I own and operate a company in the Pacific Northwest that offers moss removal, gutter cleaning, window cleaning, exterior cleaning, and pressure washing. I never offer to pressure wash roofs, but I do dilute and disperse liquid moss treatment on roofs using the pressure washer and the soap nozzle (it sprays further than a Juice Box and it beats walking a roof with a garden hose and siphoning nozzle going to a 5gallon backpack of treatment).

I will try to keep this short as I do have a couple simple questions, but I would like to layout the scenario in case any members of the forum have some insights, advice, or suggestions about other aspects of the situation and my decision making process. I highlighted my questions in bold if anyone reading wants to skip the rest.

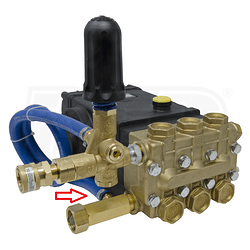

After a year of putting DeWalt’s 4000 PSI 3.5GPM model through moderate use, the power boost began failing causing the detergent injector to lose suction. I have decided to purchase a more reliable product and after talking to a few dealers in town have settled on a BE gas direct drive 4000 PSI 4 GPM, Honda GX 390, General Pump EZ4040G shown here: https://www.bepowerequipment.com/pw-13hp-gas-gx390-4000psi-ez-7d5d8691-d91e-4b89-94ac-ef779f87add0

One of the dealers I spoke with recommends that I let them reroute the thermal bypass so it drains straight out the bypass hose. The reason being that by the time the thermal relief valve were to open, the pump is already hot enough to be getting excessive wear and damage. What prompted the dealer to suggest this is the fact that the sort of work I do does sometimes involve several minutes going by without pulling the trigger on the wand. They said they do this modification for all their rental equipment and for several other contractors they sell to. Another dealer told me this was nonsense and the thermal relief valve is sufficient to keep the pump from overheating.

My first question whether or not it is worth it to reroute the external thermal bypass hose so it just drains out an open end for the sake of extending the life of the pump?

Now I found the exact pressure washer on sale from an online retailer. The dealer charges $100 more for the same model, they tell me it will be several weeks before they can get one in stock, and they do not offer to do the thermal bypass modification on pumps they did not sell directly.

My second question is that if it is worth it to reroute the external thermal bypass can anyone link me to a step-by-step walkthrough of how to do this?

My ultimate goal is to have the pressure washer on a wheeled cart, but it will remain mostly stationary in the back of my truck, positioned so that the rip cord and exhaust both go out through one of the side openings on the topper. If I rerouted the thermal bypass hose I would extend the house out the tailgate and let it drain onto the street.

Hope some of you can help answer these questions. Thanks for reading!