Hi all, new to the community here. Looking around this is a great resource! I have a Craftsman 2.5 GPM 3000 PSI unit that worked fine. Lately I notice that using the soap tip or a tip on my jrod when letting off the wand the pump makes a screeching noise before the engine comes down to idle (engine automatically comes to idle when trigger is let off). It does not make that noise with any other tip (red, yellow, white). This is only the second season using it, any idea where I should start looking for an issue?

Welcome! I would try setting the unloader to see if that helps. You might end up having to rebuild the unloader.

Thanks for the quick reply! Why would that happen, it didn’t do it before? How do you set the unloaded? Can a pressure gauge be used to test to see if it in fact the unloaded? It’s a bizarre noise, best way to describe it is a screech.

Unloaders have moving parts, can wear out over time, or calcium deposits can build up on them. I would first take it apart and try and clean it. It should say in your manual how to properly set it but, before disassembly I would count the number of turns it takes to get it off so you can reset it back to the original setting. I’m not sure how to set an unloader on a homeowner machine. Post of picture of the pump and unloader and maybe we can figure it out.

Did the other tips come with the machine? You may be using the wrong size tips in the j rod. Could also very well be the unloader sticking

Thanks marinegrunt, i will take a pic tomorrow and post it. Firefighter for hire, tips did come with the unit, odd thing is the black tip soaper does it as well and it came with the unit. The jrod is new and is supposed to run with the down stream injector i bought. I was not running that when i noticed the noise. If it was in fact the unloader what the hell would make it screech like that?

When you say ‘idle’, is the machine dropping in rpm’s like with a car? Unless there’s some new-fangled stuff out there it’s supposed to stay at the same engine speed.

Yes, when u let off the wand on my machine it idles it down automatically

Frankly you can just replace that pump pretty cheap, I think they run about $100 or so.

If I have to I will. Is there a way to determine if the tips were the issue? In other words how to tell what tips should be used with what pump

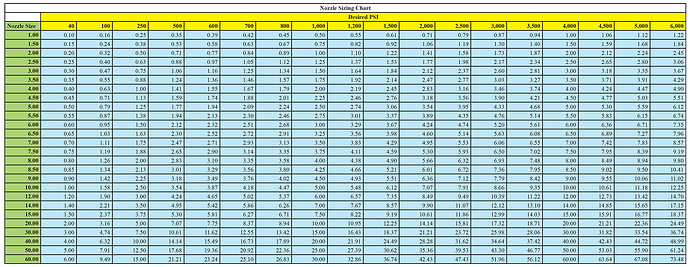

A little tough to see but this is a chart we use as professionals to get the desired PSI out of a nozzle.

So say you want to get around 3k psi, you’ll need a 3 orifice to achieve that. If it’s just a low pressure ‘soap’ tip, about 500 psi, then it’ll be a 7.

OK i understand, but how do i know when a tip is going to damage my pump? do i need to stay in a range accoring to spec of machine? can the wand become an issue? I use just the gun mostly no wand attached. I know i have a big box home owner machine right now but jeez i got it halfway through the season last year and it probably only has 5 hours on it this year.