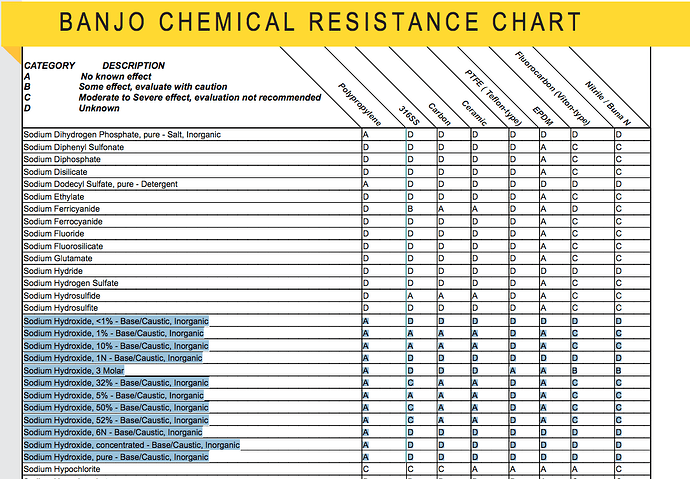

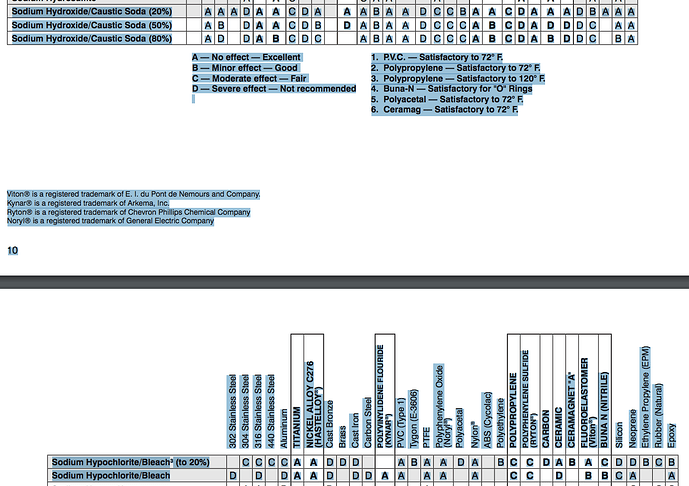

These are screenshots of two chemical resistance charts that gives rating between a given chemical and a given material and how they behave with one another. Not sure if you guys use these already maybe? I can give links to the actual files online if anyone wants. As you can see, sodium hydroxide gets an “A” rating from both PVC and polypro (both aren’t on the Banjo chart like they are on the other), but doesn’t do well with Viton. Some forms or concentrations of sodium hydroxide does okay with EPDM, but I am not sure which kind you would possibly use.

The good news here is that Hastelloy rates an “A” with both SH and sodium hydroxide. That means that the check valve with Hastelloy internals will hold up well with these chemicals. Still probably not as ideal as a diaphragm check valve, but for 1/10th the price or less, that’s very likely the most matched and cost effective way to prevent back flow here.

Thanks for suggesting 3/8" @Infinity. The interesting this is that the GF 523 metering valves (the ones everyone else is using) are only available in 3/8" and 1/2", so you can’t go any larger. The other manufacturer I found that makes a 180 degree meter valve starts at 1/2" and goes up to 2" lol. The OCD in me wouldn’t like mixing the two manufactures together because it’d look bad in my opinion lol. Do you think 1/2" metering valve / check valve / rigid plumbing would be okay for surfactant / soap? This 1/2" part of the valve could still be supplied with 3/8" hose, or 1/2" hose. I guess that would be up to the end user. But if the manifold was designed with 1/2" parts for soap and 1" parts for water and SH lines, do you think that would be manageable? Thank you so much for your input!

@Infinity, could you also talk about how the metering manifold might need to be different in order to accommodate booster pumps or AOD pumps versus just 12V pumps? I was under the impression that they all worked basically the same, with 12V having it’s limitations in pressure and flow, but the other systems being much more costly to purchase and use. It looks like 1" is good up to 16GPM on the suction side of a pump with little to no pressure (image below). That should be plenty. However, if you look at 1/2", it’s only rated up to 7GPM on the suction side, so I can see that a system like this built with all 1/2" components might limit performance of a delivery system that is designed to do more than 7GPM. Is this what you are talking about?

@Greg755, Do you have any ideas on a super simple and economical way that soap lines or even all lines could be flushed with water without restricting and complicating everything with 3 way valves? I’m trying to think outside the box a little bit, but I feel like an additional 3 way valve on each individual line would be the only way to effectively accomplish this. Do you have suggestions?

Also @Greg755, if I was able to give you individual metering valves for water, SH, and 2 or 3 soaps (so 4 or 5 total) AND give you a way to flush EVERYTHING at once with one valve (instead of having individual 3 way valves for each line), that would keep costs down, design simplistic, and flushing quick and easy. What would you think if that was possible?

Thanks for your input so far!