Hey, Newbie here

Im located in Australia and starting a pressure washing business! (I have wanted to run my own business for a long time, I currently have a physical outdoor job and am well aware of what im getting into. I will be doing residential flatwork and house washes to start)

I have a 5gmp 3000psi Honda belt drive and Comet pump and a 20’’ Whirlaway surface cleaner.

( Im hoping this SC wont be too slow based off the 4gmp per inch formula).

Setup will all be on the back of a Dual cab ute.

I am currently working through the plumbing, the guy at the PW shop told me ¾” plumbing would be fine. Based of what I have read on this forum its better to go for 1”.

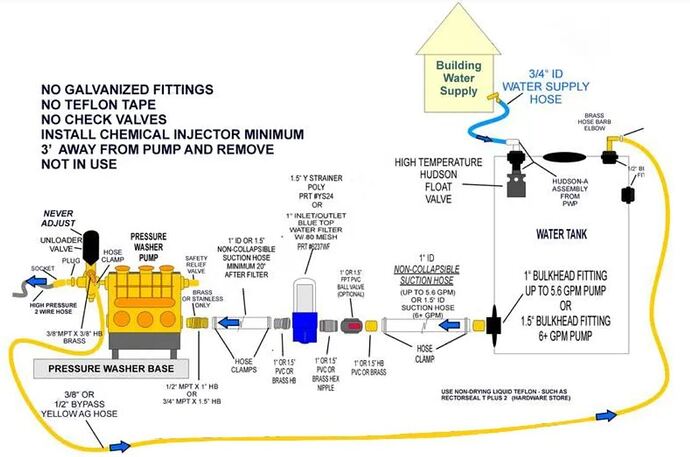

My current plumbing plan is based off the Texas pressure washing. com diagram

- Everything will be 1’’ non collapsible hose ( I may need to go down to a ¾” hose between filter and pump depending on what fittings I can find to get down to ½’’ pump inlet)

- Downstream injector with QCs off the unloader (eventually a DS bypass once I make some money)

- ½’’ Bypass hose from unloader to buffer tank

- PVC hose barbs except for Brass on the pump

- Camlocks on water supply to buffer tank

My problem is that this is also our recreational vehicle so I need to take all the equipment off approx once a month for camping trips.

- Any suggestions on what fittings to use adjacent to the buffer tank and pump so that I can separate the plumbing line without wrestling with hose barbs every time? (I was thinking camlocks but have read they are no good on a suction line)

- Banjo is the only decent water filter I have been able to find in Australia, I believe it’s a NPT thread whereas everything else I have is BSP (Banjo hose barbs are out of stock everywhere) not ideal but can I just smush them together with some thread tape and hope for the best?

Thanks in advance!!