Hi,

Im new here so be gentle please, i want to build a drain jetter and have a harben 6 cylinder pump, not sure of spec as no label or plate but was told 4000psi and 8gpm, does that sound about right?. I also have a yanmar 3tne 74 diesel rated at 23.5 bhp, the pump came off a petter 20bhp diesel and comes with drive coupling and bellhousing direct drive no gearbox, should i try to adapt this to fit my engine or remotely mount it via pulleys or shaft.

Neil

You may end up getting someone to reply here but there isnt much talk about sewer jetting on this site or many people with diesel engines

@Thom might be able to give some input. @florida_condo_cleani any thoughts?

What does the flywheel side look like on the yanmar?

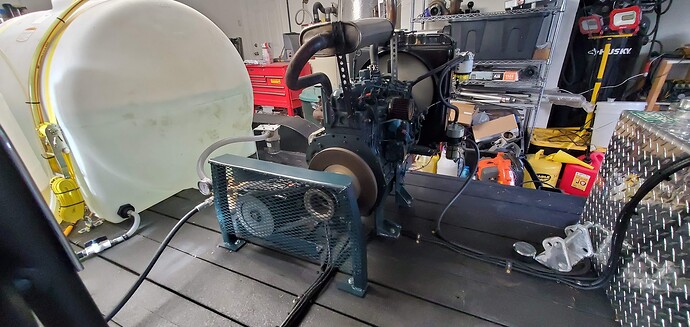

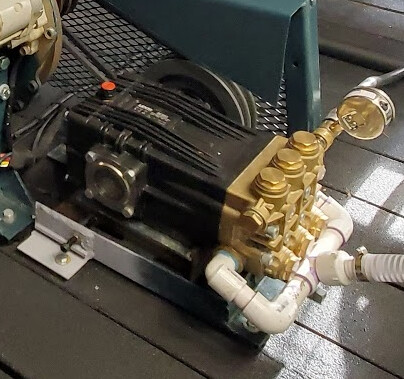

Here’s the setup I use on my Kubota, the factory pulley pack, I grabbed the sheave/pulley from grainger (the right size after measuring the factory Kubota circumference) and a couple of belts. Not too hard. They actually have really helpful engineers that’ll walk you through that part if you need help. I’m not sure about adapting a 1" shaft to these small diesels, I started checking on parts for it and it was very costly. Belts are dirt cheap and easy.

The tensioner I fabbed up with some angle, flat stock, and a center bolt that pulls it away from the engine as you turn it. The bolt on the side just takes the sloppiness out of it since it tends to twist as it tightens that much. You could do the same and face it towards the engine and save some space.

When i checked on a pump from another maker it said i would need 3 or 4 belts and 2 pulleys for the output i need, thats why i want to try and use the gearbox and adaptor that was used on the petter engine it came off, but not sure how to best adapt it to fit.

You could get someone to machine a jack shaft the right size. I can tell you I’m putting more power through 2 belts with no issues though.