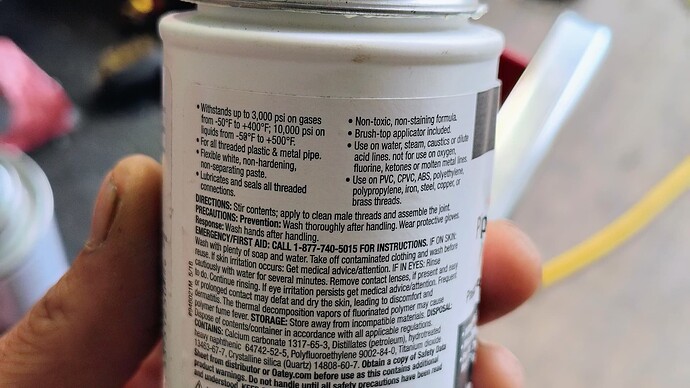

I’m afraid I might have damaged the output threads from the pump. After replacing the unloader, it started spraying a very thin mist. I swapped out the nipple and it did the same after several minutes of use. Thinking that reducing the vibration caused by a rigid connection to the unloader might help, I then switched to the setup pictured with the hose running to the unloader, but same thing. What would be the recommended fix? More Teflon thread tape, liquid thread tape, loctite?

Since I’m here and this is my first post, I figured I may as well submit some pics of my plumbing for criticism and suggestions. I bought the rig fully built about a year ago when I started the business but the plumbing was pretty wack. I didn’t know anything about this stuff at the time but with use I found all kinds of ways it was not well-constructed. And so over the last year I’ve made numerous modifications, learning through trial and error, and this is where I’m at now. Pics in the comments since I can only post one photo as a new user. Let me know, thank you!