How’s it going guys? My name is Justin, I have a small business in the South Florida area pressure cleaning and soft washing. I am new to blend manifolds and proportioners but have been in the equipment side of this industry for quite some time now. Previously I was batch mixing with Slo-Mo surfactant and the results were great and it seemed to work well. After converting to a blend manifold it does not seem to be working properly and I am going through waaaaay too much surfactant. I am running a small 12v Flojet pump, specs are 45psi @ 3.7GPM. I am aware most of you are running 5-7GPM pumps and I know im probably going to get a lot crap for running a small pump lol. I didn’t like how much run off I was getting using the larger pumps and switched back to my small pump after trying them out. Anyhow, after reading the directions on PWP’s website, doing more then enough research and asking everybody I know I still cannot find my answer. I will attach a photo of how my truck is setup but it goes like this; (2) 1/2" lines (one from water tank to manifold and the other from chem tank to manifold) as well as (1) 1/4" line just for surfactant to manifold. Following the directions to mix 64 ounces of Slo-Mo with 5 gallons of water and only setting my dial on the soap to 5% open I am using that entire 5 gallon bucket of surfactant (64 ounces) to a 100 gallon mix. Again, my dial is not all the way open, not half way open and not even a quarter of the way open. Do I need to mix less in the bucket? Is anyone else using a system similar to mine that can chime in how much surfactant they mix to a 5 gallon bucket of water and how much they go through after spraying a 100 gallon mix? Any help would be greatly appreciated, I love this product but something cant be right here. Thanks for the help!

To get any degree of accuracy out of these proportioners you need to start out with the proper ball valves, yours look to be just plain old on/off valves witch work a little different to what your really trying to achieve with a proportioner. Study the picture below and ask yourself why it’s designed the way that it is.

And before the fluid dynamics engineers on here say his manifold will work fine, I know it will I’m just saying there’s better ways to “meter”

Hey man! Thank you for the reply, couldn’t agree with you more and its funny you mention these because I saw these right after I purchased mine and figured once mine started leaking I would convert to these. Do you run Slo-mo surfactant? If so, how much do you go through per batch and how much are you mixing per 5 gallon bucket? Also, couldn’t help but to notice the motor in your photo. Is that an LQ4 with a big single? Looking forward to speaking with you more, thanks again for the help!

Thread just started and it’s derailed, I like money so I downstream with an injector 95% of the time. Built LS3 block with a Garrett, 1400hp on lowish boost and an unusable amount of torque With any tire. Wel talk about it some other time  . Thread derailing has been heavy recently lol.

. Thread derailing has been heavy recently lol.

I see, im familiar with similar setups and sorry for the derailing im a car guy if you couldn’t tell

anybody else have any input on this?

anybody else have any input on this?

That’s definitely not you typical ball valve. Never really thought about it that way. so that one allows more control of flow and less resistance because of the way that ball is designed ?

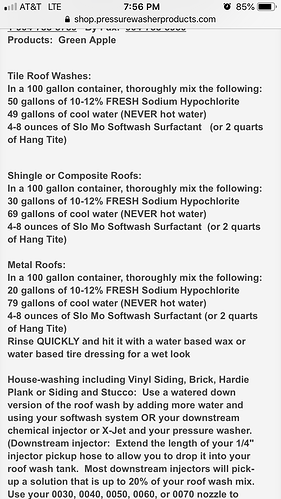

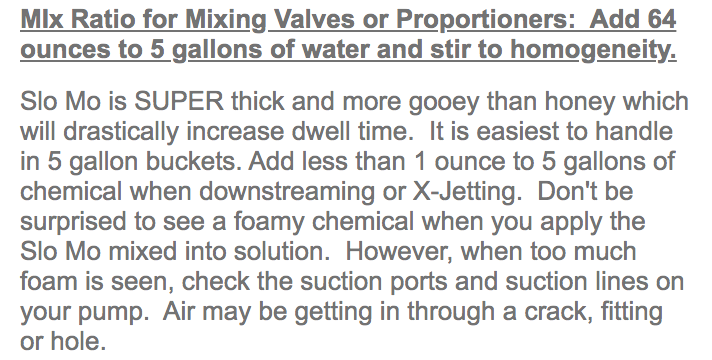

Seems like you’re using way too much but i dont know much about the blend manifolds. This is off pwp’s site

4-8 oz per 100 gallons is im reading this right for batch mixing. Where did you get the 64 oz to 5 gallons of water from? I see that for mixing Hang Tite but not slow mo.

So this is not a wise decision? @MuscleMyHustle

Not saying I would buy one just wondering for future thoughts.

Hey man! Definitely using waaaay too much surfactant, no doubt about that. Just dont know how much other people are mixing per 5 gallons and how much they’re actually using after spraying say 100 gallons of a mix. Here is where it says on the site about the amount per 5.

I wouldn’t say its a bad decision especially if your going from batch mixing to this but having said that if your looking for very precise numbers the GF metering valves musclemyhustle referred to would definitely be the better choice.

I used these in the oilfield and seriously looking into them to achieve the same as that valve. But with more precise control and the option to actually see how much is flowing. Still researching them at the moment. They held up for chemical injection on surface drive wells, and a test trailer I built 15yrs ago for testing progressive cavity pumps. Only broke one in all those years and that was from a 36” pipe wrench hitting it.

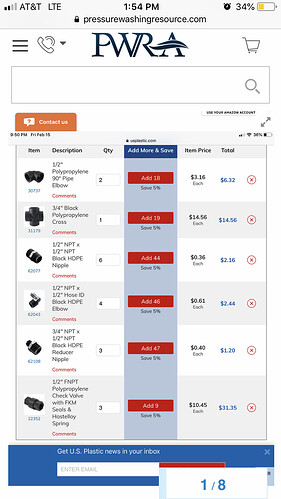

I think that thing is a bad idea. You can order all the parts from us plastics and assemble one for less than half for what that cost! There’s a thread on here with a complete list

Those flow guages are quite accurate and highly durable to truck soaps and acids, Hydrochem uses them on their 2 step gun systems.

I can’t see $400 in value, my son could assemble that unit after school with his pocket money.

They are durable that’s for sure. Put them through crap in the oilfield. They are relatively inexpensive versus that gf metering valve. They start around $40 and go up depending on accessories and model.

Spot on

Sorry what I meant was I didn’t think that setup was a bad setup, I assembled mine for about $160 if I remember correctly sourcing parts from different distributors. Ill have to look at that acrylic flow meter, im having a hard time right now with actually knowing 100% where my ratio is. That would be perfect it seems.

If I’m following you correctly, Have you’ve done a ratio test on your machine ?

Well, sort of. What I did was pretty simple, matched both tanks to the same amount of fluid in each and then checked them both after an hour of spraying. I have looked into sodium hyperchlorite test kits, strips, all sorts of scientific ways to test the percentage in water, gpm flow meter that run inline, etc. This was the only way I could actually say ok, this tank is pulling this much and this tank is pulling that much if that makes any sense. Out of the hose I should be spraying 6-6.5% considering my SH is 13% where I get it from.