Robin1 I use the app for this forum and am not seeing the 10th comment. If you can, please pm me for clarity. Thank you

All-Flo Air Diaphragm Pump is a softwash chemical application pump. You can apply just about any Softwash or fleetwash or housewash chemical through these pumps with an excessively long lifespan.

For a good start 4gpm machine suits. You’ll do less seals etc. Bigger volume pumps need a buffer tank and automatic cut off sensor. Our machines over hear in that range are generally 4000 psi and run a 20 inch path cleaner using 025025 nozzles. That 025 orifice and 25 degree spray nozzle. Although you get a better result replacing the standard nozzles with specialty nozzles from the nozzle experts.

I have to get my Skype sorted and we will talk.

We adjust our unloaders depending on what the job is. With a new one we squeeze 5000 psi + for boat ramps etc and drop to 4200 psi for concrete. that’s for the surface cleaner.

We have long given up on the inline chemical injectors as they do not do SH and whether you flush them or not they do not last.

With a 4 gpm 4000 (±) psi go for .025 nozzles. Bit more water and still holds the pressure.

You love these JROD’s , why not get a decent power head and a long range nozzle.

Italian power/ turbo heads make the job so much quicker than fan nozzles.

Just trying to share what helps. Pete

Ah!!! Ok… The 4 at 4000 psi belt drive cold pressure washer was right around $1350 before the price increase on March 1. I haven’t seen the new prices. I think I have one unit left at the old price but not 100% sure. At the most, it is $1480 for the unit. It comes with 50’ of Grey high pressure hose, a 20% acid chemical injector, 5 colored nozzles, and a 3’ gun/wand assembly. If you are a giant, consider a 40-48” wand to prevent stress on your neck.The unit is supplied in either a skid or a cart for the SAME PRICE. The cart is aluminum and skid is powder-coated steel because the bases kept cracking.

If you have a cracked base, you can provide a picture of the serial number with the crack to your dealer for a new one.

The 16” or 19” Whisper Wash is a nice compliment to the 4 gpm pw. The 16” floating Ultra Clean is $405 and the 19” Classic is $595. Add the 6292 black handled ball valve and a 3/8 male couple and a 3/8 male plug to the buy to. Prevent extra miles walked on the job turning your pw on and off. If you fight your hose, install a live gun swivel before the ball valve such as the 3/8 JE Adams or the fancy Mosmatic. Never use the ball valve 1/2 open or half closed or with hot water beyond 176 degrees F or you will need to replace the valve prematurely.

I should mention… NEVER, EVER ADJUST YOUR UNLOADER unless you want to pay your local repair shop to replace your unloader, your pump, or spend money unnecessarily on your pressure washer. Your unloader should be set 200 psi above the operating pressure of your pump and meant to be left alone.

Use a 3/4” ID Garden Hose stripped entirely OFF the reel for best flow. Using any hose on the reel most often restricts and pinches the innermost layer and prevents flow.

Also, I’ve had a few guys ask for the 6’ sacrificial jump/whip hose at the end of the hose before the gun. If you add the extra hose, consider the fact that at 8 gpm, it will also add three complete sets of hose crimps and four hose quick connects plus two more o-rings. If you choose to reduce the flow by adding that extraneous length, use a 1/2” steel coupler to connect the “sacrificial lamb” and ask for a 1/2” mpt at the end of your 3/8” hose instead of the standard 3/8” mpt solid or swivel.

Never grab your high or low pressure hose by the very end. Grab the hose by at least a full arm length down and pull.

Don’t pull all the hose off the hose reel. Leave one single wrap to protect the crimp.

2500 psi doesn’t blow the top off a custard tart.

That’s about right. We have run 600 ft of 3/8 hose and ended up with 4000 psi at the pointy end. Starting with 5000 psi.

5.5 gpm Have a buffer tank with an automatic cut off if the water runs low. Saves thousands on pump rebuilds.

Tell that to the 18 trailers and 34 tractors I washed today by myself! They were a hot mess but 1700 psi at the gun gets it done everytime!

Forgive me Lori, That is crap if you have a decent commercial machine that has pressure dump valve. We run a VB350 as an unloader and change the pressure regularly depending on the job. We also have a VS??? as a master dump valve. The dump valve is set at 6000 psi.

Had them for years without problems. Broke a spring in an unloader once but the abilty to control the pressure for different jobs far outweighs the cost of a new one. We always carry spares for most things. We have spare pumps at the shed so we don’t get let down. ( 5.5 LPM 5000 psi ).

Those unloaders come with a plastic twist handle for easy adjusting.

It’s ok. I understand and respect your opinion. You can continue to pay the distributors lots of $$$$ when you play with the unloaders because it will lead to premature failure when you adjust them.

Keep your chemical injectors at least several feet away from your unloaders and never plumbed on the outlet. The chemical will back-siphon into the unloader/nipple.

We feel that you work harder than we do for your money and respect that fact. We don’t want you wasting any of your hard earned cash.

Injectors needed to be away from pump to straighten flow before injector. Has nothing to do with injector backfeeding into the unloader. That is a physical impossiblity.

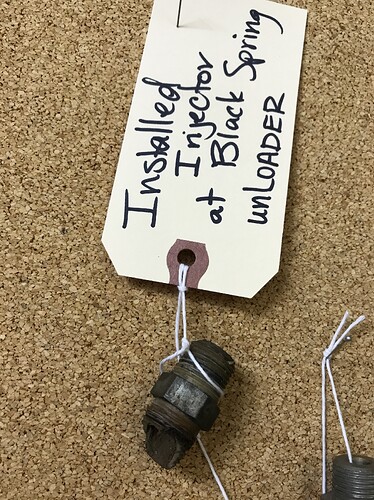

Really, look what it did to the nipple. Don’t run SH through your pressure lines as it does the same. Work with an X jet or you can get far cheaper acid venturi’s and make your own with a gun and 6 inches of wand. Works great and no need to go back to the unit if you want to rinse.

In ten years, I have bought one extra unloader. That was one where the spring broke and it was not adjustable. The ball wears out more than anything else. VB 350 uploaders are fully adjustable, maybe you should stock them .

If it works for you that’s awesome. We do to much work to x jet and deal with the pails, plus i prefer a low pressure wash. I’ve got a bucket of them though and they have their place once in awhile

Just getting that best orifice size and tips is the trick. Whatever works is good. We have a lot more hard surface cleaning over here. So try and get best bang for buck with venturis at the short gun.

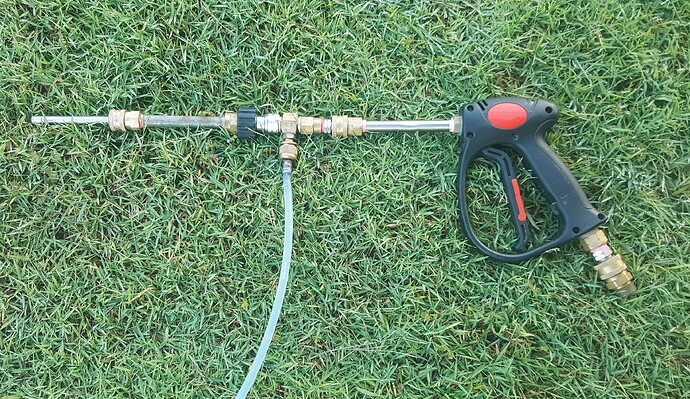

Let’s see your Venturi!?!

That one has m 22 and QC fittings so it’s interchangeable with anything i want to put on.

That’s just a ladder saver nozzle but you can play with any size nozzle to effect flow rate.

If you need more distance you can plug in another section of wand. I threaded stainless at whatever length I need.

That works perfect for doing buildings and is easy to change the gun with a valve on the end of the pressure line.

Hope that gives someone an idea to save them time.

We have foamers and other toys for different jobs but that’s my favorite.