Oh yeah, gotta turn it upside down & pour out all the gas… Just kidding, pull the plug & let it drain (oil that is, black gold, Texas tea). It’s best if the engine is a little warm but I drain mine cold all the time. Take the dipstick out first to help it drain quicker.

There should be a drain plug on the GX390 that allows you to drain the engine oil. No need to empty fuel tank. If you find yourself draining oil out of the little threaded opening where the plastic dipstick is you can still tilt the engine slightly without any concerns of fuel going somewhere it shouldn’t as long as it’s a Honda OEM fuel tank. You may want to consider spending about $15 and getting an oil siphon (hand powered) from a local auto parts store, or even a box box store and that’ll allow you to get most of the oil out just fine.

Yeah I was actually thinking of tilting it so it can just come out of the dipstick hole and make less mess but that oil siphon is a great idea. Thanks!

That’s different, you have a wet clutch so it takes a very specific oil for the clutch pack friction coefficient.

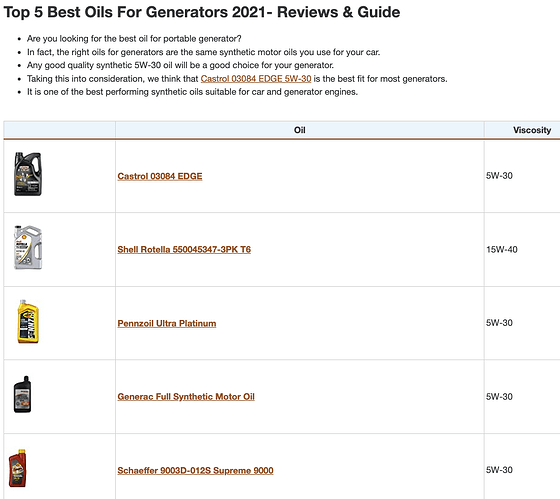

You are correct, most bikes except ducati’s generally have a wet clutch. But oils are not intended only for wet clutch applications and cannot be used for others. It’s simply some oils have additional additives that warrant the JASO-MA rating which just informs consumers it is safe for wet clutches. In terms of using Shell Rotella in a Honda GX engine, I probably will as I’ve had great results with it thus far. Specifically for small engine application, it ranks very well consistently, and its reasonably priced.

Unfortunately they don’t have that one in UK, looks good price too on tractor supply.

Guys can I check with you that this oil is okay to use for my Honda GX390 pressure washer - https://www.amazon.co.uk/Castrol-15042E-Power-Engine-10W-30/dp/B0064YM5PO/ref=cm_cr_arp_d_product_top?ie=UTF8

Thanks a lot!

Look at all the gear heads in this forum! Good stuff.

@Synthetic A GX390 has a reputation for being bulletproof. Just my 3 cents, as long as you are using 10w 30 ‘small engine oil’, send it! I run synthetic, mainly because I bought my engine used with a few years on it.

Fantastic, I went ahead and bought it, ignited on second pull and no smoke whoopee ;p

Now my next issue is can I change the lance without stopping the engine from running? I wanted to change the high pressure hose from my turbo lance into the surface cleaner so I stopped the engine after running it for about 30 mins and I tried to switch it back on after 2 mins of having it turned off. It wouldn’t turn on, I pulled at least 15-20 times. I decided to give it an hour before I tried again (I disconnected everything and reconnected all the hoses again) and then it turned back on thankfully.

Is there a time window before I can turn on the engine again after having it on for a while?

Short answer = no. An engine should be able to restart anytime. After running it for just a moment or two and then cutting it off, you should no longer need to have choke lever engaged in order to restart. Under no circumstances should you have to pull the rope more than 3-5 times with the choke on.

Put a quick connect on the end of your gun. Then you can switch wands, plug in your surface cleaner etc.

Why would anyone do it any other way… lol

Allows to havea spare gun just in case, quick changes of whatever you need. Worst problem it creates is another o-ring to change once in a while…

My brother in law won’t try downstreaming because he will have to change o rings more often and he will ruin his hose and connections.

Tried to explain multiple times how much time it saves

You guys are awesome, thanks a lot for your responses.

I will have to test that out again but I think I may have tried pulling the cord the second time with the choke off but the cord just gets stuck and won’t let me pull it without the choke on.

That’s because you didn’t relieve the pressure at the gun. Let the pressure off and the engine should turn over easier.

For changing wands, or to a surface cleaner, I use a ball valve at the end of my hose. I turn the ball valve off, relieve the pressure by pulling the trigger and then I can remove the wand with the quick disconnect and switch to the surface cleaner or another wand. The ball valve allows you to stop the pressure (engine still running) and squeezing the trigger relieves the pressure between the ball valve and the gun so you can swap devices (surface cleaner or another gun)

There is something not right then.

It’ll either be in your technique or in the machine itself.

As far as technique, be sure that you are shutting down the machine with the trigger on the gun pulled. This allows cool water from the spigot/buffer to continue to push the hot water out of the pump at a small trickle. If your drop stick/siphon tube is in a soap bucket it’ll want to pull that, so just simply pull drop stick and set it in a bucket of clean water (this also allows you to flush out the downstream injector giving it a longer life expectancy). Also, be sure to be pulling the trigger on the gun while you are attempting to start the engine.

Regarding the machine being at fault, it could be that the machine is hydra-locking. This is when the fuel system shut-off is not working as it should (whether it’s an electronic fuel solenoid, needle and seat, etc) and therefore allows fuel to flood the cylinder sleeve, making it nearly impossible to pull. And another tip is to slowly pull the rope out of the engine just a few inches until you feel resistance (compression stroke), then give it a quick pull to start. This will help prevent the rope’s pull handle from being jerked out of your hand.

SMH…

You may shake that head all you want. He asked a question about his machine and I’ve provided an answer for him that isn’t just that he’s using the wrong equipment. I’m not defending his equipment purchase choices, but simply trying to help him where he’s at right now.

So I tried again today, started up on the 3rd try and engine ran for about 45 mins. I turned it off, pulled the trigger on the gun to release the pressure. Came back to it about after about 2 hours, left everything plugged in except the suction pipe, that one i disconnected straight after turning off the engine, so plugged it back in, pressed the trigger on gun again to release any pressure.

Before pulling I made sure to have fuel on, choke on, switch on and valve open, suction in water. Pulled about 7 times every other pull the cord seems to get stuck and sometimes even pulls back hard. I was trying to turn on the engine so I could softwash the hypo I just placed on the patio. I had to pack up and go home after trying so many times to start it, I just don’t understand what is going wrong ![]()

I also need to find someone local who can look into it I think. Oh I am wondering also, is there a fuel minimum I should have in the tank? I only had about 1 litre left in tank.