This is awesome. I bookmarked the topic because I fully plan to try this out. You are pitting in some serious work bro!

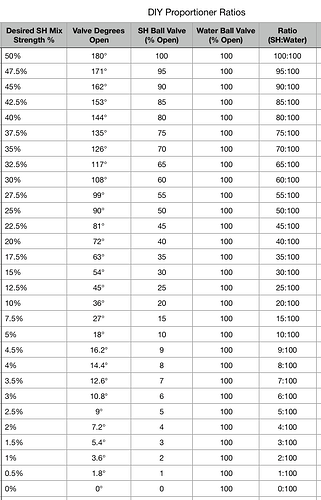

What do you guys this of using this instead of stickers? Assuming the build is naked, so to speak, you’d have to control ratios based on the degree markings on the valve. I created this chart that would show you how much to open the SH valve based on what % strength mix you want, 0-10, then by 5 all the way up to 180. This is updated from the original concept I posted at the beginning. Looking at it, I think it’s probably upside down…Might need to flip it at some point lol. Just now sure how to do that with Numbers and keep formulas correct.

What I’m thinking is that this could be printed and laminated and just used as a reference for employees or if you think you need 10% stronger mix but aren’t sure how much more to open the valve to get that. This way you aren’t using more SH than needed by accident.

Also if you see any mistakes or that math doesn’t look right, let me know so that I can adjust. Thanks.

yes 1/2’ in except for soap. I’ll look later, think 1/4". But has a 3/4" on the out port. From my experience though it chokes down volume with 12v. I think you should look at using 3/4" inlets on all but soap.

Reason why is that when you you have water full on, soap at appropriate setting and then SH set at say even 3 or 4 setting you get X distance. But when you’re rinsing SH side you have it full on and water full on you get about 5-6 foot more. typically with incoming supply you want bigger intake hose than output. Pre proportioner I ran 5/8 or 3/4" intake hoses and got great distance using 300’ of 1/2" hose. So I’d be interested if you could find 5/8 or 3/4 intake valves, at least for the water side.

The valves only go up to 1/2" to my knowledge @Racer. I can inquire for larger sizes. Please give me any other thoughts or suggestions you have so I can put together the best options for the greatest flow.

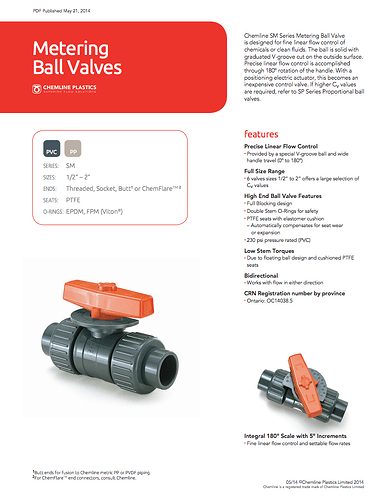

Did some more accidental research. I found a company (Chemline) that makes a nearly identical metering ball valve with 180 degrees of rotation that goes from 1/2" all the way up to 2". You still think 3/4" would be ideal? This is possible now. I’ll have to see if I can get this valve through our supplier at a discounted rate also. Not sure if they stock this, but I noted myself to ask Monday if they can get this brand and what the price would be. List price is identical to the GF 523 metering ball valve, $104. Looks like it could be a good option if you want 3/4" or even 1" if you really wanted it or had a much higher GPM pump. Let me know what you think. Even if I can’t get this at a discount, if there was someone who wanted to put together a super high flow proportioner, this could be their answer.

Also, the compact check valve I previously posted with the Hastelloy chemical resistant internals is available in 3/4" as well. We could go with a full 3/4" DIY proportion if someone wanted. Maybe 3/4" is just overkill. Can it be TOO LARGE? @racer? I see that you suggested maybe just doing the water valve at 3/4", but I don’t think the math would still work for the blend ratios. With water at 3/4" and full open, and SH at 1/2" full open, you wouldn’t have a 50/50 mix. It’d be less than that, and that math is more complicated than I’m sure what to do with lol. I think for the accurate blending to work, water and SH valves need to both be the same size. And then the OCD in my says the soap valve should also be the same size, even if the inlet port is 1/4" threaded to the 3/4" valve inlet side lol.

Note: if you look at this vs the GF in the previous post, this model actually looks more compact. The handle doesn’t stick up nearly as far, at least visually.

This is an exciting thread! Cheers @jzbreeland !

Good question. I dont think 3/4" is oversized in this situation, as people are running 1/2" or 5/8" lines on their reels, and that isn’t a huge difference in size (dont take my word on it, though)… but i’ve often wondered if there is a certain point where the size of the plumbing impacts performance.

Specifically i had the thought when i was running a 1/4" pickup line for my DS injector, and wondered if using a 1’2" or 3/4" draw tube would impact performance somehow.

@PWProducts might have some info as to whether it’s possible to go too big with your incoming plumbing, and where the line might be.

I’m going to tread lightly here in fear of receiving a nasty letter in the mail from an attorney or someone saying I’m selling proportioners or teaching classes on building proportioners.

Pumps do not like restricted flow on the suction/supply side. All of the high and low pressure pumps that we deal with every single day function much better when the hoses are large, non-collapsible, use minimal fittings and are twice the hose inner diameter compared to the inlet port.

The metering or needle ball valves are restricting flow. If using a diaphragm pump, 12 Volt or Air, be careful. Upsize your hoses. It can’t hurt. It can only help you gain distance and flow. Use 3/4” minimum hose ID. Try not to use the union metering valves. They will be the first to leak because it’s tough to get the perfect ‘is it tight enough?’. They are more expensive as well. Use sch 80 pvc hose barbs instead of the poly fittings that are soft and filled with fiberglass that will degrade in sunlight and with SH exposure. If you need sch 80 pvc fittings, we have an enormous selection in every size and configuration you can imagine. Don’t use pvc pipe. Keep it simple and compact and don’t put it in a box. You need access and visibility.

Keep it simple. Don’t restrict the flow. Minimize extra fittings and keep the cash in your pocket and out of the distributors!

Thanks @PWProducts. I see what you are saying about union metering valves, but I haven’t run across any metering valves that aren’t union style. Are you aware of any?

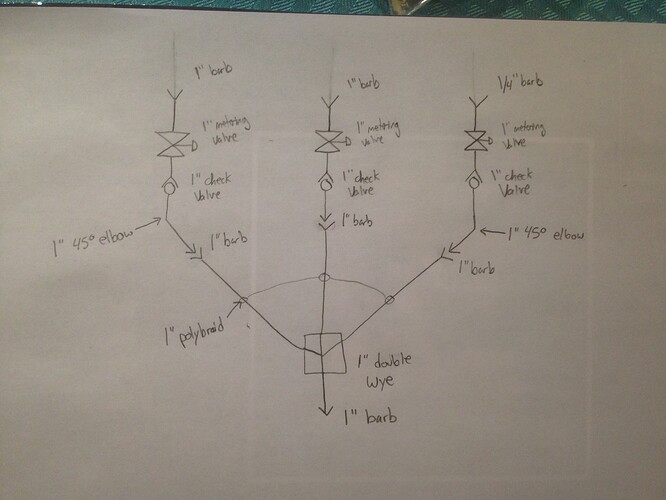

Also, can you and others look through my basic P&ID sketch and give me your thoughts?

Here is the text version: 3 incoming lines. SH. Water. Soap. SH and water are supplied by 1" polybraid hose and go to 1" PVC barb on the inlet of the metering ball valves. Soap is supplied by 1/4" polybraid hose and goes to a 1/4" PVC barb on the inlet of the soap metering ball valve. All three metering ball valves are 1". There is a 1" Hastelloy check valve after each metering valve. SH and soap have a 45 degree elbow to a 1" barb, and water has a 1" barb with no elbow right after the check valves. From these 1" barbs there is 1" polybraid connecting all 3 lines to 1" barbs on a black PVC double wye with a 1" barb on the outlet. All fittings are PVC, not polypro.

If I’m looking at this right, this is most efficient way to direct 3 liquids into 1 line with the least restriction. There are no 90 degree turns, and having polybraid hose in the middle of the unit would allow operators to visually check that their mixes are pulling at the actual device and not just incoming lines going into a covered box.

One possible alternative to this would be to use 1/2" or 3/8" fittings, metering valve, check valve, and hose for the soap line since that is such a small portion of the mix. It seems to me like 1" might be too large and could cause problems this way? Can you give me some feedback? But in my opinion at this point, this layout is the simplest and least restrictive, even if the soap line should be downsized.

In case anyone didn’t know, this is a black PVC double wye. Though it doesn’t have all the same inlet sizes, I’m sure I could find one with some searching.

Rotameters for flow rate?

Ohhh… adjustable flow. visual indication.

Yes.

And cheaper than what you trying to do…and works th e same

Outdoor rated for this type of heavy use? Also up to 10gpm? I’ve only seen these used for fine tuning very low flow rates.

U use this with a double barb chemical injector.

I got a 8gpm and works fine.

Are they glass? I’m not confident that’s the robust solution I’m looking for, though I really appreciate the suggestion!

People have been using valves to control flow or to mix things for ever. Just stop calling it a “proportioner”…

Acrylic

Perfectly stated Greg755! Understood!! Mixing valve setup!! I’m happy to help!

@PWProducts waft do you think of my sketch? Suggestions?

What are your thoughts on using smaller diameter valve and supply line for the soap?

Beautiful work!!! I agree with your set-up. I am recommending against the clear braid poly. It is too soft in the heat. Have you found the wye in anything other than socket? That’s crazy!! I was just looking at that same fitting today in 3” for a Customer. I like the tremendous amount of thought you put into the build. It shows. Yes, they make the metering valves in threaded non-union types. We sold the valves years ago. I saw them online a couple months ago but updated my phone and lost hundreds of saved pages. Ugh. Message me and we can go over it if you are interested. I like it. Not too much to change. I’m worried that the 1/4” hose might be too small. Does anyone else have any feedback on that particular hose ID?

What filters are you using? Do not use stainless steel on the SH.