The one on the invoice is 1 wire . I also have there 2 wire . It’s not a lot more if I remember right

Very easy. Just get the fittings, some thread lock and a couple of wrenches and you are good to go.

I would mention, that changing fittings is kinda of pressure washing 101. I find myself doing it on-site in-the-moment when a fitting fails and I do weekly inspections and maintenance on my equipment. A vice will make it even easier.

It is just a nut & bolt type situation(bolt is the male and the nut is the female). Get the old one off using wrenches (one on the fitting and one on the hose - I truly hope you understand to use the part of both that the wrench goes on). Put thread lock on the male threads of the hose (male is called male as is had the actual threads and goes into, well the female part of a fitting kinda like sex ed) and screw into the hitting (most likely QC). Screw in and tighten up.

Thread lock?

Teff tape is better option

Really?

This must be the unspoken hot debate in pressure washing. I have people swear to me that teff tape is bad as small pieces can come off and clog nozzles and then other swear by Thread Lock only.

I have both in some form or fashion in my set-up and do not notice any performance difference between them. For me personally, my anecdotal evidence is inconclusive to indicate which method is superior.

For pneumatic tools, male fittings generally always come with thread lock pre-applied to the threads.

I have had many a plumber tell me they have generally gone away from teff tape for both water and natural gas plumbing to Thread Seal.

@Innocentbystander why do you feel Teff Tape is superior option?

Are you sure you’re not talking about plumbers putty of some kind ?

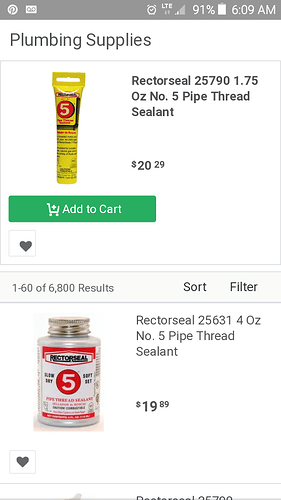

Are you asking what it is? If so, it is a liquid that you apply to the thread to seal them. Works like Teff Tape. Dries quickly and provides a water tight seal in the threads without having the pieces of tape to deal with. See my response to IBS below.

There seems to be two school of thoughts and I am not sure 100% which is better and use both methods in my rig with no fittings or connections leaking. I have used both methods in water and gas connections as well with no discernible differences in performance.

Just did some reading - when it comes to plumbing, often times the city code dictates which method is to be used. The consensus across several articles is that thread sealant or pipe dope as they call it in plumbing is the better option as it is thicker resulting in a better seal, easier to apply (though can be messier) and no chance of shards of the tape getting into the plumbing.

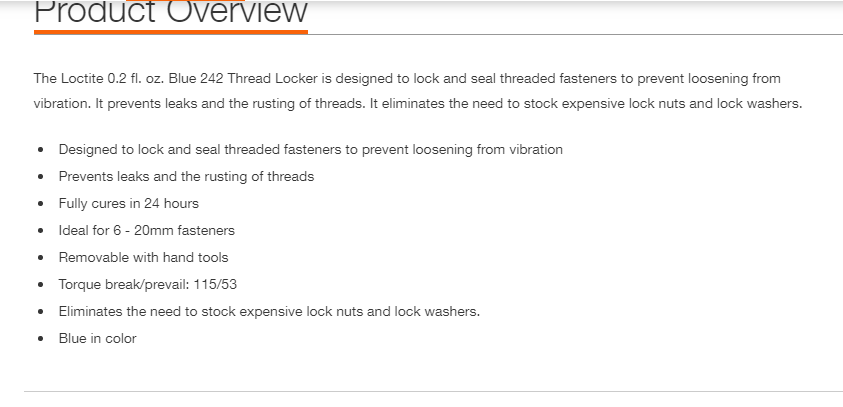

If you use Thread Lock, be sure to get the blue version. The white paste is a more permanent version and way harder to get a fitting loosened up when you need to.

The blue locktite is a thread locker and sealant designed to seal threads, prevent rusting of threads and lock joint from loosening from vibration. It is an all-in-one product.

Doing some more research as I sit here, this seems to be a generally contested topic with no clear winner except in a few situations.

- Plastic Fittings - always use Teflon Tape.

- Larger connections - sealants are the way to go

Everything else, appears to just be personal preference especially when a city code is not in question. The only cumulative consensus that most agreed on is that Teflon Tape as the potential to introduce pieces of the tape into the close system. Could be problematic in air systems clogging regulators or nozzles similar to water systems we deal with. Both seem to do the job of sealing the joint when applied correctly with threadlock/sealant (if you choose this option, but sure to get the proper product - not just a thread lock but also sealant. As @Hotshot referenced some products are only thread locking whereas others have a sealant component to them as well).

For me, I think for metal fittings (hoses, QC, reels) I like the blue Locktite Threadlock and Sealant only for the attribute of not only sealing the threads but also locking them to prevent loosening without having to over-torque the connection.

As an old plumbing once showed me - if you use Teflon Tape, be sure to leave the first 2-3 threads bare. This is the prevent the tape from being inside the connection. I can not say if this is proper technique when applying but it makes sense, I have always done it that way and never had a problem.

Teflon tape will help lubricate the fitting of the 2 fittings, thus decreasing wear of the threads. Always use it on the pump head in my opinion. Plus the pump head is a slight different thread (British) and our fittings are if course National Pipe Thread(American).

I have found that thread sealer crystalizes after time

My Landa guy says it is junk

Easier and quicker to but a 12 packs of Teff tape and spread around the trucks

Personal preference

I always thought thread locker was to prevent loosening due to vibration. Thread locker is different than thread sealant. Both Permatex and Loctite make a locker and a sealant. Usually thread sealants will list a maximum psi. I don’t believe lockers have that rating because it doesn’t apply to nuts and bolts.

Here’s an example of thread sealant.

I use pipe dope on all low pressure fittings and teflon on all high pressure. If you’re careful when you wrap it and don’t have any loose ends or extra handing over hole, there’s no way for remnants to get into your line.

I’m with @Innocentbystander,I’m not waiting for a 24 hr cure time to seal nuttin. I got enough teff on the rig to wrap the moon. I do splurge a bit and buy the thicker Oates teff though. But it takes all kinds I gather,to each his own.