1000 psi you put your finger on 1000 psi, your other finger on 3.5 gpm, and where they meet is what nozzle you need. In this case that’s a #7 for 1000 psi. Say you wanted 2500 psi out of your wand. That would be a #4.5 nozzle.

Now let’s figure for a 2 nozzle surface cleaner. Since there are two orifices you have to divide the gpm of your machine by 2 because 1.75 gpm will be coming out of each orifice. PSI stays the same and isn’t divided by two because you’re the one selecting what psi you want. If you decide you want half the psi of say 3k psi then select a nozzle that puts out 1500 psi. You’re in charge of that. Since your machine puts out 3.5 gpm half of that would be 1.75. It’s not always possible to be exact so we’re just going to have to stick to 2 gpm for half. In a perfect world there would be a 1.75 gpm but there isn’t so that’s why we round up to the next closer gpm number. They’d have to make a million different size nozzles for every machine to get exact numbers. A few hundred psi difference that we don’t know is there won’t hurt anything anyways. Okay, now let’s say you want your surface cleaner to put out 2500 psi. You’re not going to look for 3.5 gpm on the nozzle chart because there are two openings on a 2 nozzle surface cleaner. We’re going to divide your machine’s gpm in half so we get 1.75. It’s not a number the charts really deal with so we’re going to round up to 2 gpm so consider that half of your machines gpm. If you put your finger on 2500 psi and your other on 2 gpm the meet at a #2.5 nozzle so that’s the size you’ll need to get 2500 psi out of your machine. If you decide you only want 2000 psi then you’ll need #3.0 nozzles.