So, I’ve been opposed to these, mainly because of the problems my landa guy had pointed out. He has dropped briggs and kohler’s because of there issues. He just bought the last 40 gx690s he could find but the end is near unless trade restrictions are lifted and they can be brought in. So, today when I came back to the shop I found this with instructions to run it for a few months, give an honest assessment, then keep it or give it back if it sucks.

Looking forward to hearing what your experience is with it, I have two gx690s one with 1600 hrs on it so it might make it to the end of year but will buy an igx800 in a couple months as a backup if I hear they’re performing well.

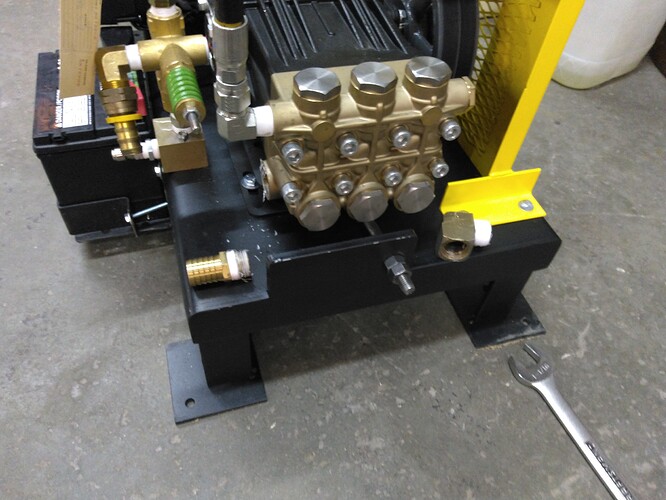

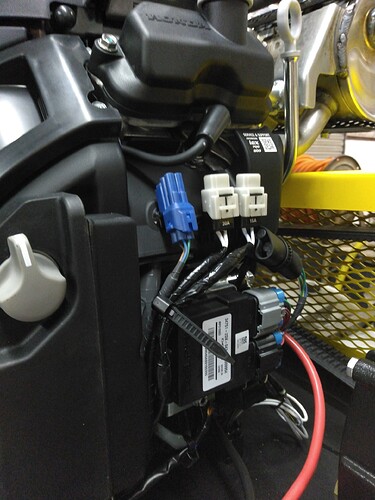

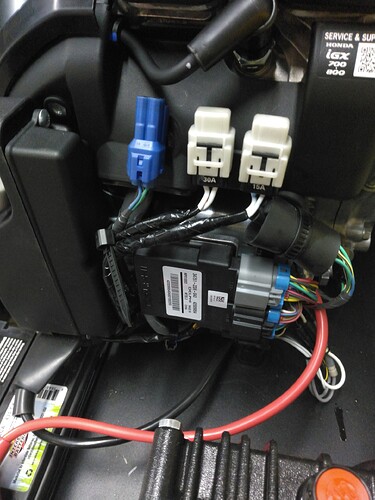

Your gx will easily give you 3k plus hours. He has covered all the connections with dielectric grease and I am going to put heat shrink on top of that. That is the biggest problem in the field.

Great… before long we will need a computer to diag small engines too

He had to get a laptop just for them for diagnosing

Why can’t it just be simple? Back to the good ol days when all you needed was a rock and screwdriver and you could limp it through.

Let’s go back to starting engines with a hand crank or better yet a 12g shotgun shell with the danger pellets taken out. Back when men were men

Still feel like a man, idk.

@Innocentbystander I am very interested in your review. Looks like this may be the future regardless if things don’t straighten out.

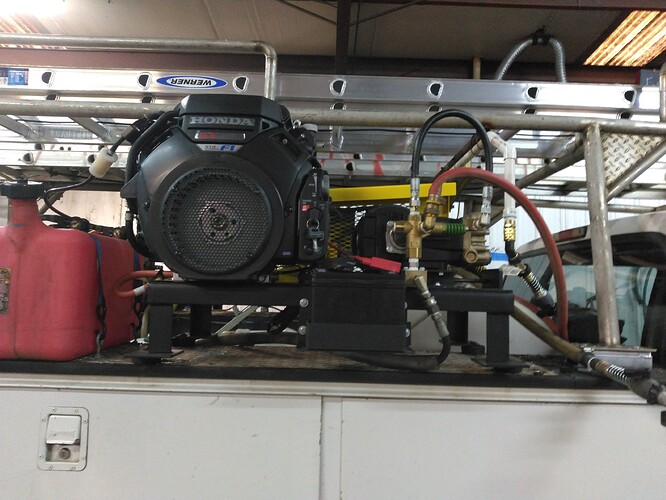

I got to cut the legs off a little bit for it to fit under my ladder rack and rig up a hoist to get one machine off the truck and get this one on. Maybe this weekend. I regret selling my forklift.

You will love it you ancient dinosaur lol, Thers not much to not like about the features they have other than the issues that haven’t popped up yet.

Regarding the diagnostics, if you have a buddy that’s in the marine industry they will be able to diagnose it as well, Honda outboards run the same DR.H diagnostic software as these engines, you can purchase bootlegged aftermarket versions on eBay for basic trouble shooting, if I remember correctly the LCD display throws up codes as well to lure you into the dealerships before the wallet comes out to tell you the spark plugs needs replacing.

Show us witch connectors were an issue and how you went about it.

Yalls cold machines are so little and cute. Like little toys. But easy to move

I’ll get pics in the morning

Cats with big hot boxes are just compensating

Everything is slathered in dielectric grease and I wrapped the bunch of connectors in a piece of rubber and a zip tie. Fingers crossed.

Expand on where your putting the dialectic grease, is it in the connectors themselves?

Yes, on them, around them, anything to keep water and bleach fumes out

This is how ppl must of felt when the 1st Henry ford rolled of the assembly line and drove down the street .

I have two 2015 EFI Kohler’s and while there have been a few problems (fuel pump on the 5.5, which has been redesigned now and I replaced a starter on the 8 GPM) they run great and work as designed BUT they do need diagnostic support when there is a problem, unless it’s obvious like what I described. They have lights that flash different sequences. I use battery terminal spray on the electrical connections, it runs into tight spaces and then gels up. Pretty easy to do it that way.