I am a weekend warrior and have a question regarding my pressure washer. I have a AR 4GPM 3200psi machine. It is my understanding that having the machine running for an extended amount of time off of the trigger can cause issues with the pump. That is due to the unloader opening and the water bypassing and getting recirculated through the pump again. It can get very hot and cause problems. Is that the theory on what happens? If so here is my question. I am trying to increase the draw rate while down streaming. I can significantly increase the rate if I use the unloader and reduce the pressure to 500psi. My question is if I do that isn’t it doing the same thing as being off the trigger while running but just to a lesser extent? Of is the smaller amount of water that it is allowing through enough to keep the recirculating water temp low enough.

Thanks…

Just change the tip to get your pressure down to 500psi. Dont change the unloader just change the tip. Larger orifice=lower pressure.

Do you think think that I would achieve the same increase in chemical draw? I was thinking about that but I was afraid that with that much volume I would not get the draw rate i was looking for. I was doing it to increase draw rate more than to decrease pressure. With set at 3200 PSI the black tip had a rate of 1:15. If I turned it down to 400psi with unloader it increased the draw rate to 1:3.5

how is your distance with that low of a psi from the pump?

It is not great but it is enough for me to soak the roof. I am trying to get a draw rate high enough to clean a roof.

You’ll need a dedicated roof pump for that, 3-4% or more strength. Downstreaming won’t cut it.

I figured that the most I could get is around 2.5% starting with 12% so I knew it would be close. But my original question is would it be bad for the pump. I could use it for fence, stucco, and presoaking driveway. More curious about pump than anything else. Thoughts on that?

its still going to do the same thing, likely your just buying some time with the smaller amount of friction the water has recirculating itself. How much time, dont know.

thanks… I would rather do something else than take a chance on hurting pump.

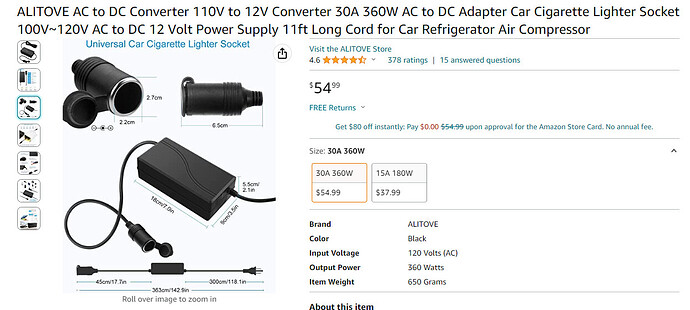

I am going to probably just get a 12V pmp and do it by batch mixing. One more question if you don’t mind. If I do a 12V system I would be interested in trying to power it without having to have a separate battery. Do you think if i get something like below that is 30A and cut the lighter end off and hardwire it would work?

Other option would be a DC converter to use a battery from 18V power tool.

myself, i wouldn’t risk something going wrong and burning up the auto mobile.

Don’t try to work around things, make a dedicated 12v system with separate deep cycle battery.

Super small buffer tank might be a quick solution

Stop taking shortcuts and just do it right.

The last thing you want to do is use a pump powered directly by your vehicle’s battery. If you create a short somewhere you’ll drain the battery too low while using the pump and you won’t be able to start your vehicle and that’ll be a bad day.

I started with just a $35 lawnmower battery from a box store and then ended up finding a good used automotive battery for a $50 on FB marketplace. Better choice then $50 on an inverter off Amazon.

The auxiliary circuit that runs the lighter outlet is usually rated for 10 amps max. Definitely won’t work for a softwash pump.

FWIW, I did that once to run a wfp pump in a previous vehicle. I did end up with a dead battery at a customer’s home. Kind of embarrassing and inconvenient. Definitely use a dedicated battery for your rig.

Edit: regarding your original question about the unloader, if you’re recirculating the majority of the flow with the unloader, that will increase pump temps somewhat, but probably not significantly. They make “weep guns” for carwashes that essentially do the same thing: allow a small amount of fresh water to flow through the pump to keep it from overheating.

That said, I don’t think it’ll work for what you’re attempting to accomplish. There’s a good chance your injector just won’t pull with that little amount of pressure. You need a certain amount of pressure differential for the Venturi vacuum to work. Accounting for backpressure from your hoses and gun, you probably won’t have the needed pressure drop at the injector.

Also, it’s unlikely to put out a hot enough mix for most roofs.

Thanks for everyone’s reply. After seeing some of the replies I think that the picture may not have been showing what I really wanted to do. I am going to only be using this 2 or 3 times a year on my own house. It will not be used daily or weekly. The cost of a 110V pump was 3x the price of this pump. I am not going to be using it with the cigarette lighter or on my vehicle’s battery. My plan was to plug it into 110V at my house and cut off the cigarette lighter and hardware a 2 pin adapter to match the adapter on the pump. It was more about not having to keep up a battery than anything else. I have a little generator that has a 12v outlet that i could probably use. Not necessarily trying to take short cuts but more curious about other options that might work in my case for the relatively little use compared to you pros. I do appreciate your comments and replies and enjoy reading forums such as this one. thanks…

They make 120v pumps similar to the 12v ones. If you’re just going to be using this at your house, that’s what I’d recommend. Just make sure your outlet and extension cord is protected from any overspray ![]()

Back to your original question, set your unloader properly & throw away the knob. You can throttle down your engine & achieve the same result of decreasing flow to get a hotter mix. If I were in your shoes, I’d get a fancy injector from @dperez & skip the 12v. I personally think 12v rigs are overrated & I have one sitting in the garage. Check out the xjet while you’re at it & don’t underestimate the power of dwell time.

Can send me a link to your product?