Thanks for the clarification. I guess I shouldn’t rant when I don’t know what I’m talking about!

Everything you said makes completely sense though. I would’ve wanted to kick them in the nads to if I found out they really were bsp threads. At least I don’t have to get all mad now…lol. I guess that’s why the vendor or manufacturer told Jake that it was too expensive to worry about switching to npt. They almost have to be compatible for a company to just roll with it.

Yup check out the specs on the General TS2021 here

- Inlet Port Thread: 1/2-14 BSPP-F

- Discharge Port Thread: 3/8-19 BSPP-F

I got a 1/2" block, even trade for that barely used k7 ;>)

I’m sorry man, but as a plumber I’ve gotta disagree with this. Yes, you can deform the brass to make it screw together, but BSPT and NPT should not be used together. I’m still super unhappy that the K7 came with British straight pipe threads, especially because it was sold as being NPT. Below is an excerpt from a well-renowned pipe resource. Google NPT/BSP compatibility, you won’t find a single place recommending it. That being said, my adapters are on the way.

WARNING: Never, never try to mate a BSP fitting with an NPT or NPS fitting if the pressure holding capability is at all critical.

NPT/NPS and BSP threads are not compatible due to the differences in their thread forms, and not just the fact that most diametrical sizes have a different pitch. NPT/NPS threads have a 60° included angle and have flattened peaks and valleys (this is a Sellers thread form); BSP threads have a 55° included angle and have rounded peaks and valleys (this is a Whitworth thread form).

Also, every other part of my entire system is NPT (except for the garden hose fittings), including the Udor pump. Can’t speak for General Pump, it looks like most of their stuff is BSP

Guys, we fought --and won-- a war against the Brits. Let’s not use their wonky pipe threads on our Japanese and Italian pressure washers, please. Remember the shot heard round the world? Never forget.

Do as you do

We fought and won a war against the Japanese too so you better trash that Honda. I guess we fought Italy too though so looks like you’re off the hook because all pumps come from there…lol

Hey @Jake_Lambert . Where’d you order your fittings from? I remember you posted that picture or link the other day but can’t seem to remember which thread it was in. I’m not getting over 1 turn with a wrench so kind of makes me nervous to use.

I’m keeping the Honda lol

Just throw some blue loctite on it.

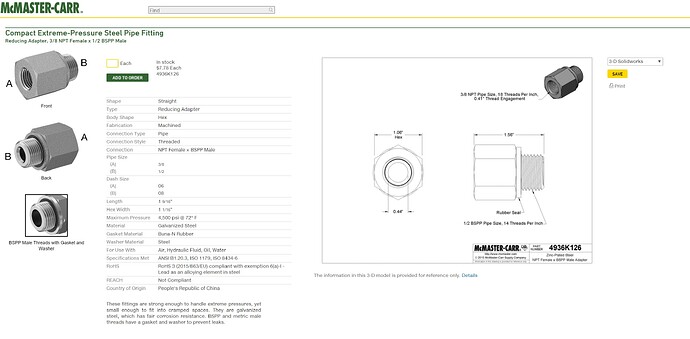

I ordered from McMaster Carr, pretty expensive to get fittings rated for our PSI usage. They’re a lot cheaper at hydraulichoses.com, but I’m relatively sure that the ID is smaller with theirs. I didn’t want to risk losing any flow, so I spent about $45 here

https://www.mcmaster.com/bspp-to-npt-pipe-fitting-adapters/extreme-pressure-stainless-steel-threaded-pipe-fittings-9/

Would this work? @Jake_Lambert @marinegrunt

3/8 1/2 06 08 4,500 psi @ 72° F Air, Hydraulic Fluid, Oil, Water ANSI B1.20.3, ISO 1179, ISO 8434-6 4936K126 7.78

Not that specific one in my case. My whips/K7/block are all 3/8. The K7 I bought is 3/8 female inlet, 3/8 male outlet. There’s not a lot to gain by running 1/2" lines if you’re constricting it to 3/8" at the unloader and block.

I should have specified for a ZK1. It has a

- 3/8" BSP-F inlet

- 1/2" BSP-M outlet

- 1/2" BSP-M bypass

Everyone in the US that’s ever attached a fitting to a General pump was threading NPT into BSP. Just think about that for a second!

I’m not challenging you personally in the slightest. You’re a good dude, knowledgeable and fair. A million people doing something wrong doesn’t make it right. You won’t find a single business or code authority that recommends mixing BSP and NPT under pressure.

Yes sir I hear you but I’m talking about real world experience. If I calculated my hours that I’ve ran General pumps with NPT you’d flip

I have zero experience with their actual pumps. But I do have experience with the K7 unloader I received, and 2 threads holding it together does not spell safety for me. I know that when I threaded my stainless 3/8 whip male into the 3/8 brass K7 female, it leaked… until I put a breaker bar over my wrench to deform the stainless male. That’s not normal, and it’s not safe. Actually the only leaks I had at all after my build were at the inlet and outlet of the K7. The threads are just different, we can make them “work”, but not as well as they were designed to

Bet it would work great. Heck, you can probably put loctite on any fitting, only hand tighten them, and they wouldn’t leak a drop.