What was your percobonate mix ratio?

Two cups per gallon, mix with hot water and apply applied with a pump up sprayer. Pre-wet the wood and apply, dwell as needed, do it in sections, scrub with the grain. I like the black Quikie brushes, they are about 8 dollars with handle. I had almost no furring.

Thanks. I’ve been using dsr-49. 16.50 for 4lbs. Do you use raw chemicals or a product?

Also, every time I mix this stuff in the morning before I leave it foams over out of the bucket and makes a mess. I read that this chemical should be used within 6rs. Has this been you experience?

This one?

I’ve never used DSR-49. I use powdered percarbonate. I use DSR-50 Potassium Hydroxide as a degreaser.

I know this topic has been discussed a lot, and I am not asking for an exact number. The client would like this deck stripped and resealed. To include hydroxide stripping of the deck, resetting of all nails that are beginning to back out of the base materials, and lightly smooth up hand rails and high touch areas with a sander. The upper deck portion measures 10’ x 34’ and the lower section underneath measures 10’ x 16’. Rails, stairs and ladder work on the upper and just a flat area on lower. These areas were never painted and only sealed with a stain or Thompson’s product from what the homeowner could remember. He also mentioned spending some time cleaning the under side as well.

Based on my research, I’ve come up with a price of around $2600.00 to strip and refinish this area. I know many do not like to get specific on pricing, and that is okay with me. I just don’t want to have the client fall over when he gets the estimate, and I certainly don’t want to short myself and be way under water on the project.

Thanks for any help.

I think you’re close but maybe a little low considering the sanding, driving nails, ect. Figure about $3-$4 per sq/ft for stripping and $5 per linear foot for railing stripping. As far as the sanding, nails, cleaning underneath, etc just try and ballpark how many hours it will take you and multiply by your hourly rate. I’m not sure what you charge for regular deck cleaning but let’s say it’s $.50 a sq/ft. I would up that price a little for underneath the deck since it sucks…lol

That top deck doesn’t even look like it needs stripped. Maybe it looks different once you see the deck boards.

Thanks guys. I did see that form and used it as a guideline for myself. I just like to hear input from others. There are often points to consider that are easily forgotten during the estimating process. Thank you for your help.

Sounds about right to me too. You’re probably going to find that 90% of the people with decks don’t want to spend the money to take care of them properly. You’re not too high and he’s probably going to have the big one, lol.

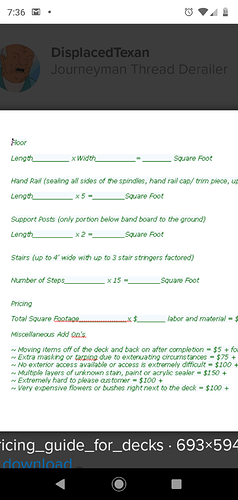

I converted Ricks picture to a word document so it would print cleaner. Deck Pricing Sheet

Good evening,

I wanted to share a few pictures of the finished deck project. The last time this deck had a finish applied was in 1995. Since then, It has been left pretty much untouched. Thank you to those who were willing to share information and to answer questions I had when I started this project. The process I used was as follows.

F18 Hydroxide from Pressure Tek mixed at 8-10 ounces per gallon to strip base finish. I also added 1/2 cup of 12.5% SH to my mixes. I felt the added SH really improved the overall cleaning power. I applied the chemical with a pump sprayer to 3-4 boards at a time as to not get too far ahead with being able to wash appropriately. After 15-20 minute dwell time, I utilized a 40 degree tip 4-6 inches from the surface…just so the fan covered each board… I started at one end and maintained tip distance as I walked the deck doing my best not to stop or restart at anytime. Deck spindles I hit at a 45 to attack both sides in one pass. Overall, the cleaning process worked well. There were some areas where it was harder to clean than others, but I believe what I was seeing was the beginning of the wood actually starting to rot. I say that only because I literally couldn’t sand it out, and upon further inspection, it appeared to be very soft and beginning to decay. After the deck was stripped, I used the X-Jet to apply Oxalic acid to neutralize the Hydroxide.

After cleaning, we reset all the nails that were beginning to back out, and sanded the high touch areas (handrails). For stain, we chose Armstrong Clark Stain in Semi-Transparent Cedar. Overall, I was pleased with the stain.

The customer was very pleased with the final results. It was a great learning experience for me, and I just wanted to share my exact process. I learned a lot from contributors here, and I enjoy reading how people approach their projects. Hope some of this is useful.

Please provide insight or thoughts. I like to hear opinions and different methods.

Thanks again!!

hi, does the stain and seal combo price include the stain?

It looks nice but it’ll never last very long. When staining a deck that hasn’t been taken care of, I rarely suggest semi transparent materials. I would’ve chosen a semi solid or even solid color stain because they give much longer life than the transparent stains.

I’ve got 22 years as a professional painter and have learned this through the years. While the semi transparent stains look very good, they typically don’t have the longevity.

Part of that is simply what the customer is looking for.

A semi allows you to still see the wood grain and it has a more natural look. A lot of customers like that.

Hello, can you clarify, you said, “F18 Hydroxide from Pressure Tek mixed at 8-10 ounces per gallon to strip base finish. I also added 1/2 cup of 12.5% SH to my mixes.”

You mixed hydroxide and SH together in same mixture, together at same time, applied all at once together? What are active ingredients in the f18? anyone know? sodium percarbonate? sodium bicarbonate? soda ash?

If they were mixed together, what was cleaning effect? did you see the sh brightening effect at all? Was there a seeming toxic fume more than normal sh? thanks, just real curious. btw, I think you did awesome job man looks great.

F-18 is just sodium hydroxide. They just call it F-18 to label it as their own. I usually just buy it from ebay.

Here is a link to my most recent wood restoration project. With this project, I did not add SH to the mix at all. It was as described in my post. There was a significant amount of organic growth, and this mix with only the hydroxide (f18) worked great. From what I have learned, you can use SH, percarbonate, or hydroxide as wood cleaners to kill organics. If you are using F18 as a cleaner, you would want to dilute it out further than if you were using as a stripper. Basically just enough to accomplish what you are trying to do. A lot depends on the condition of the wood you are cleaning. For example, had the deck been 4 year old treated lumber with no finish, I would have opted for percarbonate, but this deck had an existing finish that needed to be removed, which is why I elected to use the Hydroxide. With hydroxide and SH, there is more risk with furring the wood. I would consider percarbonate the least aggressive and most wood friendly… it just takes a little longer. As far as the chemicals are concerned, F8, F10, & F18 are all chemicals from pressuretek.com. F8 is your oxalic acid, F10 is your sodium percarbonate, and F18 is the Sodium Hydroxide. There are also tons of finishes out there to consider when approaching your processes.

The wood will certainly look “brighter” after you use a mild pressure rinse, but the true brightening comes at the end when you apply your oxalic acid to neutralize. You can literally watch it brighten up.

Thanks for the compliment on the project. I am still learning too. This forum will teach you everything you need to know if you read enough!

I bought a bag of oxalic acid powder form. It did not dissolve in hot tap water, I had to put it in very hot water from pot, first time messing with the stuff, I think buying it in powder was a mistake?

I like sodium percarbonate best , long dwell, power wash for real.

I need to try the sodium hydroxide. That is powder I think?

I could buy F18, put that on, then put on F8. I would like to try that process.

I like to make my own. Just wondering about that. I have the sodium percarbonate worked out to make lots of it ok. I had great luck with it removing thomson water seal , oil based tinted, and power washing. It had only been on there a year, and water beaded right up on it, but when I put the peroxide on it, in seconds the water was soaking in. On wood with really lots thompsons, the vertical thin cedar wood, I had to do it 2x, but it came out all completely bare cedar. I used about a 50 percent stronger than normal too to try to get the thompsons off.

Anyways, thanks, that was a great explanation of stuff, and generous with knowledge