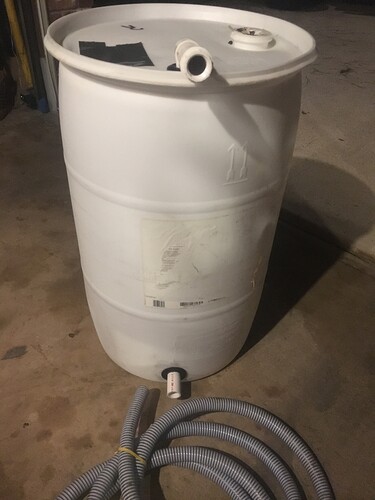

This gets mentioned occasionaly… here is how i set one up a while back (I use a 275 tote now).

Obviously this isnt as pretty as a tank you can buy from TSC, but it gets the job done, and is a lot cheaper, if money is tight.

A buffer tank and the plumbing, can sometimes seem intimidating to a new person, but remember we aren’t trying to keep harsh fumes enclosed, or protect against corrosion, or keep chemicals from getting weaker from UV rays or anything… we’re just holding plain old water, and draining it… a milk jug can be a buffer tank if you poke a hole in the bottom.

Get a drum off craigslist for $25 or less… or free if you know someone who has one. Get a white one, if possible, so you can see the water level.

Cut a hole big enough to get your arm in on top. When everything is hooked up, put duct tape over it to keep trash out.

Need to install a Hudson Float Valve on top. Get those at TSC or online. You can buy a bulkhead fitting from an ag store, or online… generally around $10 for a 1"… or you can go to Home Depot and get electrical conduit fittings like these for about $1.

Put an o-ring on it, if you want, but it isn’t really necessary except for at the bottom.

Only drawback to doing a bulkhead with these fittings, is that you will need to glue in PVC pipe to make the threaded connections for the hudson float valve to screw into. I had all that laying around, so i did it this way. You might want to just spend the $10 for a bulkhead fitting, as it has the threads already on it.

To make the hole for the 1" fitting, i used a 1 1/4" wood bit.

Screw the two pieces together through the hole.

Put a 3/4" barb on top, and the Hudson Float Valve on bottom. That’s all there is to it for that connection.

At the bottom drill another hole and put another bulkhead (or electrical fitting) just like you did up top. Here you will probably want to use an o-ring. I also put some silicone caulk around it, just to be sure. I had zero leakage.

That’s it, you now have a buffer tank.

You might want to put a T on it with a ball valve, so you can drain it if you want. Just have the straight portion of the T going to your PW, and the 90 for the drain.

Also, you will want to run your bypass hose from your pressure washer to the top of the buffer tank. Just use 3/8" air hose (or whatever size yours is) to the top, and use a 1/2" bulkhead, and plumb a 3/8" barb into it… or sometimes you can just get two 3/8" threaded fittings and sandwich them together on the hole.

A filter before and after the buffer tank is recommended.

The lids on most 55 gallon drums have knockouts and are threaded… you can use them for connections, but i just used these fittings. Doesn’t really matter how you do it, just as long as the HFV is connected at the top.

Any other little tips people have, or input on how i did the drum, is welcome.