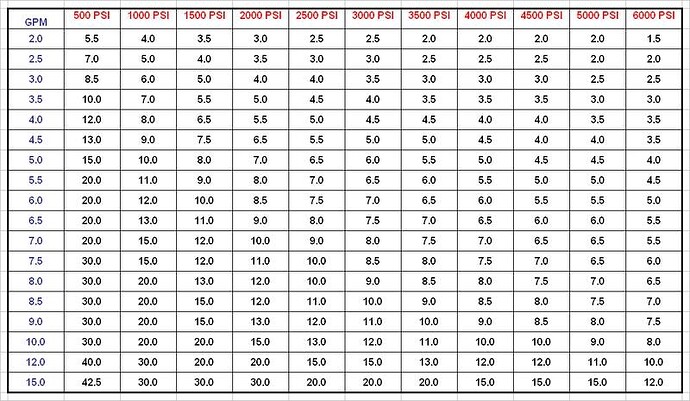

I know I’ve seen PSI/GPM nozzle charts on this forum but saw this chart from pressure wash outlet and thought it was nice.

Thanks Jason!

Thanks I was looking for this

Does this chart apply to surface cleaners as well

Yes but you need to divide your gpm by the amount of nozzles you have to get the correct psi out of each one.

My ts2021 is 4.5 GPM with my 420cc chonda motor… I was told to use a 5.0 nozzle… That makes it 2500 psi… If I go with a 4.0 and up the psi will it harm my pump or unloader?

Why would you want to up the psi?

Just curious… I’m quite happy with what it does now … I have a GP 18" SC ith 2.5 nozzles seems to work well… I understand that volume is better I’m just curious and want to know… No harm in knowing and understanding capabilities

Hello. I was wondering if anyone could help me figure out the PSI I am applying to concrete with my surface cleaner. I run 8gpm, 200 ft. hose, two bar surface cleaner and my nozzles read 25055. Thanks in advance.

I like this calculator, easy to use and has a chart below it for quick reference.

Multiply your orifice size by the number of tips you have on your SC and plug that number into the appropriate box. Plug your gpm into the other box and your psi is calculated. 50-100 psi drop per 100’ of hose due to friction, depends on who you ask. Elbows, fittings, gun, etc will also affect pressure at the SC.

Easiest, and probably most accurate, way to figure that out would be with a pressure gauge right before the gun on your SC. Take your reading with the trigger pulled.

I am in the process of fine tuning my trailer purchase. I was going to put a pressure gauge at the outlet of the pumps. Being in the Fire Service we have gauges at the pump panel. The addition of the one at the SC would show you friction loss. It also shows residual pressure.

At idle my pump will be at the 4000psi but when the SC is in service it drops @2500psi. Being the system is new to me I am not sure if this is a standard working pressure and pressure drop.

The pressure is going to drop to whatever your tips put out (at your pump’s gpm). 2500 is a pretty good spot for a SC, I’d rather be too low than too high. Easier to pre/post treat than it is to fix etching.

Find a nozzle chart or an online calculator, it’ll help you figure out what all tips you need to buy. You’ll end up with a box full of tips you don’t use anyway, but the chart will still help you understand what you’re doing

You don’t need to keep the gauge on all the time, once you set the rig up it just stays put. These gauges aren’t terribly accurate anyway.

Old thread/quick question: So, the calculator shows at 5gpm the 25020 tips (2 = SC) should put out 6250psi each. On a 3,000psi machine that should not happen, so what does happen? Psi is about 3,000psi and flow is a bit restricted because of the smaller nozzle size (25020)?

On a 5gpm machine, 2 nozzles (SC) size 3 is what is called for for 5gpm and 3,000ish psi. So, does the move up to 25030 maintain the same 3,000psi and allow for full flow?

5 gpm going to 2 nozzles is 2.5 gpm each. 25025 would be stout. I’d probably go 25030. Either engine will stall or something else would have to give if the load isn’t manageable.

Generally speaking you want 2500psi on concrete.