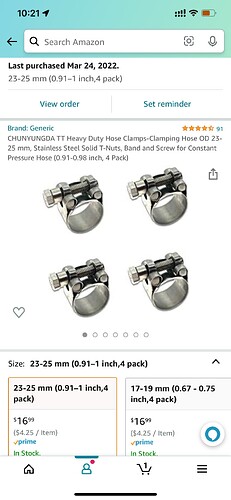

I just changed a bunch of hose clamps from the worm style to the t-bolt styles. The worms mess hoses up and don’t have anywhere near the holding power. But I’ve had the hose blow off a couple times already in one day and only 190 psi. Aren’t these supposed to be way better? I know they have tight tolerances and need to be specific for the hose size, and I’m pretty sure I used the correct ones. Maybe I didn’t tighten it enough the first time for fear of breaking something. Anyone use these with great success? They look really nice and well built, wide and sturdy…

Overkill Sean. Throw a set of pinch clamps in your lunchbox, low profile, stainless, takes 30 seconds. And the best part they still work with rusty dedicated truck pliers.

Something must be off. You seem to be having a ton of problems. I’ve never had a hose blow off on the AR. Are you sure you’re using the right sized barb fitting to match the hose?

How do you release those?

They sell a fancy Apollo removal tool, but you can stick a flat head screwdriver in and wiggle it to pop the locking tabs.

I just grab the pinch buckle with a pair of pliers on the sides and twist it back and forth a few times…either the tab pops loose, or the buckle opens up enough to wiggle them off the hose. I do use 2 or 3 on every important (read SH) connection though. I’ve found where 1 of them has worked loose, but the hose has never popped off. They’re way more “hand friendly” than worm clamps too, in places like garden hose ends, etc.

I got two sizes that are right next to each other. The bigger of the two is the only one I couldn get to even go around it. I’m pretty sure that I didn’t torque it down enough. These things have a tremendous amount of clamping power and I didn’t want to mess something up. Since I clamped it all the way down I have not had an issue, yet.

Thanks man I’m going to get some of these, especially for where the hose connects inside the reel. I didn’t like how there was a bolt head sticking out when rolling it back on, looked like a pinch Point to spring leaks

Just as @Innocentbystander said. Insert flathead and twist to loosen, then just twist the hose out, if re Attaching, cut an inch of hose off and start again. They’re great things racer, used in many OEM applications.

I’m sure, but I’ve never had just a standard one blow off so will probably never use. Was just curious.

Here’s the video I watched about them that was pretty informative The Best Hose Clamps/ T-Bolt VS. Worm-Drive - YouTube

On that note, @MuscleMyHustle i just ordered pinch clamps and the crimper. Those do look nice plus low profile. I’ve had problems with worms cutting into the hose at the reel and I want them at the gun end too.

There’s nothing inherently wrong with T-Bolt style clamps, I use them all the time on intercooler piping when I’m doing an engine build and can’t get genuine motorsports wiggins clamps or they’re out of stock, they’re good things, just a bit overkill for what we do. Don’t take it the wrong way they work! Just neater and easier options. Give the pinch clamps a try and see how you like them.

The worm drive clamps are rubbish. Throw them straight in the bin. They’re for hobbies.

@Racer Yeah! But you have all the tricks of the trade up your sleeve! Let us less experienced folks play around with some clamps ![]()

![]()

Yep, we put all pinch clamps on in-house…I just keep the spare parts bin on each truck stocked with a few worm clamps so they can make a field repair/change if needed to get through the day.

I feel like I must be doing something wrong, I’ve never had one come off or blown a hose off. Feel left out of the cool kids club, lol.