It’s no longer winter here in Canada (pretty mild this year anyway) and I’m just about ready to get back into washing - as long as I don’t get shut down by being classified as a non-essential business

Before I do my first jobs of 2020 I’m trying to fix an issue I had last year.

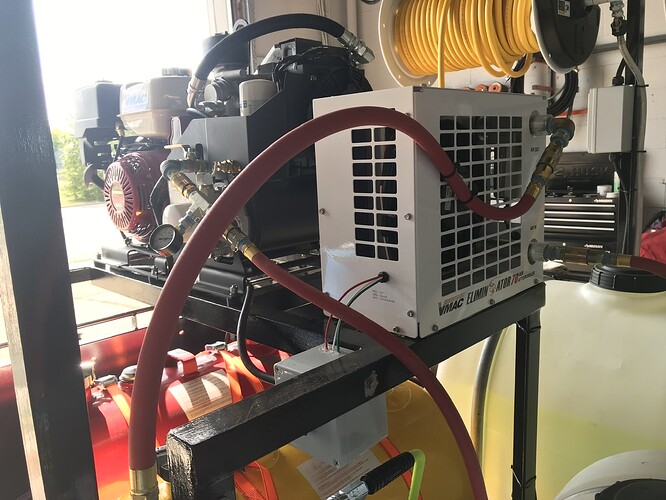

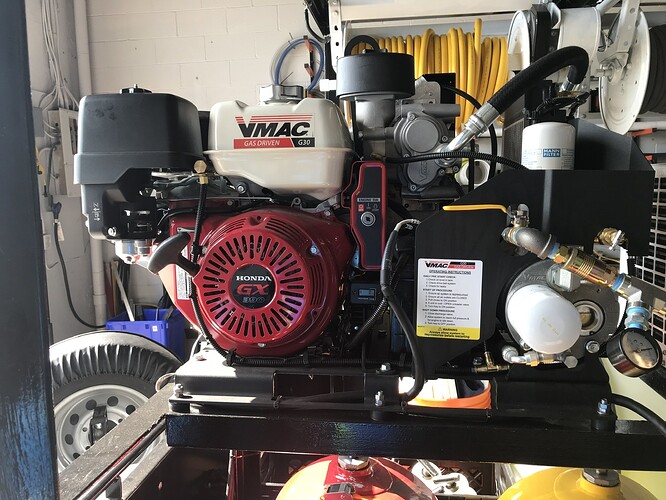

On my wash trailer, I have an gas engine powered air compressor that powers an air manifold pump - used for custom and high concentration chemical mixes for roof wash, concrete treatment, etc.

On the trailer the air compressor is mounted up high on the trailer (there’s no other space to mount it). This makes is awkward to refuel the small onboard tank.

My trailer does already have a 20 gallon fuel tank located underneath the spot that the air compressor is mounted - this tank is used by my gas engine pressure washers (that already have built in fuel pumps) and works great.

My challenge is that the engine on my air compressor is a Honda GX390 that gravity feeds fuel from a small onboard tank and doesn’t have a built in fuel pump so that I can draw from the large trailer mounted tank.

I’m hoping to convert the Honda GX390 to receive fuel from the large tank.

I’ve done some research and it looks like there’s a mod used for go-karts and golf carts that uses some sort of pulsed fuel pump to feed the engine.

My problem is that I’m not really an engine guy and don’t know exactly what I need to buy and how to install.

I haven’t found anyone local who can do the work so I’m wondering if anyone here has experience with this and is willing to provide some instruction/information?

This was just discussed in part on another thread. Either get your pulse from a barb installedb on valvecover or use a carb spacer with barb for pulse insalled on it. Use the briggs pulse pump, should be same as honda gx630 690 610… i found a cheaper manuf made by walbro. Ive yet to really use it tho.

Do you have a link to the other thread - or the name of that thread?

Briggs and Stratton 808656 or equivalent should suffice if you are able to connect the pulse pump to the vacuum line from the OHV cover. Note, Honda does make several variations of the fuel pump that usually equate to different orientation of the 2 or 3 barb fittings .

Thread is recent named “A big thanks” by DcBrock

From what I’ve read, the pulse pumps are hit or miss. Some people have great luck with them, and others have issues. I bought a 2.5-4 psi 12v fuel pump from Amazon and a 1-5 psi regulator and ran a new line to the carb. I tested it briefly and it worked no problem, setting the regulator at 1.5 psi. I’m not sure if it’ll end up causing me issues in the long run, but so far so good, and if it ever fails, I can just disconnect the pump hose and reconnect the fuel hose from the gas tank on the motor.

1 Like

I’l try and post some pictures later but I’ve done both the carb spacer with hose barb and the valve cover with hose barb. I installed an 18 hp engine in our golf cart and used the carb spacer. I have a 16 hp Vanguard where I installed it on the valve cover. Both work great. Your issue might end up being the amount of drop. I don’t think you’ll have a problem with 3’ but, if you do, I’d go with the electric fuel pump with regulator that was recommended.

1 Like

The only way to do it properly for long term reliability is to convert it to fuel injection. These are the kits that they use for bored out GX390’s to be able to manage load compensation on small performance engines such as go kart applications etc, it’s easily adapted to a factory GX390 if your just wanting a remote fuel supply. Everything that the new iGX Honda series engines can do this kit will be able to do also including returning to idle when the trigger is off for fuel economy/noise issues

The ECU software functionalities:

Charge detection and prediction

Fuel injection duration and timing controls

Spark angle controls

Air-fuel ratio close-loop controls

Fuel pump controls

Idle speed controls

EVAP emission controls

Transient fuel compensations

Decel-fuel-cut-off

Altitude compensations

Temperature compensations (winter, summer, etc.)

Engine protections

Diagnostics and serial communications.

I’m glad I’m not having any problens at the moment, i want nothing to do with efi.

It’s not something I would bother with either on a 13hp motor but options are available, refuelling with a can is just part of the operation. Some of these rigs are more to do with the design and layout rather than fuelling burdens. This whole problem can be fixed with a simple 12v pump instead of the air system.

I’ve got/had a fuel pump on my ch20, don’t want to mess with it is all so took it off. But.thats just me. Plus it gets super hot here.

@fhpressurewashing do you have any pics of the install?

Here ya’ go. Keep in mind that at this point, I’ve only quickly put it together to check that it would work, but it should give you an idea.

1 Like

They make low pressure fuelpumps for mowers, no need for regulator I would assume.

It could be fine, but I’ve read that the carb could flood if the pressure exceeds 2psi, so I figured I’d be safe and have the option of adjusting the pressure.

1 Like

I found some 1-2psi pumps, and based on your info Im gonna try them just for fun, and hopefully it works too. Ive got a 16gal tank it can sip from.

1 Like