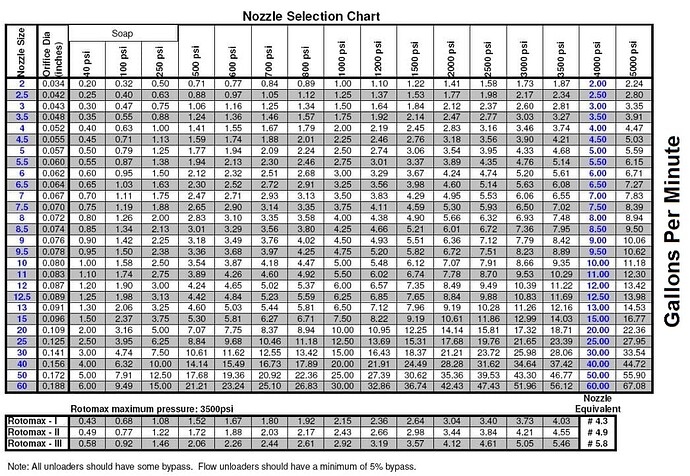

Hi everyone, I’ve been steadily getting my pressure washing business set up and was curious if anyone had good recommendations for what tips to use for my surface cleaner. I’m running it with a 4 gpm 4400 psi pw. SC is 18inch and has 3 nozzles to spray water, each being 25 degrees and 1.5 mm orifice size (So a total of 4.5 max nozzle size)

I absolutely do not want to etch concrete when I get my first customer, and according to my research, I’ll need to get between 2500-3000 PSI for residential flatwork to minimize damage.

My problem, however, is that I haven’t found any specific nozzle tips that will get my sc down to 2500, given that it has 3 nozzles and most SC’s have either 2 or 4.

Does anyone have any recommendations for nozzles or if the stock 25015’s it came with will be fine?

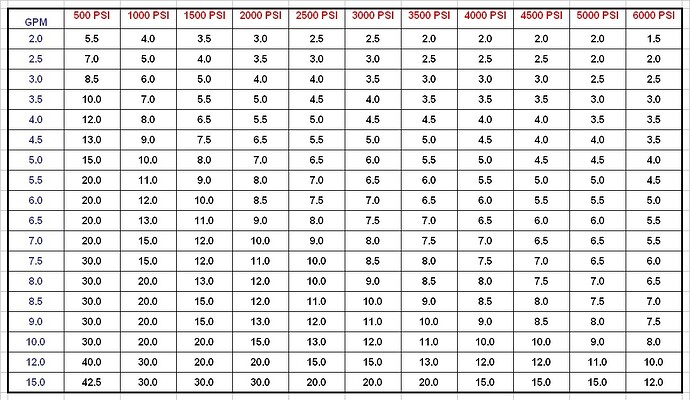

The guys on here gave me this calculator a few years ago so I’ll pass it on to you.

https://www.amazingmachinery.com/nozzle-calc.html

Best I can tell a 25015 is about right with three nozzles but let the other guys comment.

I will say however, if you see ANY evidence of the cream coming off or etching, just STOP and don’t keep going like a few others have done.

2 Likes

You’ll need to test the pressure at the gun. The chart is a good start, but not the law. I can tell you my 4gpm 4000 psi machine with two 2502 nozzles only puts out 3000 at the gun after 100ft of hose. Also, it’s not just the pressure that can get you in trouble, but also how close the nozzles are to the concrete. 2500 at 1” away is more dangerous than 3000 at 2”. I set my nozzles as far from the concrete as my surface cleaner allows. I’ve ran this setup for 4 years now and have never had a problem.

1 Like

The xx015s math right for a 3 nozzle setup, but like the others said, test to be sure. You may want to give a set of xx02s a try as well, depending on other factors.

I’m about three months too late to this thread, but am I right in thinking that you can’t just add up orifice diameters like that? If you have three nozzles with orifice diameters of 1.5mm then the area of each nozzle is 1.77 square mm or 5.31 square mm in total. That then works out to be an effective diameter of 2.6mm?

(Confirm that the orifice size that you are using is a diameter and not something else before taking my word for it, of course - I could be wrong!)

Don’t over complicate it by figuring sq. mm. Just take your flow rate and divide by how many nozzles you have, then use a nozzle sizing chart.

4 gpm / 3 nozzles is 1.33 gpm per nozzle. Use that 1.33 and a sizing chart to figure out what you want. Three 2502 nozzles for example will net you only around 1700 psi

2 Likes

Oh that’s a much easier way of working it out! I got too hung up on the size.