Hello all, I just ordered the whisper wash ultra 16” from Pressure tek it comes standard with 2502 nozzles my machine is 4 gpm 4200 so looking at the charts those nozzles should put me at 4000 psi. Now from what I’ve read that is too much for residential concrete so I was thinking about lowering with new nozzles. So back to the chart where i see to achieve say 3000 psi I need a #5 nozzle devide by 2 and get 2.5. My question is are we looking at the surface cleaner as a whole when it comes to psi or do we break it down by nozzles since we devide the gpm do we also devide the psi in which case the 2502’s would only put out 2000 psi each which seems safe for concrete. I may be overthinking but I really want to be dialed in when my first job comes up. Thanks in advance.

Don’t over think it. Unless you have a 16 hp engine you don’t have 4&4200. Figure in friction loss on the hose and fittings and you are probably fine. Try it out. Changing out nozzles a lot wears out the soft threads on the bar.

I could be wrong, but on a surface cleaner you have two nozzles. If the nozzle is rated for 4000 psi, with two you actually will have 2000 psi from each nozzle. The PSI in the hose gets dived by 2 at the bar with 2 nozzles. Is this correct?

See, now this is why I’m confused too. Previous threads say to replace the nozzles if using a 4/4k machine as smooth residential concrete will get damaged, and there are even pics to prove it.

Now you guys are saying it’s not an issue?

The GPM gets divided in to how many nozzles your surface cleaner has. The PSI remains the same I believe. Someone please correct me if I’m wrong.

IBS is saying that they rated your machine’s specs higher than what it actually puts out. By the time you add in friction loss from fittings, hose length, etc you aren’t getting 4k psi especially at the nozzle. If your machine had a 16 hp engine, was actually putting out 4k psi, and you didn’t have any fittings plus 200’ of hose then you might be getting 4k psi at the surface cleaner nozzles. That could be an issue.

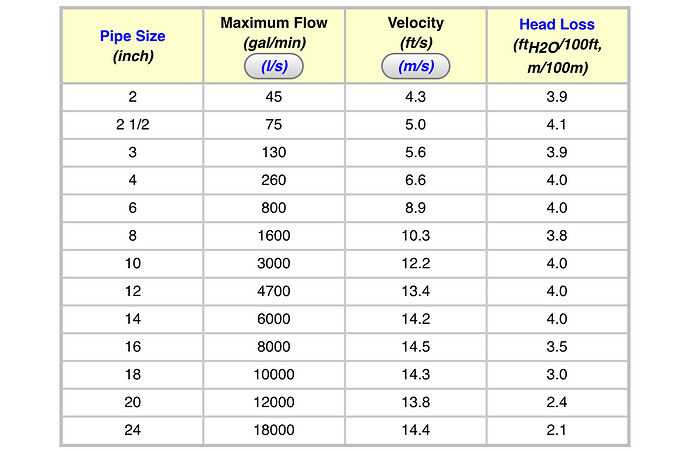

From looking at the chart if you dropped to 2.5 nozzles you would be getting roughly 2500 psi. That doesn’t account for friction loss though.

I used 2502s with my 4/4 and 200 ft hose and it worked great. I’ve heard of others going to 25025s with a 4/4 and they liked it better

I won’t be using 200’ of hose so I’ll probably have to use larger nozzles.

Thanks @Innocentbystander I’ll be somewhere around 180psi loss on just the hose and I don’t know how to figure the fittings yet. There does seem to be some disagreement on if psi is devided or not so I’m glad I asked maybe we can get a consensus.

No, you don’t divide psi. When you’re trying to figure out what nozzles to use your main concern is the gpm of your machine. If you have a 4 gpm machine you never want the nozzles to add up to less than 4 gpm. If you’re looking for a single nozzle for your wand you follow the chart until you see 4 gpm. If you’re using a surface cleaner with 2 nozzles you follow the chart until you find 2 gpm. Dividing in half comes from dividing the gpm of your machine in half because you’re using 2 nozzles. If you were using 4 nozzles you’d divide by 4 and then find that gpm in the chart. You then decide what psi nozzle you want to use.

Put 2503’s on it and don’t worry about it. It’ll clean great.

I used 25020’s forever in my 4@4 - swapped them out to 25025’s and it cleaned a lot faster.

To this day I have no idea why reducing the pressure allowed me to clean faster. Doesn’t make sense.

I’ve since put the 25020’s back in after having too little pressure to clean some flat surfaces.

GPM is cut in half, pressure stays the same on 2 nozzle surface cleaners.

You were probably bypassing some water with the smaller nozzles.

Thanks for that info

I don’t really understand it though, sorry! (If the nozzles are too small = bypass is my understanding)

The nozzle orifice allows 2GPM flow. So that’s 4GPM for 4GPM machine with two in the SC.

If the orifice gets bigger, how does that increase the GPM above the maximum 4GPM of the pump?

Trying to understand

2 small holes can’t flow as much as one big one.

IE, two 1/2” pipes can’t flow as much as one 1” pipe.

This is my simple reasoning anyway… someone correct me if I’m wrong, but makes sense in my head.

I am no math wiz but two 1/2" pipes do not equal one 1” pipe. Somewhere closer to one 5/8-3/4" pipe.

That was my point exactly

Not sure if that was directed at my comment as I don’t get the “one hole” thing relevance to a SC.

A pipes diameter definitely affects the flow rate.

As we are talking about a pin hole orifice, I think the logic still applies, that is - one 4GPM nozzle will out flow two 2GPM nozzles.

That said, how does a 4GPM pump with 4GPM (via 2 nozzles) get more than 4GPM it’s already getting? It can’t. So why do the larger nozzles work better? The pump can only give 4GPM?

People do it to lower the psi. I just use the nozzles that are rated for my equipment and don’t clean anything/concrete that may be damaged.