Hi guys I am a plumber and wanting to build a sewer jetter. I am needing advice from you guys that have used the Honda GX 690 with 8 gpm and 3500-3600 psi pumps. I was looking at an Udor GKC 30/24-GR Or the general pump TSF 2021. Ok Heres where i need Help. The honda GX 690 used to be rated higher than what its rated now (24 Hp i think) Now it appears that its rated at 22 Horsepower. Would the Honda GX 690 with the pumps i have mentioned put out 3600 psi with 8 gpm at the pump. I know about pressure loss through hoses and such. So has anyone slapped a pressure gauge at the pump with this setup and checked the psi rating? I’m on a tight budget and just want to make sure before i spend money on the wrong setup. The other thing is i see this setup sold on a lot of sites with the Honda GX 690 so i assume this will put out the required 3500-3600 psi with the 8 gpm.

Thank you in advance for all the help you guys can give me.

3200 psi - works ok with my warthog but better on grease

You can get 3500 or 8gpm with a 690. Not both. Just a msrketing lie from pressure pro that vendors go along with.

I was actually surprised to get 3200 out of it.

@Greg755 Thank you What pump and motor are you using with the warthog and is that 3200 after pressure loss of the hose?

@Innocentbystander Thank you. I figured it was just marketing. So what could i get from this setup? Are you saying i can push the psi to 3500 and lower gpm and then back the psi down and bump the throttle to get the 8 gpm?

Sorry for so many questions.

Not sure what you are trying to do. Sewer jetting usually uses 1/4 hose i believe. That would give you more psi and less gpm.

We have an electric Jetter so I’m not new to sewer jetting and hose sizing. Just new to Pump and motor sizing. We use 1/4 hose in 2"- 3" 3/8 hose in 4"-8 Inch and larger.

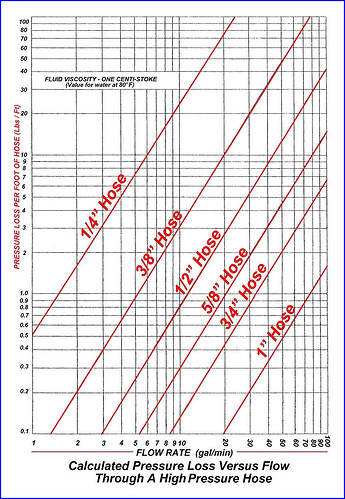

Pressure loss is higher in 1/4 hose than 3/8 with an 8 gpm setup.

This is out of my element but here is a link for udor sewer pumps

I know they make a jetter valve that basically stops one of the check valves and causes the water flow to hammer. I guess the jumping around of the hose helps it get thru bends or tight spaces. Like running a 4 cyl engine on 3. Basic math to determine horsepower is psi X gpm divided by 1100. So, 3500psi times 8gpm equals 28000 divided by 1100 equals 25.4 horsepower. Bear in mind the pressure pro series uses an none Honda muffler which doesn’t dissipate the heat or vent exhaust to Honda specs so instead of 21 hp you are probably closer to 20.

This is some really good info thank you. Yes we use a pulse valve on our electric jetter. The problem with a pulse valve is that it shuts down one of the plungers and causes the hose to cavitate helping us get around tight turns. We dont like using it if we have to(many others dont either) as it puts severe stress on the pump. Thank you again and if anyone has more pump motor experience please let me know. I was hoping to use a honda gx690 but i can go bigger if i need to. Any motor recommendations if i go bigger?

I’ve done vanguard, kohler, lister petter, onan and honda. Currently honda is top of the hill but kohler has gone to efi and can handle ethanol again. Im trying this next

Yea, the Pressure Washers Manufacturers Association is where the true blame lies on this matter.

Per their rating “standards”:

7.5 Pressure and Water flow ratings shall not be

greater than the average of the three samples divided

by 0.9 (allowable 10% tolerance).

here is the link: http://www.pwma.org/docs/PWMA101StandardFinalReaffirmed2016.pdf

This is why you see GX390 rated with 4200 psi. because it’s only a 5% increase in actual pressure with it being “within the standard” even though you’ll never get 4200 psi out of a GX390 unless you plan of destroying your engine fast.

full disclosure: I work for a pressure pro re-seller and I’ve called and complained about this before as I for one try to tell people the truth before they purchase these units.

ALSO! if you your 690 has a generator attached to the belt “115 volt” I think they call them you’ll get EVEN LESS Pressure as its an extra load on the engine.

1\2 x200 hose coming from the pump to the foot valve. After that 150 foot of 3\8 for 3 or 4 inch lines and 1\4 for the. 2 inch and 1-1\2 line. Smaller than that is not worth messing with. For roots and really hard stuff, you need as much pressure as you can get. For soft stuff like grease and sand you want lots of volume or you’ll be there all day. The better heads will be made to match your machines psi and gpm. I have 2 sets, one for the 4 gal 4000psi and one set for the 8gpm3200. You can by off the shelf cutter heads too, that do ok for most residential stuff. Oh and don’t use hot water on grease. And your pump needs a pulse valve.

So greg, on your setup do you just throttle the motor down to be able to bump the psi higher?

You can’t throttle down an engine to get more psi…

When jetting your always going at full throttle pretty much unless when your trying to go thru a bend then you may slow it down to use the pulae valve… But I hardly ever use it because it is not great foe the pump and I have to go all the way to the trailer to engage it.

Thanks for clarification. We currently use an electric hydro jetter for commercial and residential 2 inch lines. I didnt know if gas was different in that you throttled the motor down and then psi goes up by magic or something lol. Ok so greg are you running an 8gpm with the gx 690 and achieving 3200 psi at the pump? 3200 psi is still pretty good. I probably wont be cutting roots much with this unit. I would probably be looking at the root ranger and warthog. Do you cut any roots with the warthog? I’ve heard other guys having good results. At 3200 psi + pressure loss at end of hose i probably will still have root cutting power. It really depends on getting the right nozzle for my machine i guess. Thank you greg for taking the time to answer these questions. This is a lot of money that i am about to spend and experience is the best teacher. (And it sounds like you have the experience)

I have the 630 on the jetter with a comet pump. The overload pops off at just a little over 3200. If you want 3500 or 3600 you would need a 690. Depending who’s pump you are using the psi and gpm will vary a little between them. At the end of the hose it is at about 3100. Even though the pump is an 8 gpm pump I’m

only pushing about 7 and a half gallons. When they made the warthog and the grease cutting nozzle they rated them at 3000 psi at 7 gals a min. Or something close to that. Im not a rocket scientist. I told the guys what pump and engine I had and what the psi and gpm was at the end if the hose and they buit the nozzles. They work great so that’s all I care about. I really don’t care about a couple 100 psi or another half gallon a minute. But don’t worry there are plenty of guys that will pull out all kinda charts and slide rulers that will love to debate this stuff for months to show how technical and precise you have to be… I’m a simple guy, I chase turds for God’s sake. If it works in happy.Thank you greg. All that info helped me a lot and i mean a lot. Thank you so much!!!

Oh and never use hot water on grease lines going to the city sewer.

Hi guys., just want to say hi. I’m new to this forum. I’m josh. I too built my own small Jetter. I too am a plumber by trade.