Pass on this job like others (with more experience than me) have said. This is too much for a 12v as well. 3 stories with any sort of breeze would be a huge headache. And it would take a super long time with 12v because of the gpm limitations. Also, 4% - 6% SH is strong, it would be good to have a lot of experience with those dilutions before using them on historic buildings. Good on you for asking the questions though.

the building was actually remodeled not too long ago inside and out due to flooding and not much remains from the original. do you till think 12 volts is the best way even with its limitations?

thank you for your feedback.

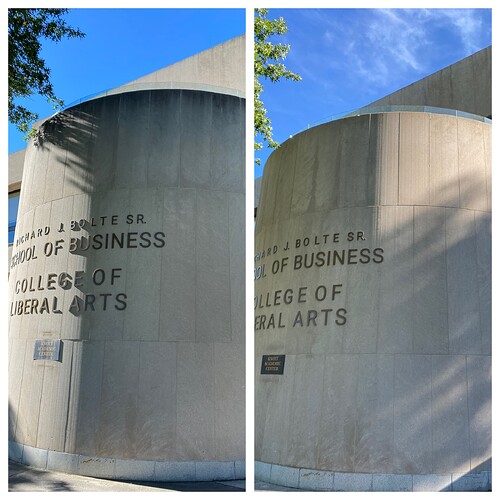

Based on the door height on the second building I’ve estimated 44’ so figure 15’ up or so on a ladder, YRMV. Not everything has to have a big honkin gas SW rig hitting 60’ +

Those damn spindles…

A building of this size could easily be handled with a 5-7 GPM 12V system. A lift would be needed, and if you have never operated a boom lift, I highly recommend reaching out to a local rental company for training. I know the Sunbelt by me offers man-lift training, you also need to understand and use fall protection when operating a boom lift. That way you don’t look like a clown trying to figure out why you can’t operate from the basket, or even fire the the thing up.

As you said 4-6% is pretty strong, but usually required for porous, vertical surfaces. It is very important to understand what type of material the exterior consists of so you know 1. How your chems will interact with them… 2. What the maximum amount of pressure you can use is without damaging the surface is.

This was all done with an Everflow 5.5GPM, a 5.5 GPM Washer, a lot of SH, and a 60ft JLG in about 2.5 days for two guys. One guy in the lift and one on the ground.

You’d be amazed at what you can accomplish with that basic setup, as well as the amount of confidence you gain from successfully completing a job like this. Keep in mind it takes a lot of prep, planning, and definitely an extra set of hands

6% is way too much. 4%. You would probably only need on like 10 or 20% of that building but we should really talk about potential problems . That limestone doesn’t always play nice with SH. You might end up significantly discoloring it beyond repair, not to mention unless you’re providing serious protection to the grass it’s all gonna be dead pretty close to where the building is before you’re done washing one side if you’re using that strong of a mix. If you spent another 20 or 30 hours reading on the forums and then came back and asked the questions you would be better off. People here are willing to help but they’re not gonna spoon feed you information that is readily available using the search bar.

I can’t believe I’m about to say this, but where is @Innocentbystander bystander at?![]()

I’ve been working in the heat and my brain is fried when I get home

I feel it. Take care of yourself man

I should also add that no lift, regardless of tire width isn’t going to not destroy that perfect grass. It’s got to be watered regularly and those things weigh at least 12,000 pounds. You would need to rent heavy equipment pads to drive it on. With the amount of money you will spend on renting a lift like that for a week and pads plus all the labor to go get the pads and move them around all over the place might as well just buy an AR 45 for that job or just oversize it and get an AR 60 to do it all from the ground. But I would highly recommend learning a lot more before attempting something like that. And remember test areas are key. Also, you need to let everything dry before you make a final analysis. Another thing about test areas is you need to do test areas on all four sides of the building. Might not matter so much on limestone, but on a painted surface, you might run into some oxidation which will get you in the trouble if you don’t identify it, communicate the issue with the client upfront and set expectations.