Thank you @Racer, I appreciate your help. Sometimes you start to search and search for a simple question and get frustrated when you can’t find a straight answer. None of my runs will exceed 6-8 feet from tank to proportioner and less to hose.

Did check - my intake lines to proportioner are 1/2", both about 6-7’ long - from PP to pump have 3/4" spiroflex - only reason I have the 3/4 is I needed the spiroflex because it’s going thru a metal cabinet and 3/4" was smallest diameter I can get… from pump to reel, it is 1/2" and is about 10 ft long.

Make it a YouTube video. I doubt anyone is going to put they email address in to watch a video. Did you say you were running two pressure lines from the unloader?

Reposted with you tube video link:

Please help/give advice on a pulsing unloader:

I have everything plumbed up and began all the initial testing in my rig but there is one issue that I am not sure if it is normal or not. I have a predator670/udor 30/24gr 8gpm build which is fed from a 1" suction hose. The pump runs into a 30" 3/8" whip line to a zk1 unloader, screwed into a 3/8" unloader block - 1/2x3/8 reducer - 3/8" hose barb - 1/2" bypass hose to tank - 1/2" fitting into tank. Outlet runs 3/8" whip lines (x2) to hose reels.

I set the unloader as per guidelines and I get 2450 psi at the gun with a 2510 tip (purposefully kept 50 psi shy of 2500). When pulling the trigger is runs like a charm and pulls 5 gallons in 37.5" which is right on 8 gpm. My draw rate using a GP High Draw 2.1 = 1:12.8 which puts me at just under 1% using 12.5. I didn’t think that I was going to get anywhere near that high so I am pleased with that.

The problem is when I let off the trigger, the machine give 2-6 “pulses” (quick on/off) of pressure that spike the gun up to 3000 for a split second. The surge that goes through is enough to rock my 2 hose reels that are stacked off the trailer deck (haven’t made the final resting home yet). After it goes through its pulse cycle, it settles in like a kitten purring. I am not sure if this is a normal settling of pressure or if this is something abnormal. Sure looks and feels abnormal but I haven’t used a flow sensitive unloader before.

I went with the 1/2" to 3/8" bypass reduction based on the recommendation from Russ at Southside equipment. It’s run into a 1/2" hose b/c I had extra didn’t feel like running back to the store again. The 1/2" tank fitting was purposeful.

Here is a video if you care to look. Any advice is appreciated.

Thanks for the youtube advice. First time doing it. I reposted.

No, one 3/8" pressure line coming out of the unloader. There are two connected hose whips to the reel so that I can put my chemical injector in and out in between the two lines.

The bypass line going to the tank is 1/2" poly hose but it is coming out of a 3/8" hose barb. I don’t know why that was recommended since the manufacturer made it a 1/2" bypass for a reason. I would think that I would want to keep it at a 1/2" hose barb.

Well, I just changed out the 3/8" hose barb for a 1/2" hose barb on the bypass at the unloader and I would say that it overall had no effect. Maybe not as big of a surge.

If this is normal, I’d just like to have someone confirm it before putting it into service. Thanks.

Just wanted to post a finding for anyone using a zk1. I have continued to play with the barb/hose size in trying to get rid of the pulsing/surging happening when the unloader went into bypass.

After changing to a 1/2" barb to 1/2" poly line to a 1/2" barb at the tank with perhaps a little improvement but still with definite surges and times that it just didn’t run right, I change everything to 3/8". barb, hose and tank barb. This caused a definite worsening of the symptoms. Continuous surging on/off for 20 seconds and pulsation at the gun when pulling the trigger. I quickly stopped.

With the theory that I was just getting too much back pressure, today I moved everything up in size: The bypass is a male 1/2" mpt. I place a 1/2" coupler, 1/2"mpt 5/8" barb, 5/8" hose line (about 6-7 feet) to 3/4" barb on the tank. This completely eliminated the surging and resolved the problem. I only ran a short period due to time constraints, but I am confident that this was the issue

Hope this helps someone, I can’t be the only one to ever have had this issue given the mechanical nature of it.

How is that Herculiner holding up to SH?

I was considering EPDM Rubber Roofing Membrane or Herculiner

I made the mistake of putting Herculiner on my trailer few years ago. Worst thing I’ve ever done. Will never use again on anything.

I heard other recommendation Raptor bed liner, what is your recommendation?

Had a buddy use that on his hunting rig. Lasted maybe a month.

We get the beds of our trucks done by Line-X before we drop the skids in them. Seems to hold up just fine.

Line-X or Bullet Liner would be my go-to. Raptor Liner is supposedly very good for the DIY guy.

It is holding up for me and I am very pleased with it. I can only give you my experience with it. I prepped my entire surface very carefully and rough sanded the entire area I was going to apply it to. I can’t remember all the steps off my head but followed instructions to a “T”. Watch your humidity and dry/cure times for your reapplication coat. I think it is great. Has a very rough textured surface. There are little “rubber chips” in there that you should stir up regularly so it doesn’t sink down. I used a power drill w a paint stirring attachment. You can (probably should) cut it down w XYLENE Only. Cover if not using as I think it evaporates quickly and wear a respirator. I know the foam rollers it came with disintegrate apparently. I got a textured Paint roller (unique goop loop pattern) which was on a youtube video. But I think that I just brushed and dabbed the whole thing on b/c I still have a roller here?? I only do this part time and the trailer is enclosed so it is not being weather beaten all year. I try not so spill chem on the floor or a lot of H20 but I regularly just rinse down the inside b/c it is rubberized. It is working for me for 1 season. I would recommend. Haven’t openned up the trailer yet, but soon. I’ll let you know if there was any issue w freezing but I can’t imagine there would be. Blessings!

What brand kit did you buy? Rust-Oleum EpoxyShield 240 oz. Gray High-Gloss 2.5-Car Garage Floor Kit 365187 - The Home Depot

???

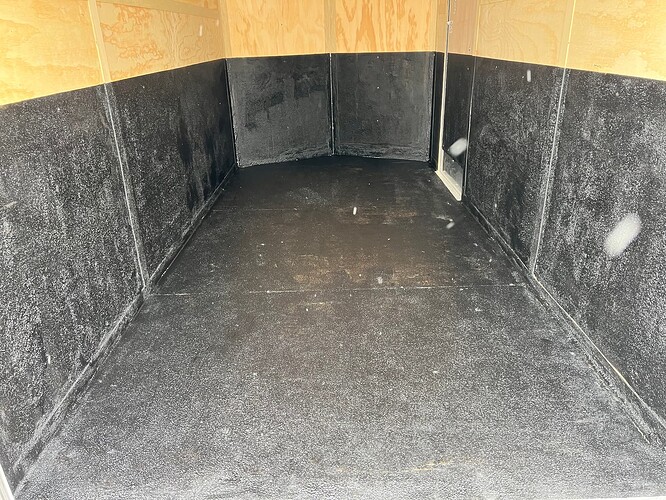

No, none of those. I used Herculiner, gray. I did not like the black. I am almost positive that I used 1.75 gallons four of what you see in the picture. That included the floor and approximately 18 to 24 inches up the side walls as well as the entire ramp door

My bad man I missed it in the first post lol, its looks nice and I wanted to copy you! Total bummer no body sells the gray around me, so I went out to Menards today and bought two kits of the black ![]()

How bout a picture of the finished product?? Assume it’s done by now.

I applied 1 coat to the walls and 2 coats on the floor. This picture is after the first coat, I applied a generous amount on the floor for the second coat. 2 gallons total for this, 6x12 trailer, I am happy with it but learned my lesson with the rollers that came in the kit lol they don’t last! It started shredding apart and leaving junks on my floor lol

I’ll have to get a new picture tomorrow and show you what I’m up too! I put a workbench in the front and reel rack on the side door ![]() getting ready for my first full season

getting ready for my first full season ![]()

Edit:

Here is how my trailer is looking so far ![]()

Did you make that steel table yourself?