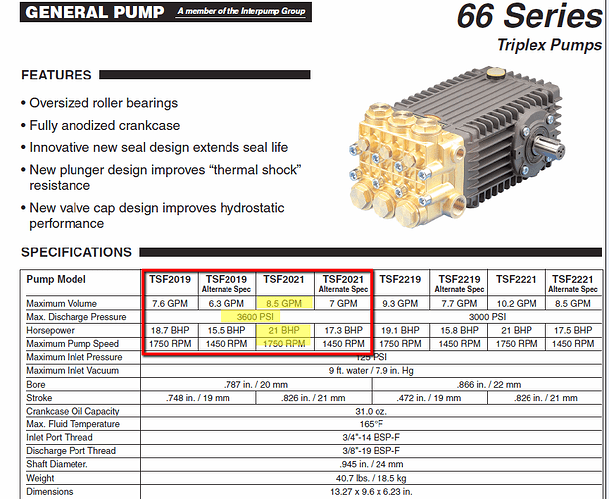

You can get 3600 psi but not 8 gpm. You can get either or but not both

Innocent bystander

I am not the one to even question. Just another example of what I don’t know. My sales invoice list my machine as Bandit Belt Drive, Heavy Duty Aluminum skid Mount 8GPM @ 3500 PSI, Honda GX690, Comet Premium Series Pump. That is the only reason I thought I had a 8GPM machine @ 3500 PSI.

I had a great idea one year to thread in my 2in hydrant hose to it so I could sit in the truck for 30 seconds while it filled lol

Big mistake, about blew up the tank it became so pressurized

No worries. Most of the internet vendors that are on the forums and round table routes are pretty sketchy and lie about specs.

You forget fine sir, I test everything. In fact, the last time I tested mine, about 4 months ago, it actually exceeded the specs, got 8.7gpm instead of 8.5gpm. Will try to shoot video if I get time this week.

I agree, but I believe this argument will go on for eternity. All 3 of my pumps/engines exceed the specs and the formula. I’ll see this week if the new one does the same.

I think the formula is a rough guideline, but definitely not exact. And just like most mechanical things, you can adjust the performance parameters.

Those numbers are based on electric motor not gas . If you go to udor site you will see the same pump with a 20bhp number will require 24 gas engine

Please send a video. About the only way to test pressure and gpm is with a pitot gauge. Lots of guys try to test it with a bucket lol

How are you testing to see if specs are met? Genuinely curious.

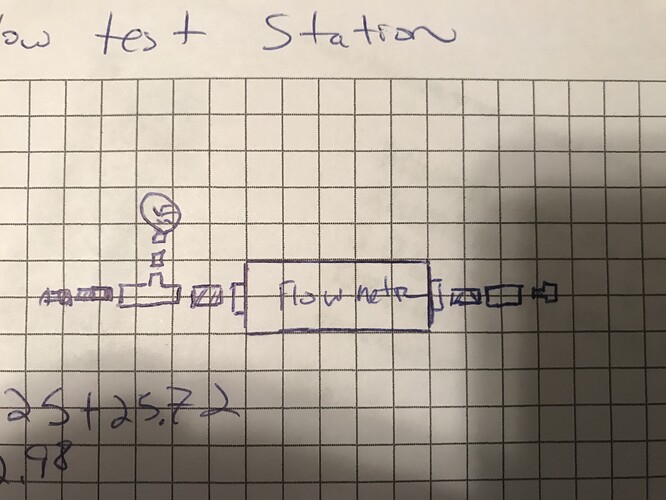

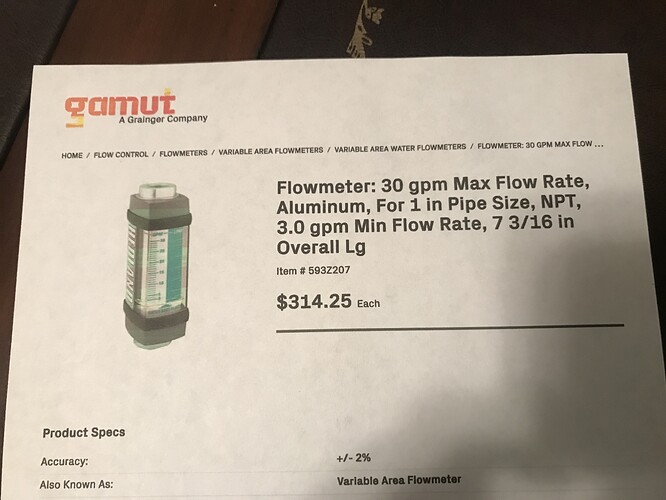

Please ignore my handwriting. It’s actually a medical condition. I also have this mocked up on autocad but I’m not around that atm so my original hand drawn copy will have to do. I have thought about setting up a little test station where my pressure hose off my reel quick connects into this then I can have a short maybe even 10’ whip hose after the fact to which I could hook to a surface cleaner, trigger guns, I could see what pressure loss I have with different trigger guns, different lengths of hose, added elbows just about anything but at a total cost of about $500 I don’t feel it’s worth doing since it truly doesn’t matter. This just seemed like a good opurtunity to share a small idea I had over a year ago. I have all the items already set up in high pressure stainless. Just never have pulled the trigger. It could tell me the true gpm and the exact pressure at the same time. https://youtu.be/ixa9zXOLXpM This video will show the basic idea. That’s where I saw it. (I just spent 10 mins looking for this video, your welcome ![]() )

)

You would not believe the number of people that put a gauge on their machine with a pressure tip, see it spike 3500, take out the tip and fill up 8 gallons of water in a Paul in one minute with a low pressure tip or no tip, and think they have 3500&8

I’m unclear of what people are meaning here?

To determine the maximum flow of the pump is easy.

Run the machine with no fittings on the pumps high pressure outlet, into a marked container and over one minute, it will give you what the pump is able to produce. Yes? No?

If you want to know what it has on the job/real world figure with a white tip, red tip or anything else - so long as the orifice matches the pumps GPM, it will be the same. (Hose length, diameter, fittings will make a difference somewhat).

So with this in mind - to get a true flow rate, wouldn’t you just run your machine with the ball valve fully open for one minute, and that’s what you get? (After all the hose and fittings) The correct tips shouldn’t make a difference to flow, only pressure?

The pressure for real world “should” be using a red tip I’ve heard - why? It’s the same flow rate and pressure, just zero angle.

Ok - correct me now

I want to learn too

What you described is what most people here do. Sure, it’s close and most folks don’t know or care that it isn’t true specs. 8@3500 means it is flowing 8gpm AND producing 3500 psi at the same time. Can’t be done with a Honda 690, which is kinda the standard on assembly line machines like pressure pro or BE

Ok, thanks

So it’s the engine, not the pump. The pump can do what it says - the engine doesn’t have the power.

And here I thought I had purchased the Mercedes. I’ve got a lot to learn!!

Nothing wrong with what you bought if it helps makes you successful. . Knowing the limitations of your equipment is important but doesn’t mean you can’t make plenty of money with it

I’d kill for your set up! It’s awesome (compared to mine!)

On a side note - the wood you used to mount the skid onto - I’d probably get some galvanised right angle to brace it. There’s a lot of weight in that engine and pump. When the wood gets wet over time, vibration etc - heavy braking might just send that forwards.

I put a bad mock up of a bracket in the pic. Use them either side maybe ![]()

I think they key to getting over spec results is turning a 1450 pump at 1750.

Just a thought, no facts lol

Look at the specs on the TSF 2221 pump on the right side of that chart I posted - 10.2 gpm at 1750 but only 3000psi. would be a heck of a hw pump. Also with that one, can get 8.5 at 3000psi with a gx630 running at 1450.