Since the gear drive basically splits the engine rpm in half, the gear drive is best for 1750rpm pumps. the udor is specified for 1450 rpm.

Is everybody getting better then what the specs are for this pump? it would be at least another gallon per minute I’d say.

If you gear drive a 1450 rpm / 8 gpm pump, you should be able to get up to 9.6 or 9.7 gpm as long as your engine can handle the load.

in hoping that’s not why people were having pump failure/ problems.

Well, all this equipment is doomed to break down anyway but overworking the pump surely couldn’t help. My underpowered engine is probably helping lengthen the life of my pump by lowering max psi output.

Lowering engine rpms to around 3,155 should put you right at where a 1450 rpm pump is specified to run on a 2.176:1 reduced drive. But remember unless your running a diesel engine you’re losing hp by reducing your engine rpms. If you can’t make the power to run the gpm at the max psi of the pump you simply never had the right engine from the get.

I ran 18hp engines at 2580

You got me thinking now! If you buy a engine with a gear drive pump on it mounted to a baseplate and they never touched the rpms on it and it’s running flat out what in the world did you pay all that money for??

there’s pumps that are 1750rpm specd and 1450 rpm specs,

udor doesn’t have a spec of the 1750rpm. I’d they are as good as the previous versions(gkc is now ckc) I should be good.

I was talking about Udor

udor offers the great drive, but sources don’t change. it’s only $35 extra for udor 8gpm over the tsf2021., but the tsf at 1750rpm is 8gpm.

Bumping this thread because I’m working through this and could use some input.

I just set up a Udor CD series pump (1750 RPM) with a Udor 5119.H3 gearbox (2.176:1 ratio). With my engine spinning at 3800 RPM, the gearbox should be reducing the pump speed to around 1750 RPM… so far, so good.

However, after two bucket tests, I’m getting nearly 1 GPM more than the pump’s rated flow. I understand that overspinning a pump (like a 1450 when run at 3600) will increases flow, but a 1750 RPM pump running at its rated speed shouldn’t be able to exceed its spec, right?

Right now, my pressure gauge shows 2500 PSI at the end of 200 feet of hose… 500 PSI below the pump’s max. My thought is that by lowering the engine RPM closer to 3600 (which should improve longevity, move closer to peak torque to make better use of the HP, and theoretically reduce GPM if the pump is slightly overspinning) would help “recover” the missing PSI.

My calculations suggest my engine should be close, but slightly under, what’s needed to hit the pump’s rated GPM and PSI, yet real-world results aren’t lining up. I also realize my tach, pressure gauge, or math could be off, which might explain the discrepancies. Does this logic check out?

Throttling down your engine won’t increase torque. If you want less flow, that would be the unloader’s job. If it were me… roll out all 200 feet, attach the highest pressure nozzle you plan to use and open the unloader until you get a drip at the bypass, the unloader is wide open, or the engine stalls. Send it.

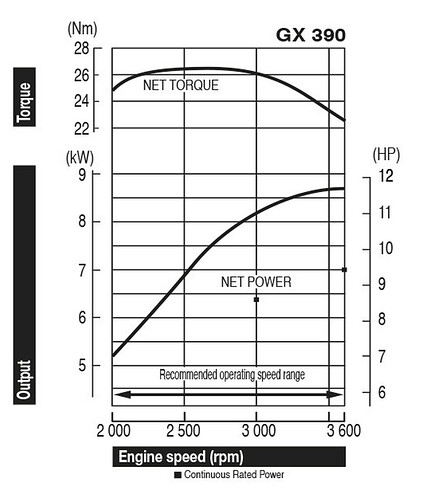

I thought adjusting engine RPMs affected both horsepower and torque. On an OHV engine, peak torque is typically reached around 2,500 RPM, while peak horsepower occurs at 3,600 RPM. Looking at the power curve for a GX390, if you run at 3,000 RPM (as opposed to 3,600) the results are a slight HP loss (0.7 HP) but almost 1.5 ft-lbs of torque is gained. Wouldn’t the same hold true of going from 3,800 to 3,600 or adjusting from any other RPM?

With 200 feet of hose, a 3000 PSI nozzle, and the unloader fully bottomed out, I’m only getting 2500 PSI, but the engine isn’t struggling and is producing nearly 1 GPM more flow. Even though GPM is king, I would rather not sacrifice the longevity of the pump or engine by overspinning it to get there… I’ve got everything packed back up since we are getting a cold front passing through next week… but will plan to tinker around and see what adjustments do.

That torque curve is probably wide open under a heavy load with the governor hard at work. Increasing torque by cutting the fuel supply doesn’t add up. What’s your gpm?

Peak torque happens at 2500 RPM, it’s not wide open and is only 80% of the engine’s workload. If you run it faster or slower than that, you’re not getting peak torque. Same deal with horsepower… drop below 3600 RPM, and you’re making less of it. There’s always a trade-off, where gains in one area mean losses elsewhere, plus the addition of possible wear and tear from not running wide open.

Not sure what “increasing torque by cutting fuel supply” is supposed to mean in this case.

The pump is rated at 7 GPM / 2900 PSI at 1750 RPM. I’m getting 7.9 GPM and 2500 PSI spinning (based on my tach) at 3800 RPM (again 3800 divided by 2.176 is 1746… so close enough). We know that spinning a pump faster than its rated RPM is going to increase the water flow (1450 RPM pumps using 2:1 ratios (pulley or gear) running at 3600 RPM always put out more GPM then spec).

I want to avoid overworking the pump or engine, so by reducing the RPM… at least setting it at the point where I’m getting a 7 GPM flow… the pump won’t spin faster than necessary or recommended, preventing undue stress. Once that’s dialed in, the reduced flow should allow the engine, assuming it has the capacity, to generate more PSI and reach the 2900 spec.

Thats at least my understanding based on what I’ve read… however if that logic is out of line or if there is some data out there saying otherwise, I’d be curious to read it. I will have to do some more tweaking once the weather warms up. My plan is as of now is to rerun the bucket test and see if reducing RPM will impact flow enough to only get 7 GPM… then adjust unloader and see if PSI can be reached.

@OhioFloMo Something you’re not seeing is you’re producing much more psi already that you’re not seeing at the gun. It’s showing up at the pump! You’re likely already exceeding the max psi allowed.

Correct, I set the unloader while the pressure gauge is on it to not exceed the pumps rating… then move the gauge to the end of gun and take a reading. More so out of curiosity then anything else. Regardless all of this became a moot point for me since I just moved to a GX630.