It worked great yesterday, all day. Got to the job today, worked great for 5 minutes then all at once it was basically garden hose pressure. Thought it might be the unloader so I took it home to do some troubleshooting. Nothing coming out of the bypass when off trigger. Nothing coming out of the hose with ball valve wide open. Deleted the unloader & tried the ball valve straight off the pump & it’s pretty much garden hose pressure. 6.8 gpm Allison pump with about 300 hours on it. Check valve issue maybe??

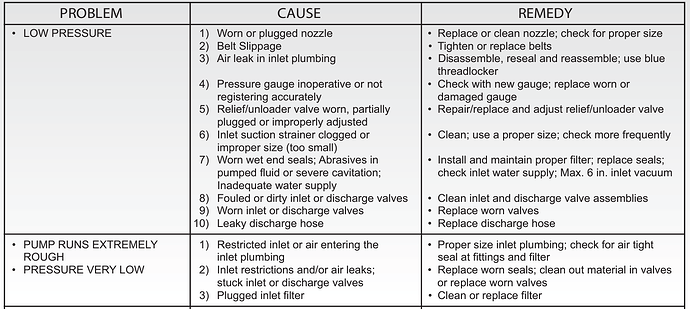

This is what my udor pump says for low pressure troubleshooting… so if you are sure nothing is leaking or clogged and it’s not an unloader issue… I would say it’s a pretty good bet that the valves need cleaning or replaced. If that all looks good then I would move to the plungers.

How is the oil level?

Went thru this earlier this week… we were about to pull the PW and slap the spare on when I thought to tell them to check the check valve. It was pretty bad, but in the end there was a tiny round piece off our float valve wedged into the elbow coming out of the buffer tote…

There’s a few other possibilities for you

You can loose pressure and pulsate sometimes with bad check valve or valves….

Check valve is pretty likely if it’s a sudden occurrence. If it was a slow decline in performance I’d say probably a cracked plunger or wiped out packings. Usually the furthest check valve from the pump inlet is the first to go so I always check that one first

Did you check your suction filter? If it’s full it won’t allow the pump to pull much water

I appreciate the advice gentlemen! Everything is clear. I took the check valves out today & cleaned everything up. They used 2 gallons of threadlocker blue on each bolt when they put it together. Got everything reassembled. Force fed the pump until water came out of the whip line. It won’t spray a single drop. My 4gpm GP direct drive gave me at least 1,000 hours without a hitch. It’s about to go back on there to save the day once again.

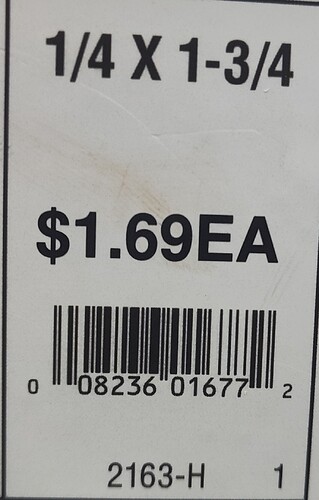

Turns out the pump actually works a lot better when it’s actually being spun by the engine. 1/4 inch by 1-3/4 crankshaft key for the win.

What happened to the old one? Just worn down or fell out?

It turned into a spoonful of rust and sheered. The one I got today is stainless and very shiny. I made some other upgrades while I was at it so it was a good day. Just glad it was a $2 fix

Rust with only 300 hours? Sheesh. That’s crazy. Do you keep it outside?

The key came from a Predator engine, so that should have been a red flag from the get go haha. I’ll take the blame but as much time as I have invested around small engines over the years, I never knew stainless keys were a thing until I had one in my hand today at the hardware store. I didn’t know what I didn’t know but now we all know. It’s a constant learning process. I put quick connects on my whip lines and unloader while I was at it, so it’s an improvement altogether for next time something craps out; which always happens on the job.

Got a pic of the bad part causing the issue?

This is what was left of it. The other half was dust.

More importantly, this one from Ace Hardware is the one to get…

@qons My rig spends a fair amount of time outside but if it’s going to rain me out for any significant amount of time I put it in the garage. I would rather work in light rain & take a pretty day off.

1/4in x 1/4in barstock or stainless. i put a full length fitted piece. some manuf just put a little 1/2 piece.

Our Kohlers were throwing them like crazy a couple years ago… I bought the 1/4" bar and we cut them to fit the channel length. That moved the failure onto some other lousy component on those things ![]()

One of these days, somebody is gonna take a big sackful of tomaterz to the wrecking yard and stroll outta there with a 20r or something for a belt drive rig.

After breaking another key, I see what the issue was… The 1-3/4 key is perfect for the GX630 but the hollow shaft on the gear box has a 3 inch long groove so the key walks until it breaks at the 1/2 inch mark. Longer key did the trick so far but now I’ve got a massive oil leak coming out of this area in the photo. 1 ounce every few minutes. The vendor has already sold me 2 different O rings (one I didn’t need & one that doesn’t appear to fit anything I own) & they are now trying to sell me another one. Anybody have any experience with an oil leak on the engine side of the gear box?

…and the latest recommended part.

Hopefully this isn’t what it is, but I’ve heard of longer shafts and keyways poking holes through the gearbox. That’s the only time I’ve ever seen someone talk about oil leaking from that area if the O-rings are good. Are you using spacers in between the engine and the gearbox?