My unloader keeps popping a leak in the nipple that threads my pump to my unloader. I’ve had the unloader spring a leak on me twice and replaced it both times thinking it was some wack coincidence or I had my unloader adjusted too high. So I adjusted my unloader much lower, and it happened again today. Why could this possibly be happening?

Is this the unloader and fitting that came with the machine? What did you use to seal the fittings the first time? Is the nipple rated for high pressure? Assuming the unloader is brass, did you over-tighten it and stretch the threads? Apply some blue Loctite to the threads, tighten them snugly, let it sit overnight, and check for leaks tomorrow. If that doesn’t hold, use it as an opportunity to upgrade your unloader and get an unloader block.

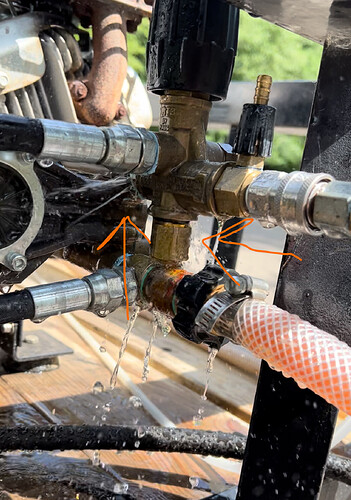

Pics?

It’s brass and rated for high pressure. I sealed it with teflon & blue monster. I may be over tightening it, that’s the last thing I can think of. I don’t believe it’s the same unloader that came with the machine, because I bought the machine used and a new pump had been swapped onto it before I bought it. So I figure that meant a new unloaded too but who knows

It’s also probably worth mentioning that it’s blew a leak in one other spot as well, so I feel like it’s related to an unloaded malfunction like a pressure spike rather than a fitting malfunction

This is when it popped a leak in two different areas. On the bottom piece that has an o ring and finger tightens, and on the connecting thread between my pump and unloader

I’ll let the other guys dissect that mess, but a lot of that needs to be removed/cleaned up.

I already fully fixed it once. That was the second time it popped a leak. All it took was replacing the nipple and finger tightening the part on the bottom and there was absolutely no leaking. Not even a drop. It just looks crazy in the picture because water is running all over everything spraying in tons of directions. But every time it leaks, it keeps popping a leak in that nipple that connects the unloader to pump and it’s the third time I’m replacing it now

I personally don’t like using teflon AND a thread locker for exactly the reason you stated… it makes it super easy to over-tighten. I’m also not a huge fan of blue monster on anything high pressure, I know it’s rated for like 10k psi, but I would rather use blue loctite 242 and save the monster for 300 psi or less.

If it keeps happening the fix was temporary at best, you didn’t fully fix it. It looks like there are multiple places that are leaking in that photo, best to take it all apart and go through piece by piece. Use a thread locker (you should know by now I’m going to recommend blue loctite) apply a few drops to the bottom two or three threads and make sure it connects around the whole circle. Finger tighten everything and then snug it up with a wrench. Let it sit for 24 hours and then check for leaks. The thread locker should help with threads that got stretched from over-tightening… however, being brass, if they are too gapped you will need to get a new unloader. Luckily the vrt3 is a cheap unloader and you can source them easily so unless you are wanting to upgrade it’ll only set you back $50ish.

I would recommend adding a unloader mounting block at the least

I want to upgrade to the zk1 but it’s only rated for 3600 psi and my pump is 4200

You need to get a better machine like a belt drive and buffer tank before considering a K1.

Why’s that? This machine isn’t worth doing all that to it

Exactly. You need to sell and get this.

I finally have a 690 on the way haha but this is my other washer for my helper. Is there any specific reasons why a k1 wouldn’t work with that washer?

I vote get the zk1 unloader sooner then later (especially if already considering replacing that VRT3)… it is an affordable upgrade that makes a big difference… plus it’ll work with your current and future machines when you’re ready to upgrade. The downside, if you can even call it that, like you said it can only go to 3600 psi but for most cleaning tasks, that much pressure isn’t needed anyways. I second @CHogue in getting an unloader block so you can mount it somewhere on your trailer and offload that weight hanging off your pump.

Okay. I’ve been reading about using the k1, and from what I’m reading it seems like I’d have to get an inline pressure regulator between my pump and unloader to protect the k1 since it’s rated for lower psi than my pump. Is this true, or would it be possible to hook it up to an unloader block and adjust it down in psi

From my understanding and someone more educated on the inner workings of it can chime in… but your engine can only output so much power while under constant load. That gets balanced between giving yourr GPM and PSI, lower one of those and the other increases and vice versa. The manufacturer of your machine selected the engine with a HP capable to give you as close to 4 GPM and 4200 psi that they rated and marketed that pump for… if you set the unloader to only reach 3600 PSI your pump will not put out more then that pressure, it will increase your GPM to more then 4, so your GPM will go up, but also some of that will be getting bypassed.

The unloader bypasses 100% of the flow while you’re off trigger. The percentage it bypasses while you’re on the trigger is determined by how you have it adjusted. It increases PSI by increasing GPM as you open it up. No regulator needed. I wasn’t able to get my above 3,000 PSI at the gauge with it all the way open but that’s plenty for me.

So I’ll have to cut back on my gpm in order to be adjusted at a psi point that’s good for the unloader?

No, dropping the psi will give you more gpm (though more of it will by bypassed as well)