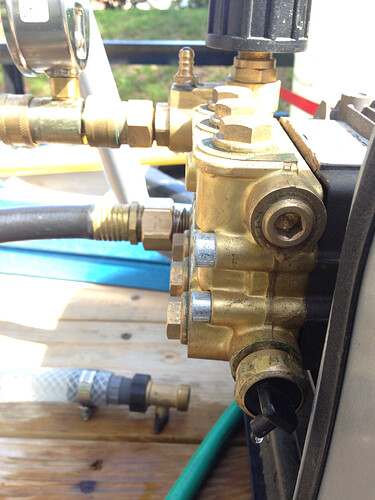

I have a Simpson 4200PSI BeltDrive Cold Water (4GPM) Honda/Comet pressure washer. It’s unable to maintain pressure.

It has approx 60hrs on it. First oil change was done at 50hrs.

Engine and pump oil levels are OK.

Water supply is OK.

No leaks anywhere (EXCEPT the thermal relief valve started dripping lately as soon as I hook up the water supply hose to the pump - I don’t know if this is a symptom of some bigger problem, but it’s been like that for the last 15 or so work-hours and it doesn’t appear to be an issue to me. I tried to research it and wasn’t able to find anything that would alert me).

Anyhow, the real problem is this:

As soon as I squeeze the trigger it gives me its normal initial burst of water and then the pressure drops to nothing. It’s barely trickling out of the wand. If I let go off the trigger, the pressure builds up within seconds. I squeeze it again. Burst. Then nothing.

Here’s the YouTube link to a video that I shot this morning:

Simpson 4200PSI BeltDrive Cold Water (4GPM) Honda/Comet no - YouTube

Some more info about this issue:

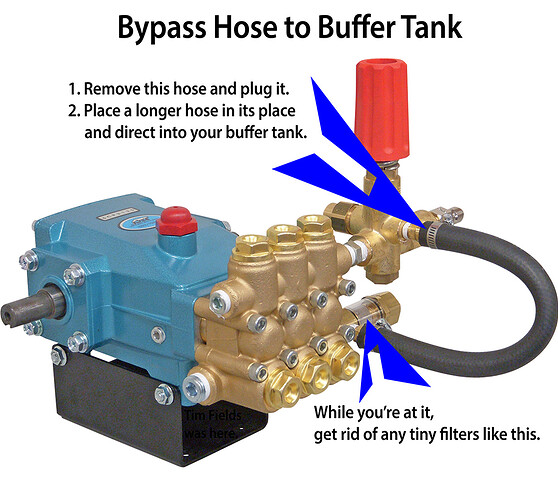

Few days ago I was finishing up a job - literally was rinsing the last wall (I downstream). When something very similar happened. I lost pressure. I didn’t push it and walked back to the trailer to shut it off. And sure enough the buffer tank was empty! I checked the hoses and found the mesh filter at the (upstream of) float valve of the buffer tank full of leaves. They were chopped up to 10x10 mm pieces of fresh green tree leaves. No idea how they got into the lines. I mean it isn’t the rocket science, is it? There’s a well, a pump, a pipe to a spigot, then my garden hose that goes into the buffer tank through the float valve. How did the leaves get in there??

I cleaned it all out. All was fine. I did another job the following day. Larger house, approx 4 hours. No problems whatsoever. Then it sat for 4 days. And this morning I get to a job. And it’s not working again. Checked everything. Flushed the air out of the pump. Still not working.

Any suggestions would be appreciated! I have two jobs scheduled for tomorrow. So please help help help!

Thanks guys!

Alex K. with Northside Power Washing of Delmarva

Sent from my iPad using Pressure Washing Resource